Featured Products Soys Protein Machine Soussage Meat Making Line

Qingdao Baigu Plastic Products Co., Ltd. / 2022-07-05

- Processing Material:Special Agricultural Products

- Customized:Customized

- Certification:CE, ISO9001

- Power Source:Electric

- Automatic Grade:Semi-Automatic

- Products:Soys Protein Machine

=== Base Info ===

- Transport Package:Wooden Cases and Plastic Film

- Specification:Stainless steel

- Trademark:SUNWARD

- Origin:China

- HS Code:8438800000

- Production Capacity:100kg,H -1000kg,H

=== Description ===

Basic Info.

Transport Package Wooden Cases and Plastic Film Specification Stainless steel Trademark SUNWARD Origin China HS Code 8438800000 Production Capacity 100kg/H -1000kg/HProduct Description

Soya protein meat analogue processing machine soybean nuggets production line Product Description

1. Machine introduction:

1.1Application: soys protein machine is to produce textured soy protein (TSP/TVP), soy meat, or soya meat, a meat analogue or nutritious meat . Soybean protein is made through a process known as extrusion cooking with defatted soy flour as raw material. After the soybean protein food is extruded from the dies of extruder plant the food is sliced into granules, flakes, chunks, nuggets, goulash, steakettes (schnitzel), etc. by revolving knives, and then is dried in a rotary dryer.

1.2Raw material of soys protein machine: textured soy protein machine adopt defatted soy flour, low-temperature soya flakes as raw materials

1.3 Using of soys protein machine can be used to produce soya nuggets, TVP/TSP, soya chunks by adjusting the molds from extruder; meanwhile, it can produce cereal, snacks by adjusting the screws from extruder

1.4Capacity of soys protein machine:100kg/h-150kg/h, 150kg/h-200kg/h, 200kg/h-260kg/h, 300kg/h-550kg/h,600kg/h-800kg/h,800kg/h-1200kg/h and so on.

| Model | TSE65-S | TSE85-S | TSE90-S | TSE95-S |

| Install Power(kw) | 90 | 160 | 195 | 220 |

| Consumption Power(kw/h) | 60 | 120 | 140 | 150 |

| Output(kg/h) | 200-260 | 300-550 | 600-800 | 800-1200 |

1.5Follow chart of soys protein machine: Mixing system---Extrusion system----Drying system (Frying System) --Packing system

1.6Voltage of soys protein machine:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

1.7Material of soys protein machine:

All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

2 Main machine information

2.1 Twin-screw extruder

1.The main extruder adopts frequency speed controlling with high automation.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system ,which can guarantee the equipment transmission life longer.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

5.It has the widest range of applications and can produce different products with different equipment and models.

2.2 Multi-layer dryer

1.We have four types of dryers, which includes fuel ovens, gas ovens, electric ovens, and high temperature inflated ovens (used to produce corn flakes).

2.The electric oven has three layers of five meters / five layers of five meters / five layers of eight meters / seven layers of eight meters / seven layers of eleven meters, etc., each layer has electric heating tubes,the purpose is to be more evenly heated.

3.Dryer is compact, has small dry area and a largesuperficial area. It also features small scale of heat elimination and high thermal effciency.

4.Mesh belt conveyors and thermal insulation boards all use stainless steel material, making the equipment clean and sanitary.

5. The speed of mesh belt conveyor is adjustable, the drying period for food in the oven can be adjusted.

6. The automatic temperature control system makes it possible to set the temperature according to your needs.

2.3 Cooling machine

1.General length is 5 meters, but we can made it according to our customers' requirement.

2.The above are fans, which used to speed up the cooling.

3.The goods are transferred by the belt while they are cooling by fans.

4.Material touching the food is stainless steel.

5.Transferring speed can be adjusted.

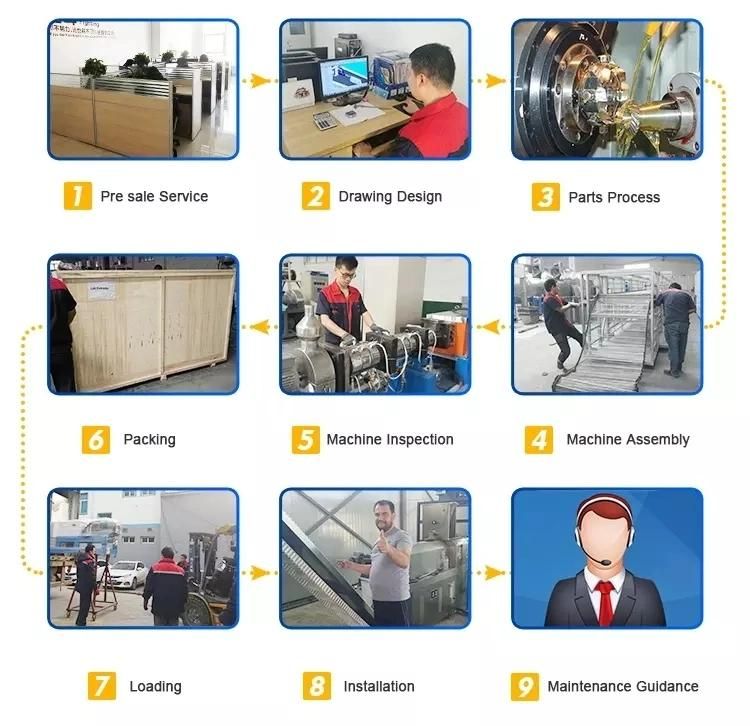

Packaging & Shipping

1. Testing Machine before package.

2. Packaging: inside is covered in plastic film, outside is wooden case.

3. Shipping: 15-35 working days after receiving deposit.

Jinan Sunward Machinery Co., Ltd is an industry and trade integrated enterprise. The company is committed to R & D extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system,soy nuggets system; as well as pet food/fish food system.

Jinan Sunward Machinery Company is founded in 2008. For supplying best service, technology department, Sales department, producing department , after- sales department are always available for you. Sales department includes two international sales department and two domestic sales department. One sale department is located in Wu Jia Pu Industrial Park,Jinan. The other sale department is located in No 130 Wu Ying Shan Middle Road, Jinan.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. Machines are welcome in the countries. So until now, there are not only direct customers, but also some long term cooperation agents. Such as Indonesia agent, Iran agent, Nigeria agent and so on.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23