Dry Type Preparation Room and Spray Baking Cabin for Automotive

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Fully Undershot-type

- Heating Mode:Gas Heating

=== Base Info ===

- Paint Mist Treatment:Dry-type

- Condition:New

- Rear Wall:50mm Rock Wool Panels

- Plenum:600mm(H)

- Extraction:800mm

- Grids Carrying Capacity:700kg,Wheel

- Filter Areas:32m2

- Ceiling Lighting:8 Sets, Each 4 X 18W, 576W Total

- Brightness:> 700lux

- Air Volume:28,000m3,H, 650PA

- Overhead Infrared Lamps:Yes.

- Special Item:Rated Power: 10kw

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:6900 X 4900 X 2800mm (L W H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

PAINT BOOTH

BS EN 60204: 2006+A1:2009

BS EN 60204: 2006 + A1: 2009

failure indication

3.DETAILS

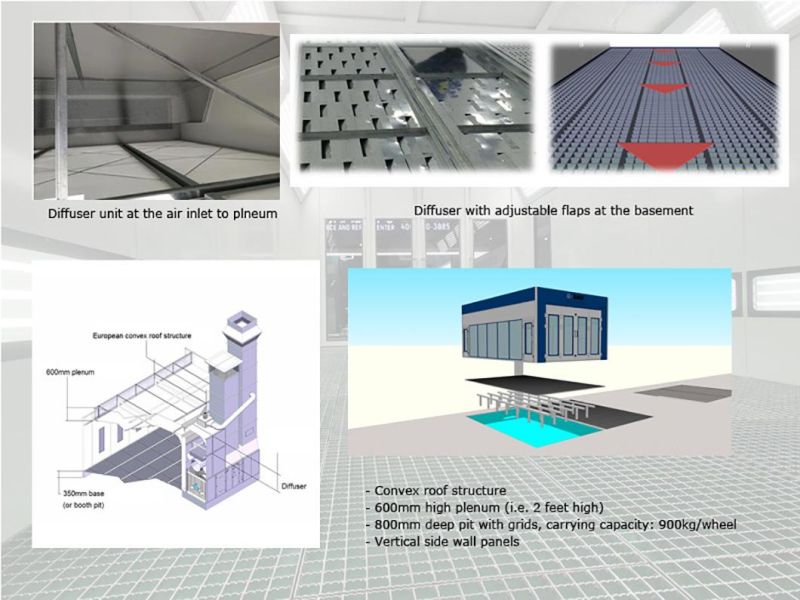

AIRFLOW & BOOTH STRUCTURE

- Downdraft airflow

- 600mm plenum

- Vertical walls.

- 800mm pit for extraction

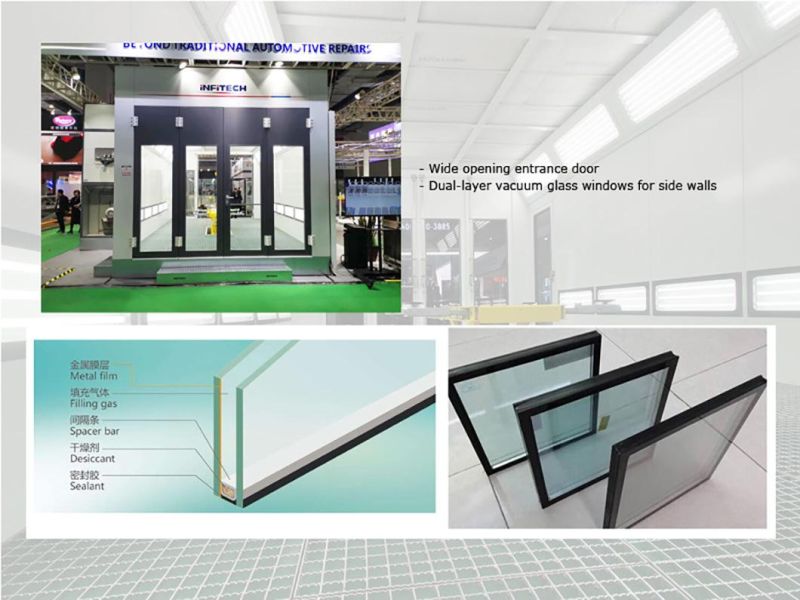

DOORS & WALLS

- 2+2 structure entry door: 3900x2700mm

- Side walls: dual-layer vacuum glass windows for side walls, convenient for observation during the training process

AIR INTAKE AND EXHAUST UNIT

- Non-spark fan & SIEMENS motor

- Cycle damper (for spraying and baking phase) - for paint booth

- 315KW heat exchanger and RIELLO gas burner RS5D - for paint booth

CONTROL

- Touch screen control panel with basic functions and safety functions

- SCHNEIDER inverter control

UPGRADE

- Traditional control panel with manual buttons

- Automatic pressure adjustment

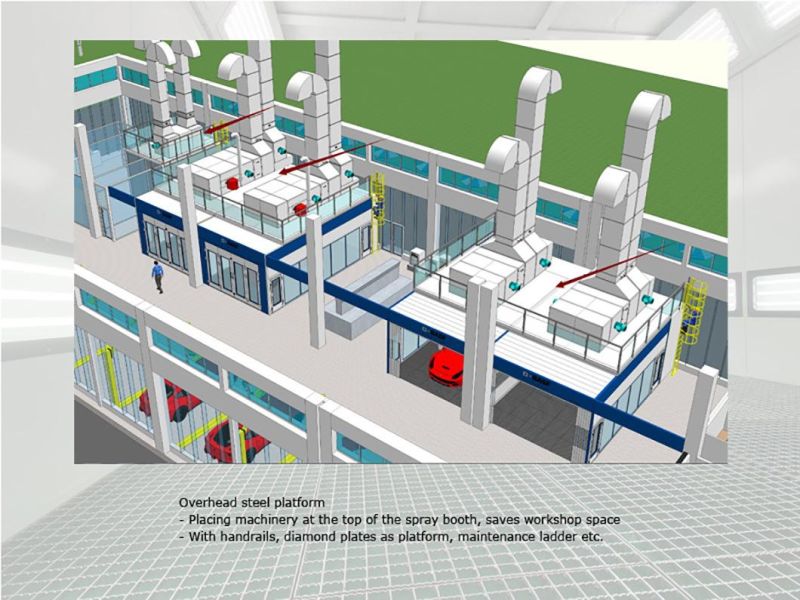

OVERHEAD STEEL PLATFORM

Application: for placing machinery at the top of spray booth, save workspace.

- Consists of support column, steel platform frame, skid-proof diamond plate, handrail, access stairs and access barriers.

- The loading capacity of the platform: 500kg/m2.

- The handrail adopts double layer vacuum tempered glass, with sound-proof protection device inside.

CONTROL BOX AND TOOL BOX (PREP STATION)

Arrangement: on the rear wall

OPTION

- The servo of central dust extraction unit can be integrated in the control panel

ELECTRIC SOFT CURTAIN DOOR & MANUAL SOFT CURTAINS (FOR PREP STATION)

FAQQ: I do not need to put the machinery at the top.A: That's okay. We can cater to your requirements. Please send your inquiry, and we will work out the ideal solution for you.

Q: Is the observation glass on the side walls heat insulation?A: Yes. It consists of two layers of tempered glass, and the middle is filled with gas. It can help preserve heat of the booth.

Q: Is paint mixing room available?A: Yes. Additionally, we can follow your supplied dimensions and layout for the paint mixing room.

Q: Do you also supply paint booth for industrial application?A: Certainly. Infitech provides coating solution for the automotive, and industrial manufacturing industry, including furniture, heavy machinery etc. And we have abundant experience in offering and delivering customized solutions.

Q: What about the warranty service?A: Infitech offers 2 year warranty for paint booths.

Q: How can I pay you?A: Please make the payment by T/T, 50% payment upon order confirmation, and balance before shipment.

Specially, we can also accept payment method of L/C, West Union etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23