Infitech Prep Bays Preparation Bay Prep Station Paint Prep Bays

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- After-sales Service:24 Hours After Service

- Warranty:2 Years

- Type:Coating Production Line

- Certification:CE

- Substrate:Steel

- Brand:Infitech

=== Base Info ===

- Model NO.:YFT-D7000

- Coating:Painting

- Airflow Direction:Fully Undershot-type

- Heating Mode:Diesel

- Paint Mist Treatment:Dry-type

- Condition:New

- Color:as Requst

- Votage:380V

- LED Lamp:Optional

- Plate LED Lighting:Optional

- The Back Reflector:Optional

- Transport Package:Polyfoam and Metal Frame

- Specification:CE

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:500sets,Year

=== Description ===

Basic Info.

Model NO. YFT-D7000 Coating Painting Airflow Direction Fully Undershot-type Heating Mode Diesel Paint Mist Treatment Dry-type Condition New Color as Requst Votage 380V LED Lamp Optional Plate LED Lighting Optional The Back Reflector Optional Transport Package Polyfoam and Metal Frame Specification CE Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 500sets/YearProduct Description

Infitech Prep Bays Preparation Bay Prep Station Paint Prep BaysStart cabinet fan, the electric damper on exhaust pipe is opened. The air in work area through the air return system filter, the filtered air exhaust the cabin by fan exhaust pipe, and the small parts air sent into cabin top plenum by fan control.Plenum configure the second filter system(F5 ceiling filter cotton EN779, in the air suspended particles above 10μm filter and clean 100%, for suspended particles 1μm filtration efficiency up more than 20%, for suspended particles 5μm filtration efficiency up to 95%). Airflow run down from top through top filter system filtering and produce airflow in the booth, which made lots of mist, the dust and exhaust air drain away by air return collecting tank, the cycle like this keep booth cleaning.

Basic information

| STNDARD DESIGN | BS EN 13355:2004+A1:2009 BS EN 60204:2006+A1:2009 |

| CABIN STRUCTURE | |

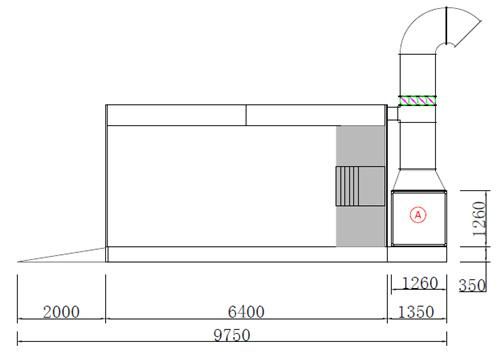

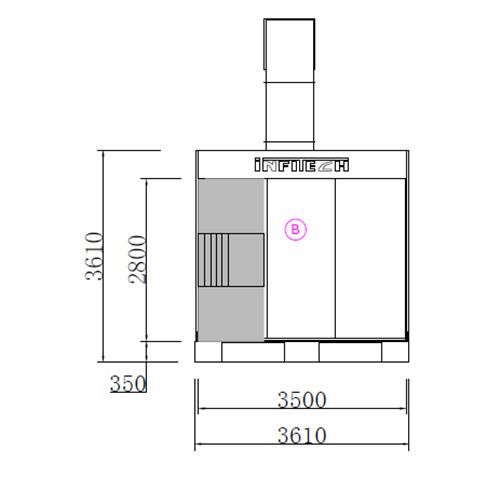

| Internal Dimension | 6300×3450×2800mm (L×W×H) |

| External Dimension | 7500×3550×3610mm(L×W×H) |

| BASEMENT | |

| Base Design Forming | Galvanized sheet plate bending forming,full grids Floor height 350mm |

| The carrying capacity of grid | 650kg/wheel |

| Filter area | 20m2 |

| Drive-in-ramps | X 2,each size:2000X520mm |

| Grid description | Size:997X756mm , 40X3mm Adopt suppressed type of steel grating |

| CABIN | |

| Wall panel | 50mm panel,wall panel filling material is EPS |

| PVC Soft curtain | (Colors: gray, blue, red, yellow) |

| Form of soft curtain | PVC curtain |

| Arrangement and number | 1 set of front, side 2 sets Color: middle transparent, yellow ends |

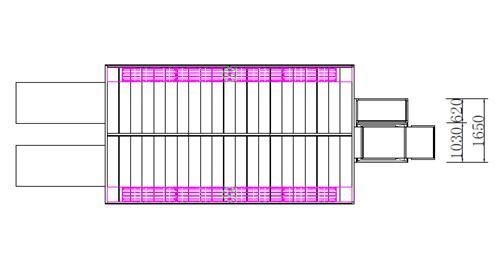

| CEILING LIGHTING | |

| Quantity and power | 8 sets the boxes, each 4X36W, a total of 1152W |

| Lighting arrange way | on both sides |

| Lighting description | Protection class IP55, CE certified electronic ballasts, OSRAM lamp |

| Brightness | >1000Lux |

| FILTRATION SYSTEM | |

| Pre-filter | Fiberglass paint-resistance filter, G2 grade |

| Ceiling filter | F5 grade filter cotton, SP-600G model |

| Bottom paint mist collecting | Fiberglass paint-resistance filter, G2 grade |

| EXHAUST SYSTEM | (Half-cycle) |

| Exhaust fan | Direct-type turbine fan |

| Fan power and motor description | 1×5.5KW,970RPM,380V,50HZ Motor through the CE standard |

| Parameter of exhaust fan | 18000m3/h ;650pa |

| PIPELINE CONFIGURATION | |

| Straight | 4 pieces |

| 90° | 1 piece |

| Reducers | 1 piece |

| CONTROL SYSTEM | |

| Implementation of standards | BS EN 60204:2006+A1:2009 |

| Features | Fan start, emergency stop switch, failure indication |

| SPECIAL ITEM | Rated power:6.5KW |

Design diagram for Infitech Prep Bays Preparation Bay Prep Station Paint Prep Bays

Factory Image:

Packing and loading:

SERVICE COMMITMENT

Before you buy

Product quality commitment:

1. Product manufacturing and testing have quality record and test files.

2. Product performance test. User will be invited to attend the complete test procedure. Once product is qualified, then to package and delivery.

Product price commitment:

1. Use famous brand raw material to ensure high reliability and advancement of product.

2. Under the equal race condition, our company sincerely provides the most favorable price and won`t be at the cost of reducing product performance and changing product components.

Are buying

Delivery time commitment:

Product delivery time:comply with customer`s requirement. If the goods need to be finished in advance, we will arrange production and erection to satisfy the customers.

After purchase

After purchase service commitment:

1. Service purpose: fast, decisive, exact, considerable, thorough.

2. Service target: service quality to win customer satisfaction.

3. Service principle: the warranty is 12 months, the supplier freely replaces damaged parts caused by quality reason within warranty. Beyond the warranty, the supplier provides spare parts at cost. If the equipment damages caused by human factors, the supplier repairs or provides spare parts at cost; our service people shall provide technical support at convenience.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23