Motorcycle Accessories Tapered Roller Bearings 30206 Bearing Price

Hengtailong Plastic Net Co. Ltd / 2022-06-08

- Rolling Body:Roller Bearings

- The Number of Rows:Single

- Outer Dimension:Small and Medium-Sized (60-115mm)

- Material:Bearing Steel

- Spherical:Non-Aligning Bearings

- Load Direction:Axial Bearing

=== Base Info ===

- Model NO.:30206

- Separated:Unseparated

- Inner Diameter:100mm

- Outer Diameter:180mm

- Sealing Type:Sealed or Not

- Breadth:34mm

- Rated Load:Cr:225kn Cor:240kn

- Weight:4.35kg

- Column Number:Single Row

- Transport Package:Cases and Pallets or as Customer′s Requirment

- Specification:customized

- Trademark:ZYS

- Origin:Luoyang, Henan, China

- HS Code:8482102000

- Production Capacity:10000000PCS,Year

=== Description ===

Overview

Product Description

Tapered roller bearings refer to the radial thrust rolling bearings whose rolling body is a tapered roller. There are two types of small Angle and large Angle. The taper Angle is mainly subjected to radial and axial combined loads, which are usually in double use and reverse installation. The inner and outer seat rings can be installed separately, and the radial and axial clearance can be adjusted during installation and use. The large cone Angle mainly bears the combined axial and radial load, which is not used to bear the pure axial load separately.

Product ParametersTechnical parameters of taper roller bearings:

The characteristics:

1. Enhance the interior design.

2. Special cage design.

3. Improve the accuracy and adjust the internal clearance.

4. Ring with locking slot design to prevent rotation.

Our Advantages

ZYS ADVANTAGES

Luoyang Bearing Research Institute Co., Ltd. is a high-tech enterprise specializing in the development of "high-rank, precise, advanced, unique, special" bearing products for the key units in various fields of national economic construction. Its predecessor, Luoyang Bearing Research Institute, was established in 1958. It is the only state-level comprehensive research institute in China's bearing industry. In 1999, it entered China National Machinery Industry Group Co., Ltd. and transformed into a science and technology enterprise.We have total assets of 2.06 billion RMB, own one research and development center, three industrial bases and cover an area of more than 47 hectares. We have advanced bearing manufacturing equipments and world first-class testing equipments and have solid strength in manufacturing, measuring and testing of bearing and related components with high precision and high reliability. We have more than 380 technical staff of bearing related disciplines, thus we maintain a leading position in the aspects of bearing design, basic theoretical research, lubrication technology, metallic and non-metallic materials, testing and industry standards.

ZYS Manufacturing capacity

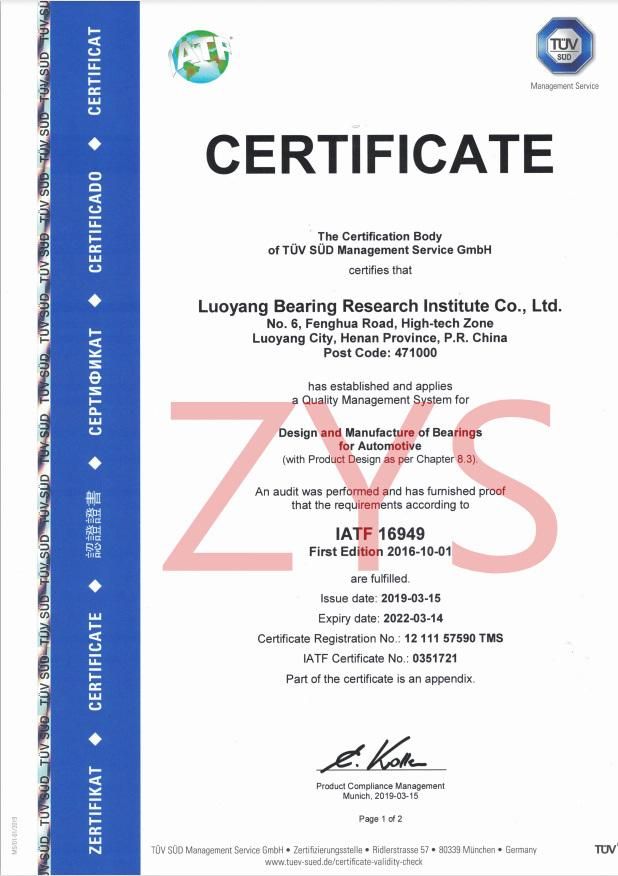

Certifications

CertificationsZYS QUALITY ASSURANCE

ZYS bearing products

FAQ

FAQQ: Are you trading company or manufacturer?

A: ZYS is bearing manufacturer, the only first-class comprehensive research institute in China bearing industry.Q: How do you control quality of bearing?

A: ZYS has established quality control systems for each kind of bearing and spindle. All products and services passed ISO9001-2008 Quality Certificate.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23