WPC Profile Machine/Wood Plastic Profile Making Machine for Door and Window Frame/Window ...

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

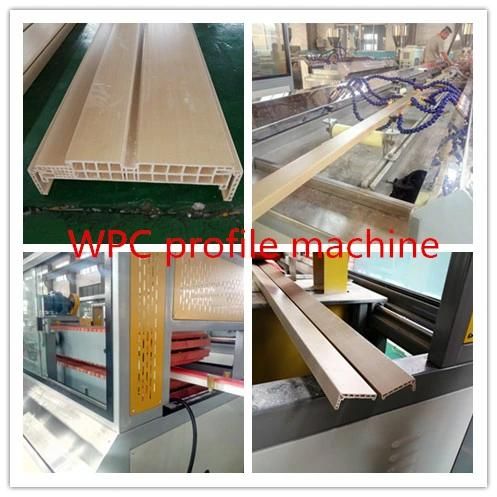

The production flow for WPC project as follows:

1.Wood powder machinery(To get drying wood powder):Wood chipper/Wood powder making machine/Wood powder drying machine.

2.WPC mixer(To mix wood powder,plastic and other chemical additives. Get WPC powder)

3.WPC granulating machine(To make WPC powder to WPC pellets)

4.WPC profile making machine(To make different WPC profile by changing the mould).

5.Surface treatment machine(To make surface treatment on the profile).Embossing machine, sanding and brushing machine etc.

6.Recycled machine(To recycle bad products). Plastic crusher.

Company Information

Qingdao Tongsan PLastic Machinery Co.,LTD

Qingdao Tongsan Plastic Machinery Co., LTD is a professional plastic extrusion machines manufacturer which stands by the Jiaozhou Bay. Converged with the national first-class scientific talests, our company is engaged in the study of new- type plastic machines and the conversion of international high-and -new technology. Cooperating with scientific research instifutions and institutions of higher education , we are converting the newest scientific payoffs at top speed. We will supply you the high-performance and high-tech plastic machines, Hollow sheet machine, Corrugated pipe machine, PVC and WPC foam board making machine.

Packaging & Shipping

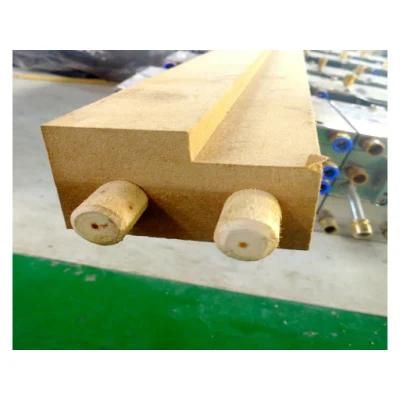

Fastening of fixed Steel Wire with plastic Film wound Wood Block

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

We look forward to have the opportunity to work together with you in the future.

Alan Jia

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23