Internal and External Circulation of Hydraulic Lower Homogenizer (seperated) PLC

Kunshan New Bright Commodity Co., Ltd. / 2022-07-05

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Milk

- Customized:Customized

=== Base Info ===

- Model NO.:ZT

- Model:100L

- Power:0.75kw

- Material:Stainless Steel

- Heating Method:Electric Heating

- Thickness:4mm

- MOQ:1set

- Polish:300 Mesh

- Jacket:Double

- Quality:Excellent

- Control:Button Control Panel

- Transport Package:Ply Wood Case

- Specification:Stainless steel

- Trademark:ZHITONG

- Origin:Guangzhou

- HS Code:8537101101

- Production Capacity:5000

=== Description ===

Basic Info.

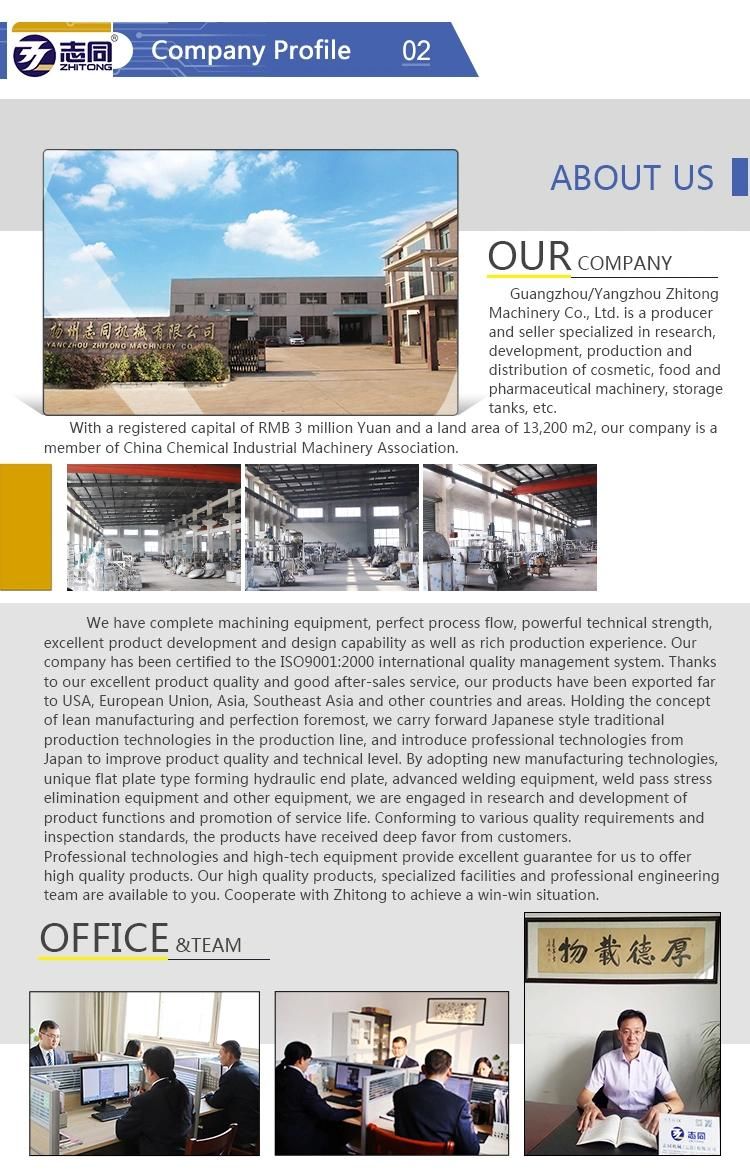

Model NO. ZT Model 100L Power 0.75kw Material Stainless Steel Heating Method Electric Heating Thickness 4mm MOQ 1set Polish 300 Mesh Jacket Double Quality Excellent Control Button Control Panel Transport Package Ply Wood Case Specification Stainless steel Trademark ZHITONG Origin Guangzhou HS Code 8537101101 Production Capacity 5000Product Description

Internal and external circulation of hydraulic lower homogenizer (seperated)PLC

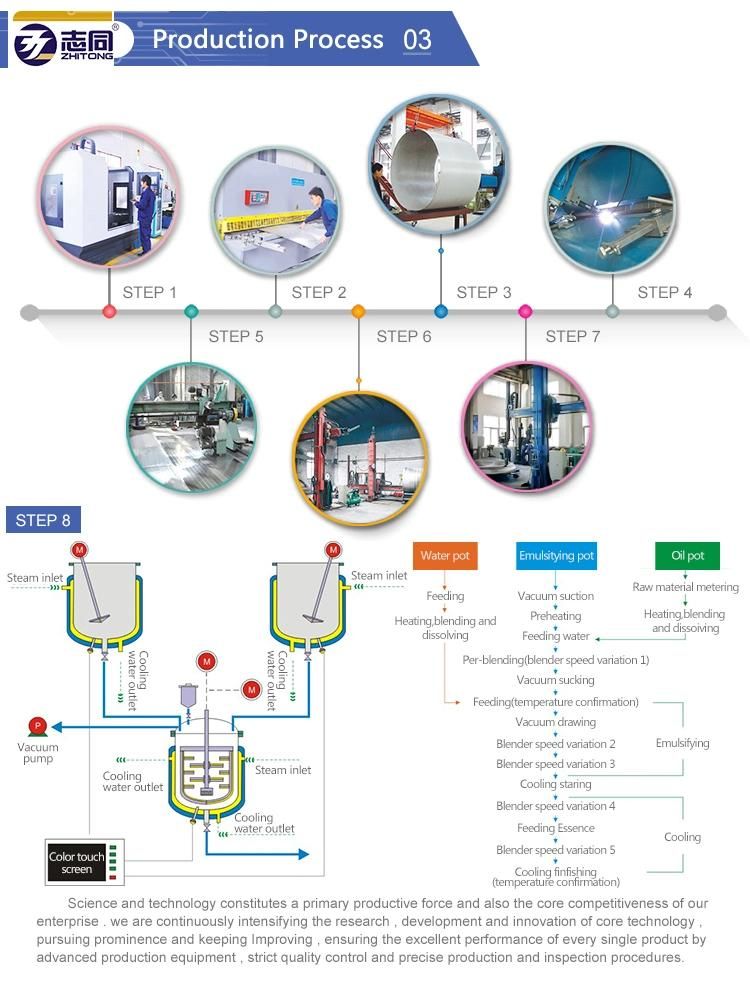

The material is stirred through the center of the upper part of the emulsifying pan, and the PTFE scraper plate always caters to the shape of the mixing pot, sweeps away the wall-sticking material, and causes the scraped material to produce a new interface continuously, and then cuts off, compresses and folds the blade and the rotating blade. Make it agitate, mix and flow down to the homogenizer below the pot, and the material is cut through the process of strong cutting, impact and turbulence between the high-speed rotating cutting wheel and the fixed cutting sleeve, and the material is cut in the shear seam. The particles of 200nm-2um were broken rapidly. Because of the vacuum in the emulsifying tank, the bubbles produced in the stirring process of the material were extracted in time. By means of vacuum extraction, the products produced are no longer mixed with bubbles in the stirring process, thus ensuring the production of high-quality products full of luster, fineness and good extensibility.

| Model | ZT-15KW |

| Motor | ABB Motor |

| Power | 15KW |

| Speed(RPM) | 2920 |

| Flow (M3/H) | <16 M3/H |

| Size of Pipe outlet | 50mm |

| Voltage | 380V 50HZ 3 Phase |

| Material | All parts are stainless steel except the motor, contact parts is SUS316L |

| Import and Export Caliber | Import :DN65 , Export: DN50 |

| Direction of Inlet and Outlet | Sucking in from Vertical, expelling from the radial direction |

| Protective Level | IP55 |

| Mechanical seals | Double mechanical seal, need to cooling water cooling mechanical seal |

| Static seal | Fluorous rubber, PTFE |

| Max allowable Temp. | 100 degree Celsius |

| Finish | Part of contacting material Ra0.4 and other parts Ra0.8 |

| Structure of rotor and stator | Rotor and stator occlude,material is SUS316L,3 group in all |

| Structure | Horizontally installing on the outside of vessel, contacting with pump and can process circularly |

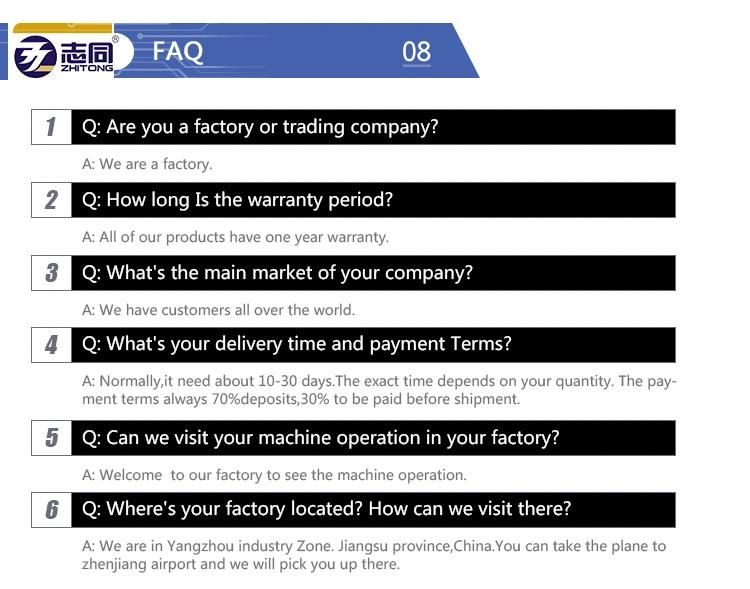

If you have any problem,please feel free to contact us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23