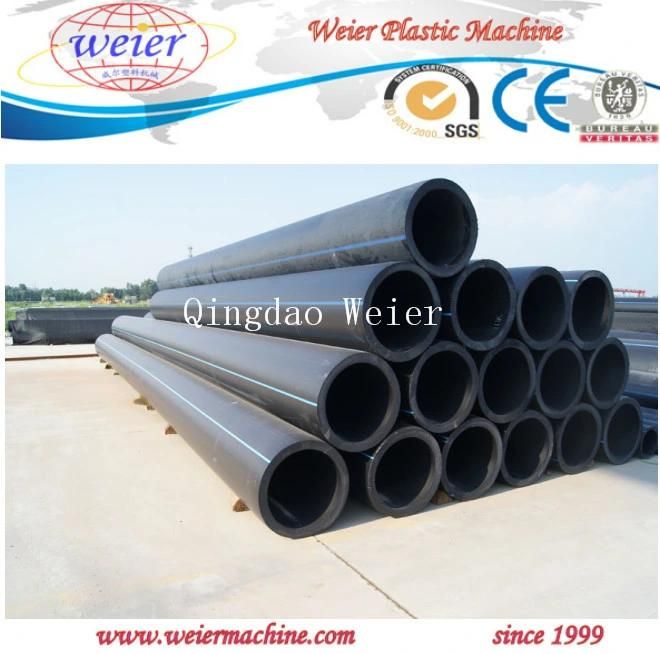

PE HDPE Plastic Pipe Making Machine Extrusion Line (SJ-90/38) with Certification Factory ...

CHINA GTL TOOLS LIMITED / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. sj-120/38 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Power Supply 380V Three Phase Suitable Resin HDPE Max Line Speed 1100kg/H Max Output 20*4*5 Weight 12t Center Height 1000mm Contactor Siemens PLC Omron Inverter Teco Brand Weier Transport Package According to Customers Needs Specification ce iso9001 2008 Trademark WEIER Origin Qingdao, China HS Code 84772090 Production Capacity 89 SetsYearProduct Description

PE Gas/ Water Supply Pipe Plastic Making MachineThe high efficiency extruder with forced cooling system ensures high out-put with high running speed.

Easy to adjust and even extruding

Sizing sleeve with unique notch technique notch technique and water circle cooling to ensure molding precision

Advanced PLC computer and touch screen control system

Failure diagnosis function

Friendly man-machine dialogue function

Temperature control modularization and technology parameter storing function.

2.Summary of PE Gas/ Water Supply Pipe Plastic Making Machine (SJ-120X33)

| NO. | item | parameter |

| 3.2.1 | suitable resin | parameter |

| 3.2.2 | pipe diameter scope | HDPE |

| 3.2.3 | line speed | 200-400mm |

| 3.2.4 | max output | 0.2-2m3 |

| 3.2.5 | outer dimension | 650kg/h |

| 3.2.6 | weight | 59*3*3.5m |

| 3.2.7 | total power | 22T |

| 3.2.8 | used power | 348kw |

| 3.2.9 | air consumption | 243kw |

| 3.2.10 | volume of cycing water | 0.8m3/min,air pressure:0.2-0.7MPA |

| 3.2.11 | needed workshop | 600m2 |

| 3.2.12 | power supply | 380v±10%,50HZ;controlling power supply:220V±10% |

| 3.2.13 | water resource | industral water,inclusionfree,after filtering treatment ,inlet temperature:12-15C°,water pressure:6 bar |

| 3.2.14 | temperature of working conditions | 20± |

3.Equipment list of PE Gas/ Water Supply Pipe Plastic Making Machine

| item | Name | Quantity | |

| 4.1.1 | Single screw plastic extruder | One set | |

| 4.1.2 | Single screw plastic extruder | One set | |

| 4.1.3 | Electric applaince controlling system | One set | |

| 4.1.4 | Mould and diameter-fixed cover | One set | |

| 4.1.5 | Vacuum calibrating device | Two sets | |

| 4.1.6 | Spraying cooling water trough | Three sets | |

| 4.1.7 | Petrail haul-off device | One set | |

| 4.1.8 | Planetary cutting device | One set | |

| 4.1.9 | Discharging table | One set | |

| 4.1.10 | vacuum material-loading device | One set | |

| 4.1.11 | drying device | One set | |

| 4.1.12 | ribbon heat transfer printer | One set | |

| 4.1.13 | Spares parts | One set |

4.Processing flow with our PE Gas/ Water Supply Pipe Plastic Making Machine (SJ-120X33)

Raw material preparation-vacuum feeding machine -hopper dryer- single screw extruder -color code extruder-mould and calibrator vacuum forming machine -cooling tank -haul-off machine -cutting machine- discharging rack.

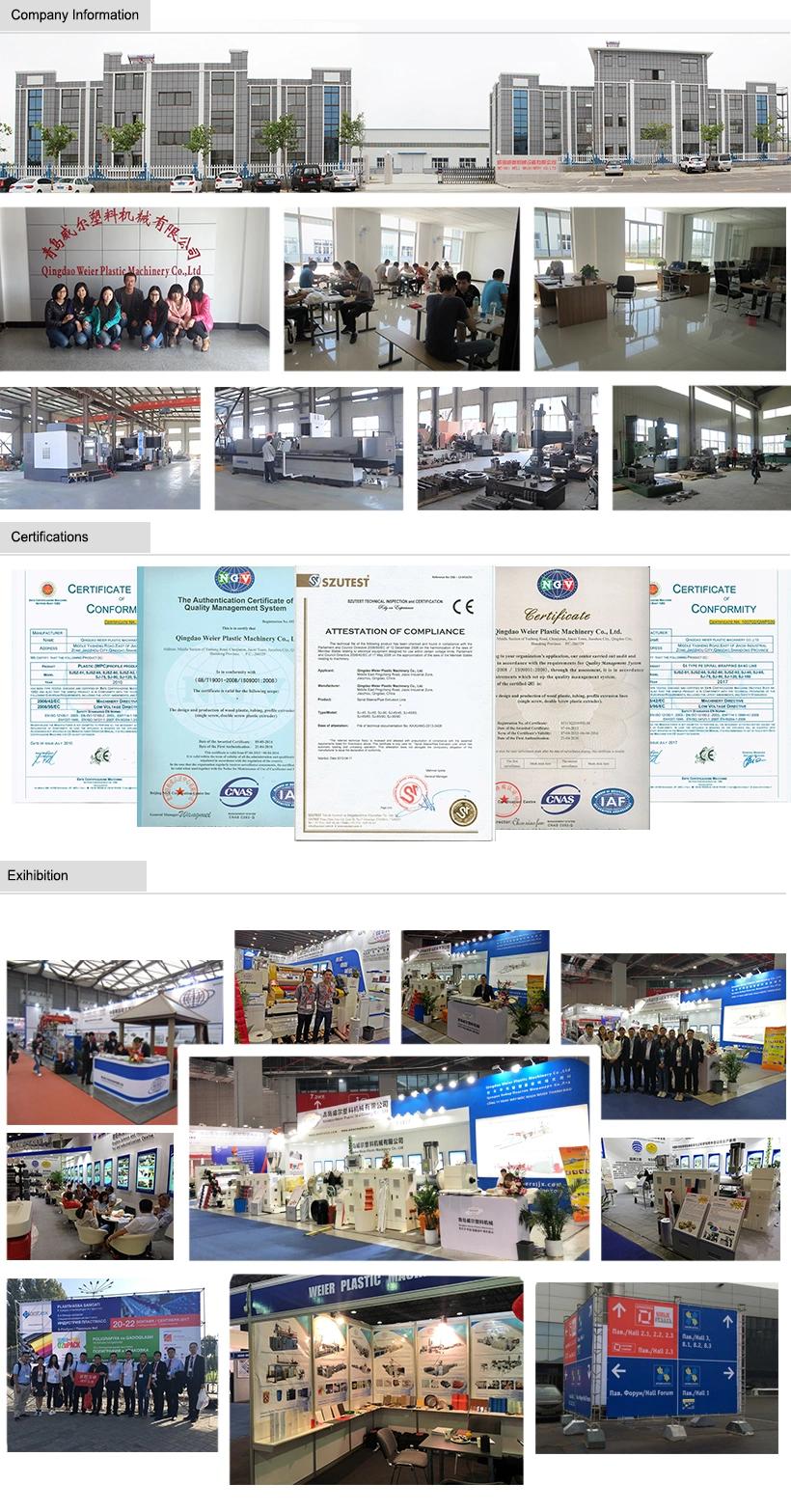

Qingdao Weier Plastic Machinery Co., LTD (click here for company video and other information) is a professional manufacturer who is devoted to macromolecule science and plastic machinery and equipment, is the director member of WPC (Plastic &Wood Production Council of Chinese Plastic Community), now we are Plastic Engineering Technology Research Institute of Qingdao Science and Technology University Test and Industrialization center.

We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement and have a strong association with many macromolecule and chemical majors of many universities. At the same time we bring in and absorb advanced processing engineering of foreign plastic machines to realize chain service of technique and machines.

We have supplier assessment report for alibaba's 7 year's gold member with high fame from both home and abroad.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23