Consumer Cheap PCB Fabrication and Assembly Fast PCB Assembly Panel Light

Cangzhou Yikang Food & Drug Plastic Packaging Company / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Soft Tooth Surface

- Installation:Vertical Type

- Layout:Expansion

- Gear Shape:Conical - Cylindrical Gear

- Step:Four-Step

=== Base Info ===

- Model NO.:pcba

- Type:Planetary Gear Reducer

- PCB Layer:1-26 Layers

- SMT Line Quantity: :30

- Solder Mask:Any

- Silk Screen:Any

- Surface Treatment:HASL

- PCB Assembly Type:SMT and DIP

- PCB Service:One Stop Service

- Small Orders:1 PCS Is Ok

- Copper Thickness:1oz

- Board Thickness:1.6mm

- Board Dimensions: Smallest Size:50*50mm

- BGA-Min Pitch:0.25mm

- Testing Procedures:Visual Inspection ; X-ray Inspection ;Aoi (Automat

- Board Shape:Rectangular ; Round ;Slots and Cut Outs; Complex a

- Lead Time:12-20 Days

- Transport Package:Vacuum+Carton Packing

- Specification:RoHS, ISO9001, UL, SGS

- Trademark:Fastline

- Origin:Shenzhen, China

- HS Code:8534009000

- Production Capacity:20000 Square Meter,Mon

=== Description ===

PCB Manufacture Capability

Note: Base on all data received by us and must be complete and problem-free, Lead time is ready to ship time.

PCBA Technology:

1)Professional Surface-mounting and Through-hole soldering Technology.

2)Various sizes like 1206,0805,0603,0201, 1005 components SMT technology.

3) ICT(In-Circuit Test), FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL, CE, FCC, RoHS Approval.

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line.

7) High density interconnected board placement technology capacity.

Types of Assembly: THD (Thru-Hole Device); SMT (Surface-Mount Technology) ; SMT & THD mixed; 2 sided SMT and THD assembly

SMT Line Quantity: 30

SMT Min Pitch-QFP: 0.3mm

BGA-Min Pitch: 0.25mm

Component Package: Reels; Cut tape; Tube and tray; Loose parts and bulk

Board dimensions: Smallest size: 50*50mm ; Largest size: 520*420mm

Board shape: Rectangular; Round; Slots and Cutouts; Complex and Irregular

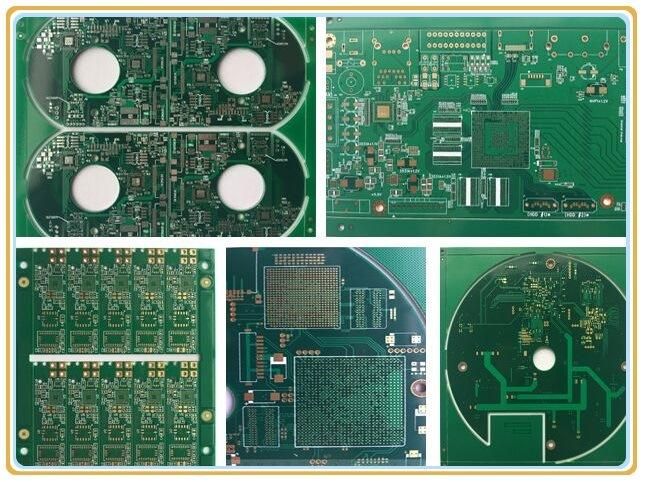

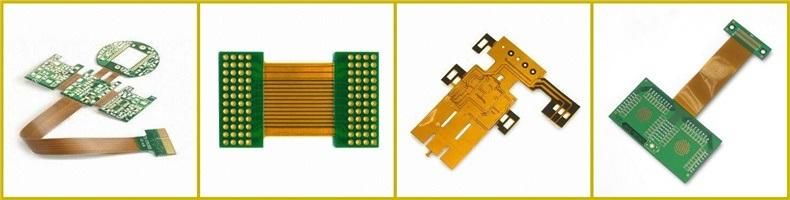

Board type: Rigid FR-4 ; Rigid-Flex boards ; Aluminum PCB

Assembly process: Lead-Free (RoHS)

Design file format: Gerber RS-274X ; BOM (Bill of Materials) (.xls, .csv, . xlsx)

Testing Procedures: Visual inspection; X-ray Inspection; AOI (Automated Optical Inspection); ICT (In-Circuit Test); Functional testing

Turnaround time: 1-5 workdays for only PCB assembly; 10-16 workdays for full turn-key PCB assembly.

Company Introduction

Fastline is a Leading PCB manufacturer in China. It was found in 2003, serving customers in over 40 countries from various electronic industries, Over 70% of products are exported to America, Europe and other Asia Pacific countries.

Fastline could meet all your PCB manufacturing needs, including High multilayer PCB, Aluminum based PCB, HDI PCB, Rigid-flex PCB, heavy copper PCB, and PCB assembly as well. Our products are widely applied in telecom, industrial control, power electronics, medical instrument, security electronics, aerospace and so on.

And provides "PCB One-stop PCB solution" to meet customers' diverse demands.

Our factories with a facility area of more than 40, 000 square meters with 1000 professional staff, And we have got the approval of ISO9001 certificates. UL Certification and all Products Meet RoHS compliance.

Fastline Circuits is commited to provide superior quality products and services that consistently meet and exceed our customer's requirements on time, every time!

Our Factory

PCB & FR4 PCB

PCBA

FAQ

Q1: Are you a factory or trade company?

A1: We have our own PCB manufacturing & Assembly factory.

Q2: What's your minimum order quantity?

A2: Our MOQ is not the same based on different items. Small orders are also welcome.

Q3: what file we should offer?

A3: PCB: Gerber file is better,( Protel, power PCB, PADs file), PCBA: Gerber file and BOM list.

Q4: No PCB file/GBR file, only have the PCB sample, can you produce it for me?

A4: Yes, we could help you to clone the PCB. Just send the sample PCB to us, we could clone the PCB design and work out it.

Q5: What any other information should be offered except for file?

A5: Following specifications are needed for the quotation:

a) Base material

b) Board thickness:

c) Copper thickness

d) Surface treatment:

e) color of solder mask and silkscreen

f) Quantity

Q6: I am very satisfied after I read your information, how can I start to purchase my order?

A6: Please click the "send" at the bottom of this page or contact our sales on Trade Manage online!

Q7: What is delivery terms and time?

A7: We usually use FOB terms and ship the goods in 7-30 days depending on your order quantity, customization.

For more information about PCB, please contact us!

Salesman: Cassie Qiu

Tel: +86 755 2332 9221

Fax: +86 755 2332 9659

Cellphone:+86 18028778060

Our website:http://fastlinepcb.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23