Food Grade Stainless Steel Beer Making Equipment with Digital Display Control

Hangzhou Panache Import and Export Co., Ltd. / 2022-07-05

- After-sales Service:3 Year

- Warranty:12 Months

- Condition:New

- Customized:Customized

- Voltage:3 Phase, 380V 50Hz , 220V 60Hz

- Composition:Brew Beer Equipment

=== Base Info ===

- Model NO.:CJ-500

- Processing Material:Stainless Steel 304

- Process:Ferment

- Key Selling Points:Competitive Price

- Capacity:1000L

- Power:0-80kw

- Motor:0.75kw

- Dimension(L*W*H):Depends on Buyer

- Weight:200kg-2000kg

- Keywords 1:Beer Brewing Equipment, Beer Making Machine

- Keywords 2:Beer Making Machine, Craft Brewery Equipment

- Appliance:Brew Bar, Brewery, Hotel

- Heating Way:Steam or Electricity

- Certificate:TUV CE ISO

- Polishing:Less Than 0.4 μm

- Manway:Top or Side

- Insulation:50-100 Polyurethane

- Washing:360 Degree Spray Ball

- Transport Package:Steel Frame

- Specification:800x800x2100

- Trademark:brew kettle

- Origin:China Jinan

- HS Code:8438400000

- Production Capacity:50set Per Year

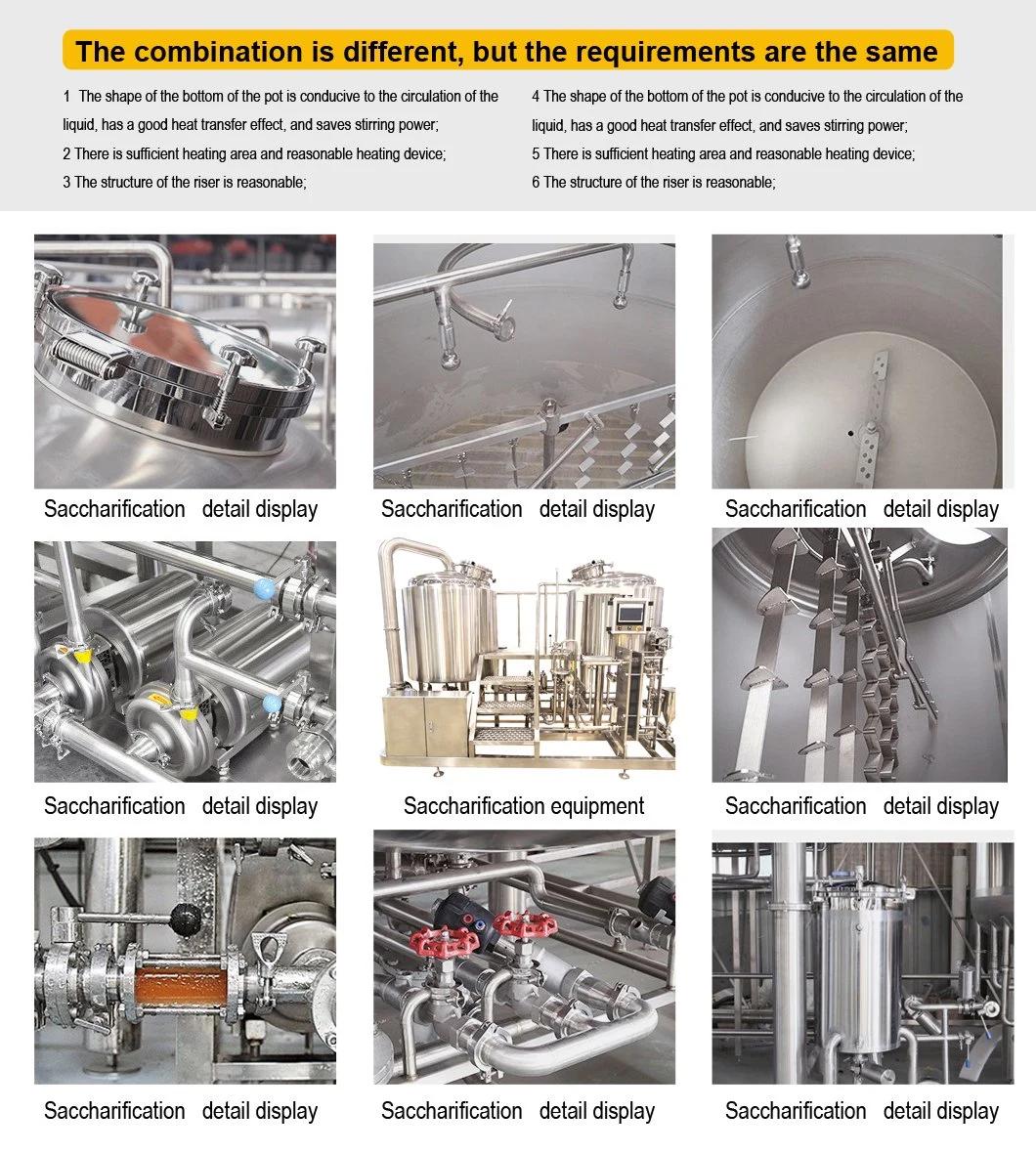

=== Description === Saccharification system of 500L beer equipment

Saccharification system of 500L beer equipment

Germany beer equipment:

Mash Boiling Kettle + Lauter Whirlpool tank

American beer equipment:

Mash Lauter Tun + Boiling Whirlpool Kettle

The two-vessel combination is generally including: German and American styles. The German style is that the saccharification and boiling process are in one kettle, and the lauter and whirlpool process are in another tank; the American style is saccharification and filtration in one pot, and the boiling and precipitation are in another pot.

The advantages of the combination of the two devices: low equipment cost, simple process, convenient operation, compact equipment layout, small footprint, modular design, and convenient installation and transportation.

The disadvantage is that the production efficiency is low, and only 2-3 batches can be produced per day.

Saccharification system of 500L three-vessel combined beer equipment

Mode 1:

Saccharification boiling Kettle + Lauter Tun + Whirlpool tank

Mode 2:

Saccharification Kettle + Lauter Tun + boiling Whirlpool tank

Mode 3:

Saccharification Lauter tank + boiling Kettle + Whirlpool tank

Traditional Brewery Generally Seldom Adopt the three-vessel combination beer equipment. The three-vessel combination appears more because of the development of the craft brewing industry, and the form is more flexible on the basis of the two-vessel combination beer equipment. The daily production can reach 4-6 batches.

Fermentation system

Fermentation system

1. The fermentation system mainly includes fermentation tanks, sake tanks and yeast expansion equipment. The beer and wine fermentation system adopts different beer fermentation processes. Processed with 2mm 304 stainless steel plate, cooling medium: alcohol water, tank with sight glass, one inlet and outlet at the bottom, double-acting vacuum safety valve, diaphragm pressure gauge installed on the top, closed sight glass, one backup pressure exhaust and CIP port , Internally connected to the washing ball, external pressure exhaust pipe and CIP pipe, the tank has a sterile sampling valve and Pt100 platinum resistance, with 80 Rumi sight glass spotlight. The cold-rolled elliptical upper head is beautiful and has no dead corners for cleaning;

Controlling System

Controlling System

The craft beer equipment control system is the core part of the entire brewing process, including: malt crushing, saccharification, fermentation, cooling, temperature control, pressure control, refrigeration and other important systems and the overall control of other auxiliary control systems, which can realize partial control Or comprehensive PLC automatic control.

The control system adopts the beer intelligent PLC control system and intelligent control system independently developed and patented by the company. It is composed of Siemens programmable controller PLC, industrial computer, automatic control components, power distribution cabinet, and operation console. It can also control the material flow manually on the operation console. It can be controlled automatically or manually according to customer requirements.

This system adopts the upper and lower levels of computer control, adopts the Siemens STEP7 series programmable controller that was widely used internationally in the 1990s, and combines with the high-reliability industrial computer to form a powerful control system. Industrial computer real-time display, storage, query, control or modification of each process parameter to make the entire equipment in the best state; the lower control level is composed of SIMATIC STEP7-300PLC

In this system, various signals include: liquid level switch, valve position, motor, pump and other switching signals, as well as temperature and other analog signals, all enter the PLC. The PLC automatically completes the various switches according to the program set by the process requirements. The output signal completes the control of actuators such as butterfly valves, solenoid valves, pumps, reducers, etc., and completes the technological process. The communication between the upper computer and the lower computer adopts the DIN standard PROFIBUS-DP bus, which can be easily connected with other control systems for unified management. The CIP cleaning system of a small brewery can be equipped with different types of cleaning systems according to the scale of the equipment. There are two modes of CIP cleaning workshop and simple disinfection device for you to choose.

The CIP cleaning system of a small brewery can be equipped with different types of cleaning systems according to the scale of the equipment. There are two modes of CIP cleaning workshop and simple disinfection device for you to choose.

1. The CIP cleaning workshop is suitable for large-scale and large-volume factories. It is generally composed of lye tank, acid tank, aseptic water tank and disinfection tank. The tank body is made of stainless steel welding. The system has the characteristics of compact structure, convenient installation and maintenance, and can effectively control the tank container. Production equipment such as pipelines and pipelines are cleaned in situ. The entire cleaning process runs in closed production equipment, tank containers and pipelines, which greatly reduces the chance of secondary pollution and has a small footprint, saves operating time and improves efficiency. ; Save labor and ensure safe operation; save water, steam and other energy, reduce the amount of detergent production equipment can achieve large-scale, high level of automation to extend the service life of production equipment.

2. Small-scale production factories can also use simple CIP disinfection devices, including alkali tanks, sterilization water tanks and sanitary cleaning pumps. This device can fix the alkali tank, sterilization water tank, cleaning pump, pipe fittings and valves on a small cart, or it can be customized for you according to the scale of the equipment. The operation is flexible and simple, and it can be used in the cleaning and disinfection of various types of small brewery equipment, so that it can achieve the characteristics of thorough disinfection and no dead ends. At the same time, the equipment can also be equipped with manual, semi-automatic and fully automatic operation according to different customer requirements.

Our Service

- Customized according to your personal request based on our standard configuration

- After Sale Service for whole life if you have request

- 24hours on line, supply solutions any time

- 3 Years Warranty for the Main Equipment

- Spares parts replacement and repair service

- Engineer goes to your city for installation, debugging and brewing training if you need

- Provide the import documents that you need for customs clearance and reduce Tax.

- Supply the latest news for the brewing industry and brewing technology

- Port to Port, Door to Door service

What's Your Brewing Plan?

To offer you the suitable equipment with favorable price, would you please help confirming the following:

- What is your area for the project?

2. What about your local Power supply? 220v 1p 50hz, 380v 3p 50hz,220v 3p 60hz ?

3. What about your time plan ? Usually the production need 35-50 Days

4. You need the Brewhouse with 2 or 3 vessels type ? or others?

5. How many Fermentation Tanks Needed ? 1:1 or 1:2

6. Would you like to with the Bright Tanks too?

- Where will be the nearest destination Port if you need to know the freight cost ?

- Would you need the electric appliance with UL or others certificate ?

FAQ:

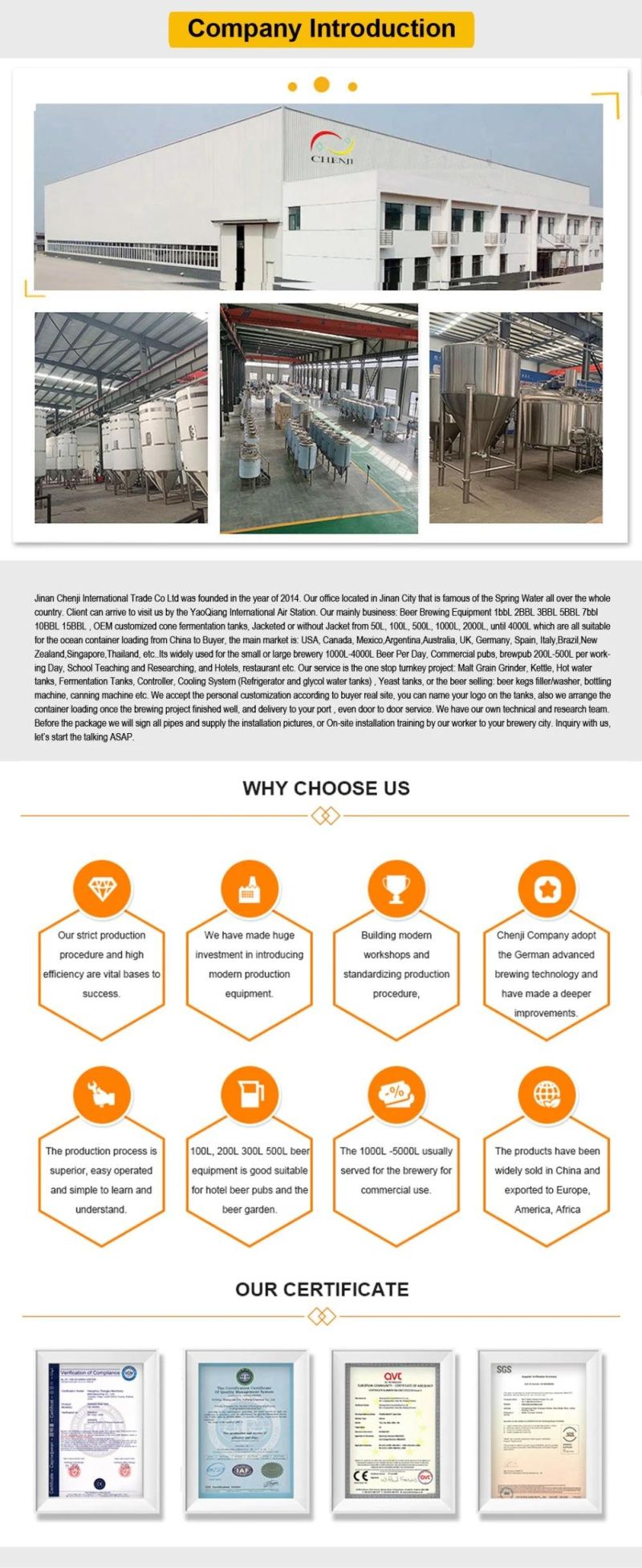

1.Q: Are you professional Supplier and tanks Manufacture ?

A: We are the manufacturer of beer brewing equipment for 15 Year and deal in export business since 10 years ago .

2.Q:Can I have the customized products with personal design?

A:Yes,we support any of your wish design,can design and manufacture as client's requirements.

3.Q: Can you guarantee your beer brewing system quality?

A: All of the equipment will be inspected before the package, appliance of the international Standard.

4.Q:How about the after sales service?

A:For our after-sale service, we promise all life of technical support to all client.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.

5.Q: Which export port you use?

A:Commonly we will use Qingdao port, sometime, can be other port as your wish.

6.Q: I am green hand in brewery industry? Could you supply training for us?

A: Yes, our engineer can supply the installation equipment and brewery training service overseas.

7.Q: what is your payment item ?

A: We accept 40%TT + 60%TT as for the balance payment before the delivery

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23