Shanghai Genyond Meat Vacuum Tumbler

Jiangyin Yiran International Trading Co., Ltd. / 2022-07-05

- Power Source:Electric

- Process:Tumbler

- Automatic Grade:Automatic

- Type:Vacuum Tumbler

- Voltage:380V

- Customized:Customized

=== Base Info ===

- Transport Package:Wood

- Specification:0.3

- Trademark:genyond

- Origin:China

- Production Capacity:50000

=== Description ===

Basic Info.

Transport Package Wood Specification 0.3 Trademark genyond Origin China Production Capacity 50000Product Description

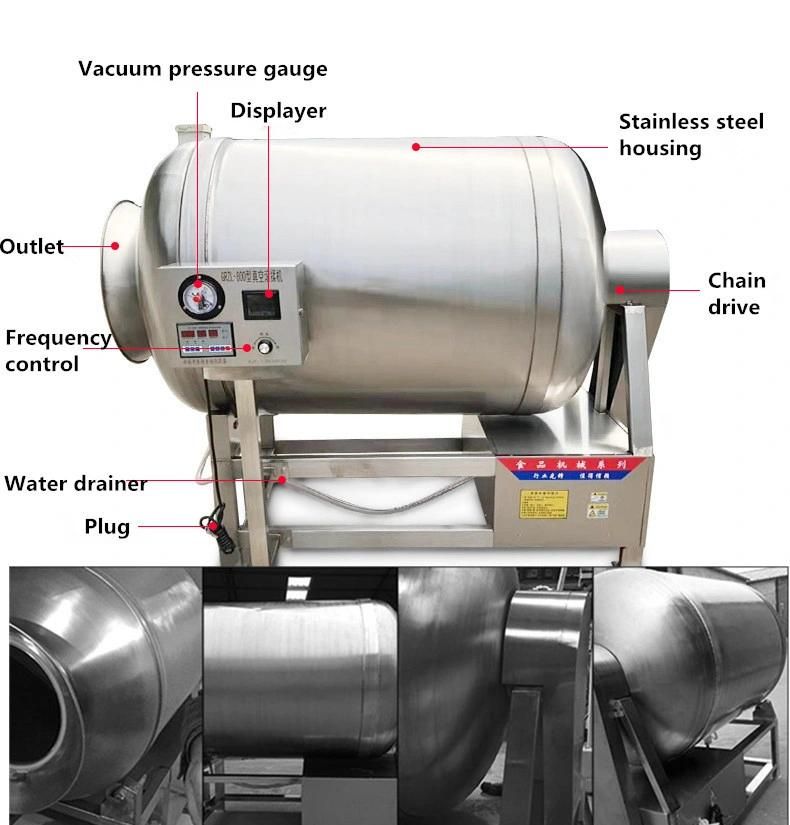

The vacuum tumbler drives the material in the barrel through the roller with the inclined blade inside, so that the raw material is beaten and the raw material is tasted. The vacuum tumbler uses a vacuum pump to draw the inside of the drum into a vacuum state, so that the meat product cells will have osmotic pressure inside and outside the cell membrane due to the difference in pressure, and the cells will automatically pick up the pickling liquid like breathing. The vacuum pickling machine can reduce the curing time of the product and shorten the production cycle of the product.

Working principle of the tumbler:

The tumbler adopts variable frequency stepless speed regulation, and the speed range is 3-12 rpm (you can choose 1-4 rpm low speed function). Start smoothly, reduce the impact of the machine when starting, and extend the life of the equipment. Specially configured auxiliary vacuum suction pipe. With (optional) PLC and touch screen control, the total working time can be divided into up to six process cycles, each process cycle is divided into two steps, each time setting the time, speed, vacuum state, and steering separately. Meet the processing requirements of diverse products. High standard hygiene design. The whole machine adopts SUS304 high-quality stainless steel material; the inside of the rolling bucket is finely polished, there is no sanitary dead angle, and the discharge position can be completely drained. Optional "V-shaped" and "single-piece" blades with different rolling strengths to suit different products.

Advantages:

First: the environment of rolling and pickling is a vacuum state, inhibiting the growth and reproduction of microorganisms, and reducing the factors of food oxidation or corruption.

The second is to make the product roll under vacuum, which will make the physical volume of the product get large and soft. Make the product taste better.

Third: Rolling the product under vacuum will reduce the heat generated when the product is rubbed or beaten.

Fourth: the physical structure of the product under vacuum is bulky, which is beneficial to the absorption of the auxiliary materials, thereby improving the water retention of the product, maintaining the tenderness of the meat and improving the yield.

Main model & parameters:

| Model | Capacity (kg/batch) | Volume (L) | Power (kw) | Speed (r/min) | Dimension (mm) | Weight (kg) |

| GR-60 | 20 | 60 | 0.95 | 16 | 829*400*782 | ≈90 |

| GR-200 | 60 | 200 | 1.5 | 15/frequency control | 1270*620*1100 | ≈200 |

| GR-400 | 100 | 400 | 2.2 | frequency control | 1280*820*1380 | ≈270 |

| GR-600 | 200 | 600 | 2.2 | frequency control | 1330*1020*1573 | ≈330 |

| GR-800 | 300 | 800 | 2.2 | frequency control | 1490*1020*1573 | ≈400 |

| GR-1000 | 500 | 1000 | 3 | frequency control | 1760*1020*1573 | ≈480 |

| GR-1500 | 600 | 1500 | 3.8 | frequency control | 2000*1120*1680 | ≈580 |

| GR-2000 | 800 | 2000 | 4.8 | frequency control | 2390*1230*1836 | ≈960 |

| GR-2800 | 1000 | 2800 | 7 | frequency control | 2560*1430*2100 | ≈1160 |

| GR-3600 | 1500 | 3600 | 10.3 | frequency control | 2830*1540*2220 | ≈1500 |

| GR-4800 | 2000 | 4800 | 11.5 | frequency control | 4000*1650*1950 | ≈2100 |

Inspection and maintenance:

1. Check the lubrication condition of the chain sprocket every two weeks, and timely fill the oil;

2. The first month of the reducer and the oil must be changed every half year (40# oil);

3. The electrical equipment is operated once every six months;

4. The main shaft and the bearing of the roller are replaced once every six months;

5. The sealing ring should be replaced in time after aging;

6. The water in the filter should be drained in time.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23