Christmas Single Arm Solar LED Street Light (BDTYN09)

Yantai Changyou Glass Co., Ltd. / 2022-06-27

- Light Source:LED Lamp

- Lamp Body Material:Aluminum

- Light Type:Solar

- Color Temperature:Pure White

- Power:≥30W

- Technics:Diecasting

=== Base Info ===

- Model NO.:BD-TYN0009

- Illumination Time:10h

- Cell Type:Gel Battery

- Charging Time (H):10

- Usage:Garden, Street, Highway

- IP Rating:IP65

- Certification:CE, RoHS, ISO FCC

- Voltage:AC85-260V

- With Light Source:With Light Source

- Height:4-13m

- Color:Customized

- Brand:Baode

- Metal Protection:Hot Dipped Galvanized

- Average Thickness of Galvanization:86 Micron

- Wind Index:Grade 12

- Steel:Grade Q-235

- Product Name:Audited Suppliers Highly Recommended Solar LED Str

- Warranty:3-5years

- Application:Road

- Transport Package:Plastic and Box

- Specification:CE, ROHS, FCC

- Trademark:Baode

- Origin:Yangzhou Jiangsu

- HS Code:940540900

- Production Capacity:5000 Piece,Pieces Per Month

=== Description ===

Q345B/A572,minimum yield strength>=345n/mm2

Q235B/A36,minimum yield strength>=235n/mm2

Tolerance of Dimension

Lifter fixed in the inner of the pole with lifting speed of 3~5 meter per minute

Equipped e; ant ferromagnetism brake and break -proof device, manual operation applied under power cut

Electric Appliance Control Device

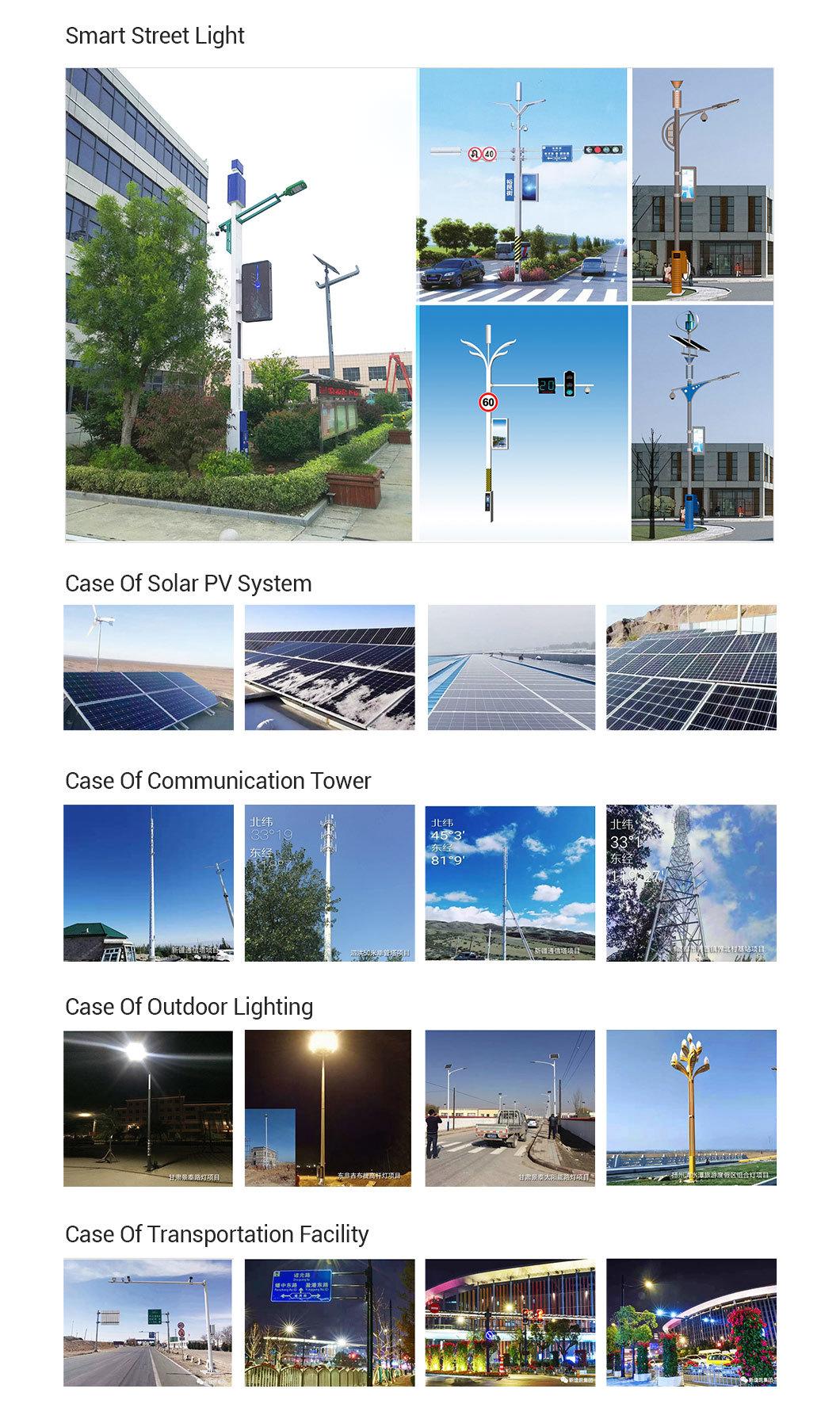

Our Projects:

Angola Seaport&plant area high mast lighting project |

Morocco Seaport high mast lighting project |

Bangladesh Seaport high mast lighting project |

Yangzhou Airport high mast lighting project |

Chengdu Airport high mast lighting project |

Beijing Airport high mast lighting project |

Company Information 21 Years Manufacturing Experience

Since 1998, we have started manufacturing street lighting. The 21 years' experiences have been a persuasive insurance for us to offer reliable products.

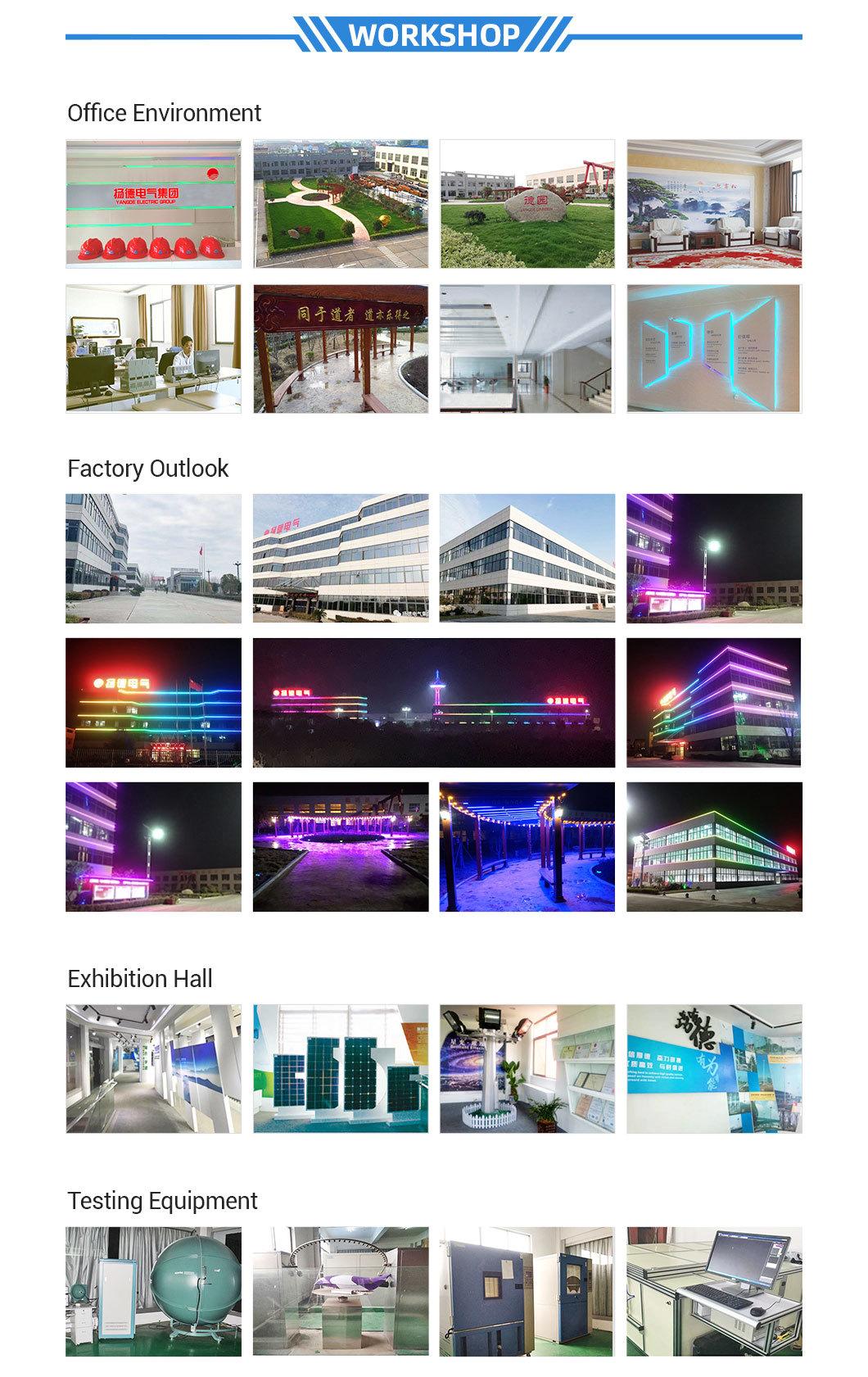

Large Factory with Complete Facility

We have 400 staffs with factory area 6000 m2. We also equipped with complete production and testing equipments, such as Steel Pole Rolling Machine, Spray Machine, Pressure Machine, Integrating Sphere, Lighting Simulating Machine and Weather-ability Testing Machines, etc . .

Our 60 experienced engineering team work with the PV institute of Shanghai FUDAN University , Shenzhen Foxconn to R&D outdoor lighting products. We have obtained over 20 national patents and built our own brand LUYOU.

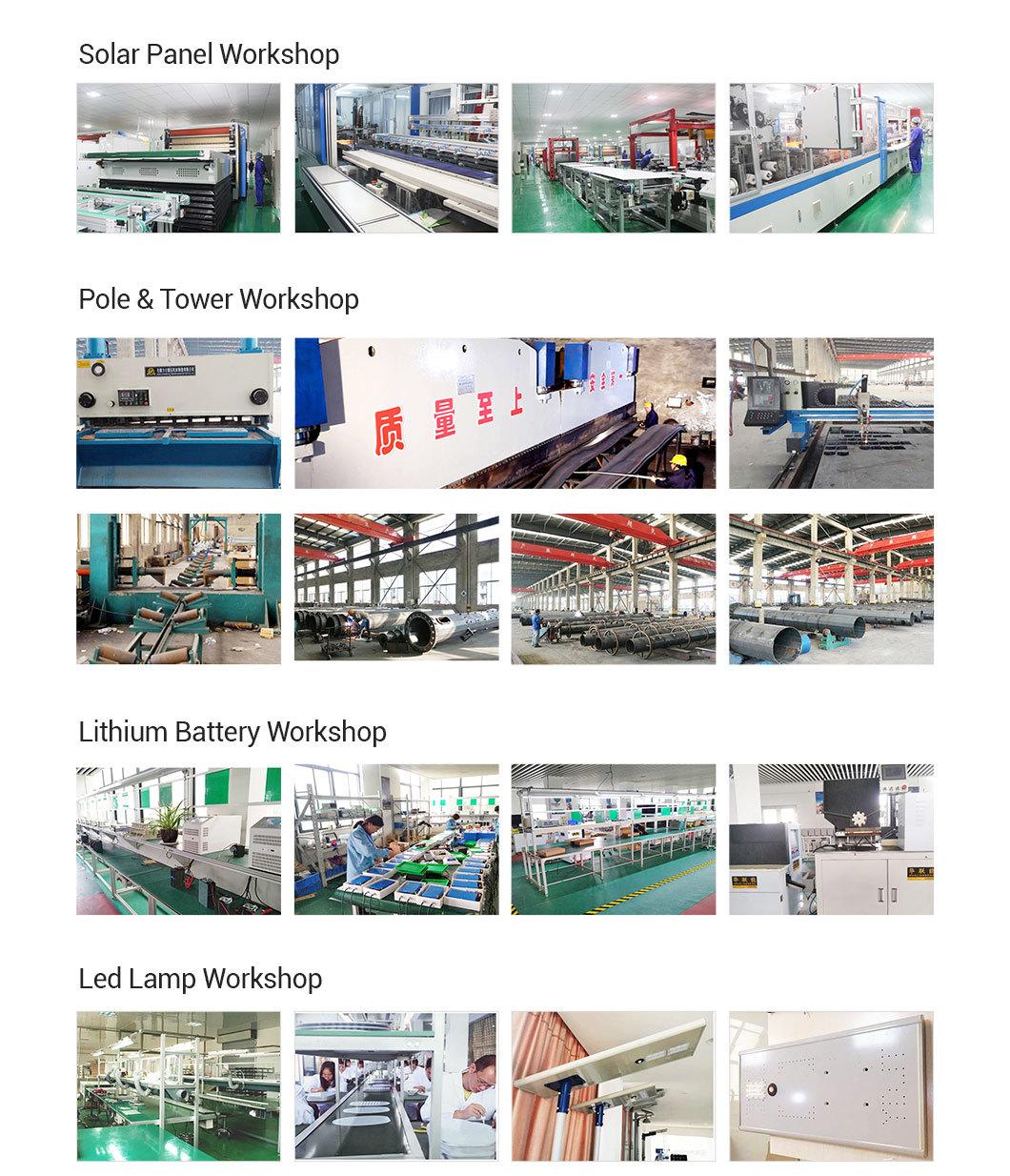

Manufacturing main components to save cost. BAODE manufactures the solar panel, light fixture and pole to control the cost and quality.

Factory outlet. There's no middleman between the manufacturer BAODE and domestic and oversea buyers.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23