High Power Laser Cutting for Tinplate and Silicon Steel Sheet

Fuzhou Wasendar Paper Craft Products Co., Ltd. / 2022-06-23

- After-sales Service:Online Support

- Warranty:12 Month

- Application:Environmental Equipment, Agriculture Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry

- Cooling System:Water Cooling

- Technical Class:Pulse Laser

- Applicable Material:Metal

=== Base Info ===

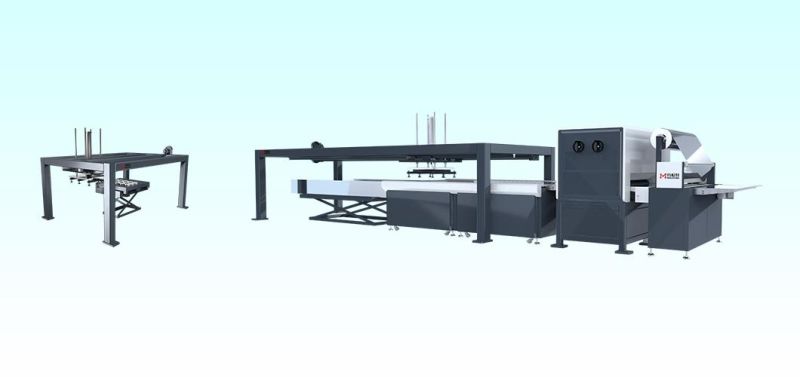

- Model NO.:MHTS

- Structure Type:Gantry Type

- Laser Classification:Fiber Laser

- Laser Technology:Laser Control Fault Cutting

- Cutting Thickness:1-30mm

- Certification:CE

- CNC or Not:Yes

- Control Method:Cypcut

- Focus Method:Following and Automatic Adjust Focus

- Transport Package:Wooden Case Package

- Specification:1000-12000W

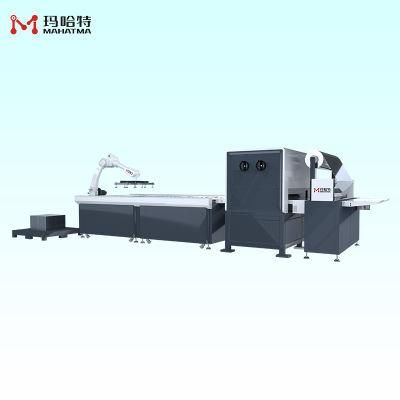

- Trademark:MAHATMA

- Origin:China

- HS Code:8462219000

- Production Capacity:500 Set,Year

=== Description ===

Overview

Detailed Photos

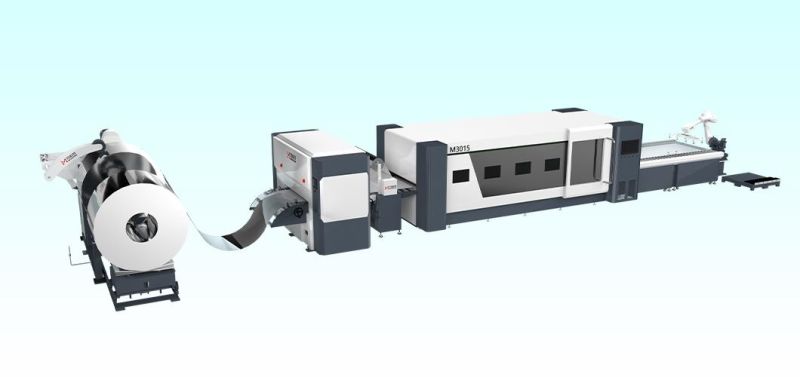

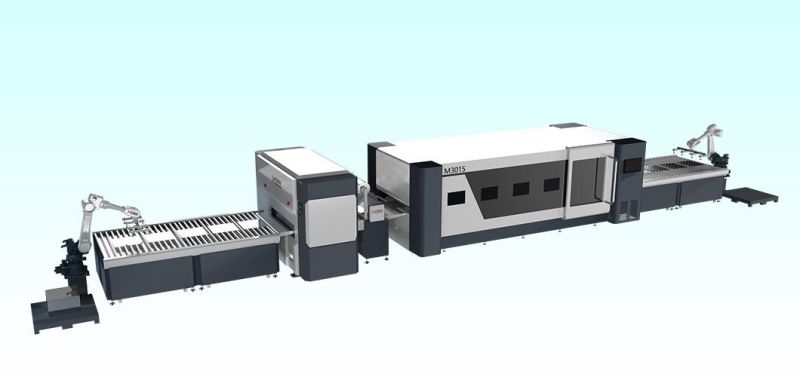

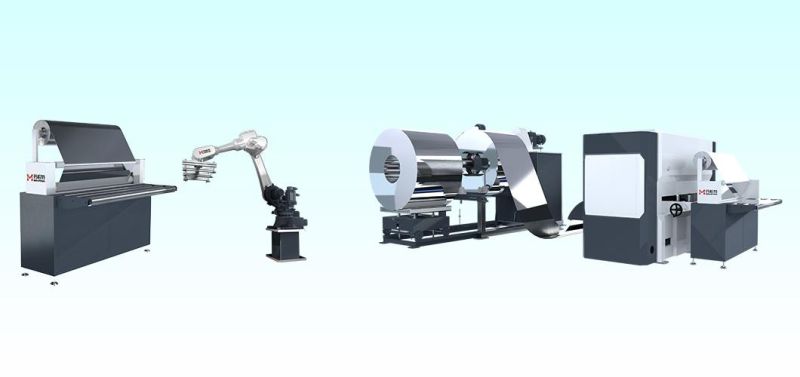

Mahatma - is a high-end automation brand operated by Guangdong (Jiangxi) Mahatma Technology Co., Ltd. -- A high-tech enterprise dedicated to R&D, production and sales of high - precision leveling machines and supporting peripheral equipment . Introduce German and Swiss precision leveling/straightening equipment technology, and cooperate with many universities and research institutes in production, learning, and research to continuously carry out technological innovation and production improvement, and combine the needs of many metal precision parts manufacturing enterprises to adopt innovation design ideas, advanced manufacturing technology, R&D and production: servo CNC high-precision leveling machine , laser cutting machine, automatic loading and unloading manipulator, robot, laser leveling detector, High-precision uncoiling, leveling, stamping and shearing line and laser cutting and other automatic production lines. Mahatma has accumulated 20 years of industry experience, the leveling accuracy has reached the most advanced level in the world, and a number of technologies are the first in the industry! Eliminate the internal stress of materials, restore and improve the flatness of parts for customers, and realize low-cost, high-efficiency and high-quality fully automated leveling equipment for subsequent bending, welding and other processes, which has brought a strong gospel to the majority of enterprises. It is used for the cabin cabinets, automobile and motorcycle accessories, transportation, aerospace , sheet metal processing, construction industry, medical technology industry, electric power and electrical, textile machinery, building materials, ceiling curtain walls, 5G communications, circuit boards, electronic parts, fixtures, saw blade substrates, etc. Well-known companies in the industry provide solutions.

With the Commencement and operation of Jiangxi Fuzhou Industrial Park, and the establishment of Mahat's Kunshan, Qingdao, and Ningbo branches, the company will have greater improvements in brand, strategy, development, production capacity, and service. Ningbo, Chengdu, Xi'an, Changsha, Wuhan, Harbin, Shijiazhuang, Xiamen and other parts of the country have established branches to establish service bases.

Continue to innovate, strive for excellence, continuously improve quality, efficiency and brand influence, vigorously promote brand internationalization strategies, cultivate new advantages in global technological competition, strive to build a Chinese industrial brand with international brands, and continuously improve brand value of enterprise and "Made in China" .

Mahatma has accumulated 20 years of product precipitation and the powerful combination of domestic and foreign experts, colleges and universities, mastered the main technology of the product process, and created a new era of leveling machines. As the company's philosophy, we are determined to become the most professional manufacturer of metal finishing equipment for domestic and foreign brands, and provide cost-effective equipment and services for global manufacturing companies! ! !

After Sales ServicePre-sale Service:

According to customer needs, from the customer's point to provide customers with accurate technical parameters of the leveler, customize products for customers, answer all the questions raised by customers; From the technical feasibility point, to assist customers to do a good job in engineering planning and system requirements analysis, so that our products can maximize to meet the needs of users. At the same time to provide free proofing, and we have the sample leveling base for customers to visit the site. So that customers more directly to make accurate business decisions, open up new markets.

On-the-job Training:After the signing of the sales contract, according to the specific requirements of the customer, our company will provide consumers with free debugging and on-site training after debugging. Finally let the customer responsible for the leveler equipment related technical personnel, fully master the technical characteristics of our company leveler equipment, operating procedures, maintenance of common sense, our trainer can be evacuated.

After-sale Service:1. Organize the personnel to install and debug the products and train the user operators within the specified time as required by the sales contract.2. According to the requirements of the contract and technical agreement, we will repair or replace the corresponding spare parts for users free of charge for all kinds of faults or parts damage caused by the quality problems such as product manufacturing, assembly and materials during the warranty period.3. Regularly organize personnel to visit key sales areas and key customers, understand the use of products, and solicit users' opinions on product design, assembly, process, etc.4.Ensure that the products provided to customers are brand-new products of the original factory; And for products, the warranty period is one year; During the warranty period, if the supplier's products have non-human mechanical failure and natural damage under normal use, our company shall be responsible for free maintenance or replacement; If the customer's fault is caused by improper human warranty and force majeure, the cost shall be charged; During the warranty period, if there is a fault in the equipment, our company will first communicate by telephone after receiving the customer's notice. If the problem cannot be solved by telephone communication, we will send someone to the site to eliminate the fault within 48 hours.

Exhibition

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23