Luxury Table Top Furniture Emerald Green Marble Slab

Jiangsu Minnuo Special Equipment Co. Ltd / 2022-06-27

- Style:Modern

- Material:Stone

- Usage:Hotel, Home

- Shape:Square,Round,Oval, Rectangle etc

- Folded:Unfolded

- Rotary:Fixed

=== Base Info ===

- Color:Silver, Gold,Black, White ,Blue, Green,Multicolor, White, Black, Grey, Beige, Brown, Green, Red

- Customized:Customized

- Technics:Natural

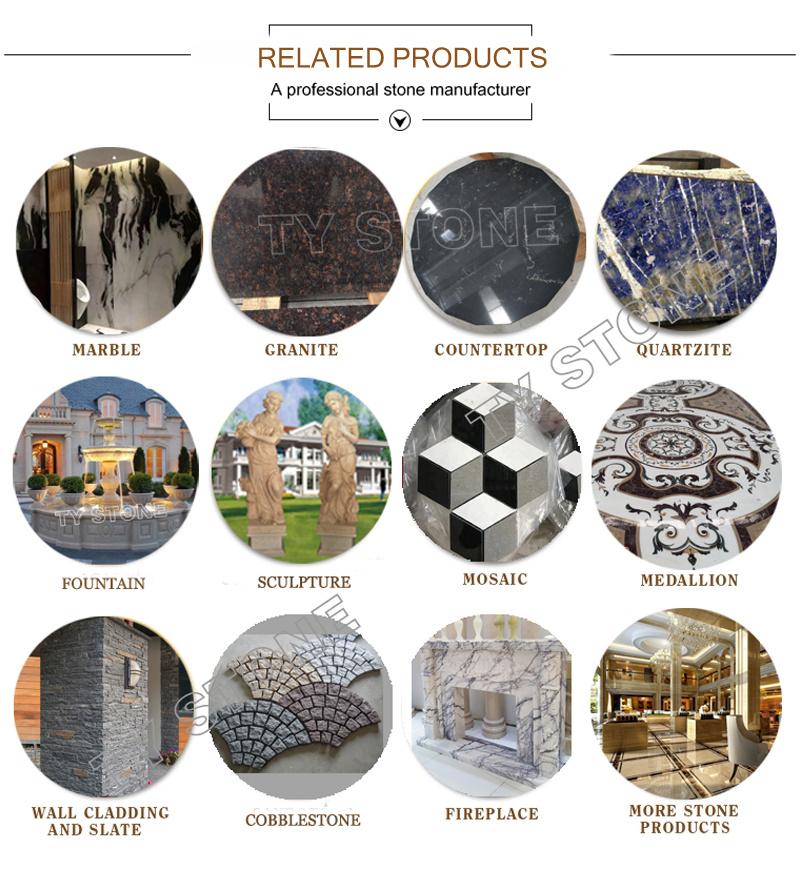

- Type:Marble, Natural Stone

- Surface Finishing:Polished, Honed, Tumbled, Sandblast etc

- Stone Form:Cut to Size Tiles, Slabs, Countertops

- Application:Floor, Wall, Kitchen, Bathroom Countertop

- Thickness:15mm, 18mm, 20mm, 30mm etc

- Thickness Tolerance:+-,1mm

- Advantage:Quality Assurance and OEM

- Scratches:High Resistance

- Sample:Free Provided

- Polish Degree:Over 85 Degree

- Service:OEM Support

- Free Sample:Available

- Waterabsortion:0.12%

- Supply Ability:20000 Square Meters Per Month

- Big Slab Size:120cmupx240cmup

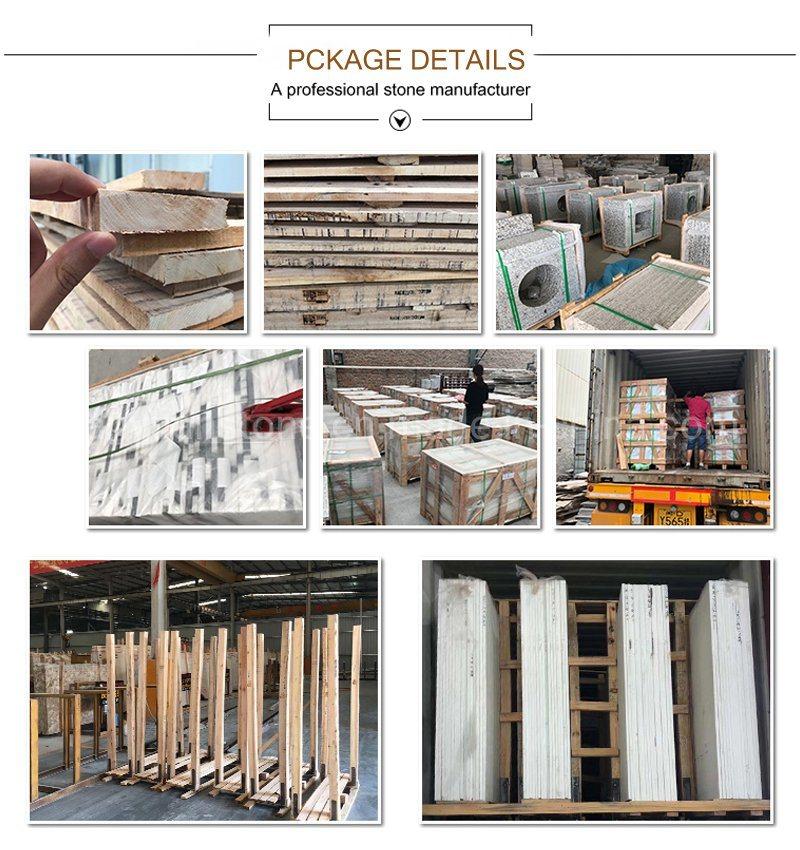

- Transport Package:Strong Wooden Crate with Fumigated

- Specification:0x60(24′′x24′′), 30.5x30.5(12′′x12") and custom

- Trademark:Tianyuan stone

- Origin:China

- HS Code:68029190

- Production Capacity:1000 Square Meters Per Month

=== Description ===

Size:

12' X 12",24' X 24",12' X 24",etc 300x300mm,300x600mm,400x400mm,600x600mm,etc

Surface:

During the whole production process, from material choosing, fabrication to package,

our QC will strictly control each piece and every process to ensure quality standards and on time delivery.

Our strict quality control for marble tiles. The following aspects are covered under marble inspection:

1. Checking for texture, color, spots, color lines and grainy/uniform crystal structure.

2. Inspection of surface finish - honed, flamed, polished, tumbled, bush hammered or more.

3. Checking for visible defects like scratches, broken edges, cracks, chipping, etching, pin holes, repair marks, swirl marks, etc.

4. Looking for other production defects, such as angle between adjacent edges, and intensity of polish and flatness.

5. Checking the length, thickness and width of the marble tile as per the specification or within the acceptable tolerance along

with diagonal length and angle control

.

Thin tiles are packed every 8 pcs per carton or foam boxes, and then in strong wooden crates.

Thick tiles are packed directly in wooden crates, with safe support to protect the surface& edges, and prevent rain and dust.

Slabs are packed in strong wooden bundles.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23