15%PP/PE+80% CaCO3 +5%Additives Mfi 4-10 High Filler Masterbatch Machine

ShunDe Jiatian Hard Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. TSE SERIES Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Color as Required Application Granules Voltage 220V/380V Power(W) 55kw Weight 3000kgh After-Sales Service Provided Engineers Available to Service Machinery Overseas Screw Material Stainleeless Steel Warranty 1 Year Diameter of Screw 50.5 mm Screen Changer Hydrulic Screw Changer Transport Package Wood Case Specification CE ISO9001 Trademark Nanjing kairong Origin China (Mainland) Jiangsu, Nanjing City HS Code 84772090 Production Capacity 300 Sets/YearProduct Description

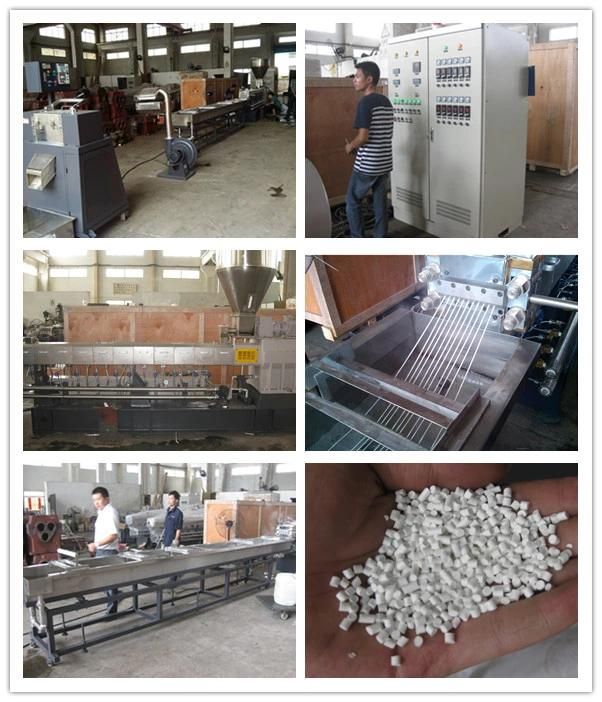

Caco3 plastic filler masterbatch making machine

Parameter geanulator

Mode mm L/D R/MIN KW N.m KG/H

TSE-20 22 32-44 600 5.5 43 1-10

TSE-30A 31 32-48 600 15 119 5-40

TSE-40A 41 32-52 600 15 119 65-110

TSE-40B 41 32-52 400 22 263 90-150

TSE-52B 51.5 32-64 600 75 716 250-300

TSE-75B 71 32-64 600 132 1050 350-550

TSE-75D 71 32-64 600 220-250 1990 500-1000

TSE-95A 93 32-64 500 250 2387 600-1000

TSE-95B 93 32-64 600 315 2506 800-1200

Application of masterbatch machine

a. For high filling masterbatch : PE/PP/EVA ,+ Caco3, Tio2, Talc,Carbon Black , etc;

b. For fiber reinforcement: PP/PA/PBT/ABS/AS/PC/POM/PPS/PET +glass fiber, carbon black ;

c. For color masterbatch: PE/ABS/PS/EVA/PET/PP +Pigment, addictives;

PP + 30% Pigments+ Calcium carbonate + Addictives;

a.Including mixer for mixing PE+ pigments +Calcium Carbonate Addictives;

b.Screw loader for loading materials;

c.Extruder for extrusion ;

d.Water strand pelletizing line for cooling and cutting;

PP +70% Calcium carbonate ;

High speed mixer for mixing PE+ Caco3+ Addictives;

Screw loader for loading materials ,

Extruder for extrusion;

Water ring pelletizing line for cooling and pelletizing ;

PE + 85% Calcium carbonate;

Including High speed mixer for mixing PE+85% Calcium carbonate+ addictives;

Screw loader for loading materials ;

Extruder for extrusion;

Air cooling pelletizing line for cooling and cutting ;

1. Electric control system of recycled ldpe plastic granules Frame structure control cabinet Imported electrical elements Imported temperature control system Imported driving system Interlock and multi-protection Adopting imported PLC (OMRON or SIMES ) to achieve optimized process control.Stronger function, steady performance and much higher accuracy. It can be also accomplished full-set link-lock protection,trouble safeguard, fault alarm cluing and so on Operation interface on touching screen is visual and marked, which is brief and easy to use. 2.The Gearbox of recycled ldpe plastic granules New-style project of parallel three-axises driving makes the convey axis,convey chain,decelerate and the torque assignment get together,which keeo it compact,and the key bearings are imported. The select material of drive components is dainty. Including super intension alloy cementiteing steel,cementiting and quenching ,gear grinding technics ,strengthening of tooth face.So they can ensure high torque,high precision and low noise. Soakage and coerce lubrication integrate smoothly.When the hydraulic circuit is over pressed, it alarms

3.Mixing and Feeding system of recycled ldpe plastic granules

According to the material and special techinics demands,the material of cylinder can use high quality nitrided steel,corrosion proof or antifriction with corresponding processThe screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treamen

the water strand is suitable for plastic recycling

the water strand is suitable for plastic recycling

Our Serivice

Before-saleIntroduce products in detailsRecommend suitbale solutionOffer test During manufacturing:Provide layout and engineering conditionsOffer screw plan and related documentsInform the project processing statusInsure the product designed in accordance with technical document After-sale:Provide installation,commissiong and trainingOffer spare partsProvide necessary technical support and update information 1.Quality guaranteed 2.Support factory visit 3.Technology supports 4.We are the manufactuer

FAQ

1. Q: How can we go to your factory? R:Our factory is located in Nanjing jiangning, Jiangsu Province, China, 1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport; about 20 mintues to our company 2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.about 8 mintues to our company All our clients, from domestic or abroad, are warmly welcome to visit us! 2. Q: Why chose us? R: 1)Quick reply. Once we received the inquiry from Alibaba, we will reply you within 24hours. 2)Quick manufacturing time. To guarantee the quality, the machine will be finished within 60days. 3) Before delivery, the machine will be tested to ensure every part is ok. 4) Wooden case package to ensure no damage during shipping. 3.Q:What is the payment? R: 1) T/T payment; 2) LC;

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23