Full Automatic Linear Type Piston Food Sauce Beverage Lubricant Engine Edible Oil Filling ...

Wuhan Haokelao Packaging Technology Co., Ltd. / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:220V

- Composition:Filling Machine

- MOQ:1 Set

- OEM:Yes

=== Base Info ===

- Model NO.:GP5600

- Capacity:1200-5000bph Depends on How Many Nozzles

- Weight:1000 Kg

- Buffer Tank:with Level Controls

- Driven Type:Electric

- Certificate:Ce & ISO

- Filling Material:Edible Oil Filling Machine

- Air Consumption:0.8 ~ 1.8 M3,Min

- Transport Package:Plywood Case

- Specification:2000*2200*1950mm

- Trademark:Grepack

- Origin:China

- Production Capacity:20 Set Per Month

=== Description ===

Model

Unit

GP5600

Nozzle Number

PCS

4

6

8

10

12

Production capacity

Barrel/h

720-1300

1200-1900

1400-2600

1600-3200

1800-4000

Quantitative error

%

≤0.5%

Source voltage

V

Three-phase four-wire system AC220V 380V ±10%

Consumed power

KW

2.5

2.5

2.8

3.5

4

Gas supply pressure

MPA

0.55-0.8

Air consumption

M3/min

0.8

1

1.2

1.2

1.8

Main characteristics :

1. One year Guarantee.

2. One year free spare parts will be shipped with the machine.

3. We can help install the production line or machine , the customer need to provide the room, board, round tickets and pay $80/day to our Technician.

4. The filling range is easy to adjusted on monitor , and easy to adjust according to different bottle size

5. Accuracy: ± 0.3%. (for 1000ml).

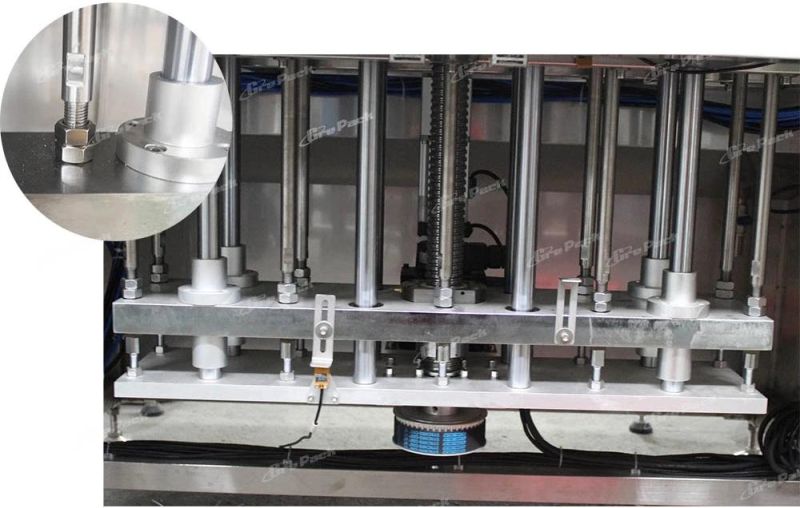

6. Main servo motor control.

7. CE approved and production comply with GMP standard .

8. All the driven bearings are with high quality imported from Germany

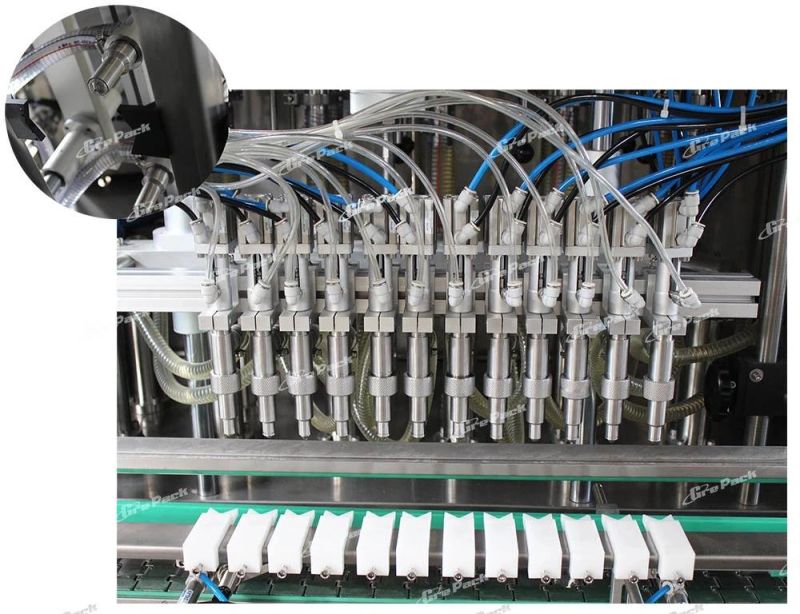

9. All the valve, filling nozzles , pistion connnection are with clamps structure , easy to remove and clean

10. can be design with CIP connection function with CIP cleaning system

11. The buffer tanks with level control system

12. Machine with mature alarm system for safe operation.

- Equipment with bottle clamping device, ensure bottle in right filling position and avoid bottle dumping when filling.

- Filling nozzles are with suck-back to function avoid leakage suitable for material like oil, syrup, and some other material with good fluidity.

- Prefect inspect system with sensors and two block cylinder. Ensure no bottle no filling no enough bottle come to right position no filling.

Servo motor controls the position filling

Filling speed is faster and more stable

Easy to adjust the filling ranger on monitor

Also with minite adjust for filling range by screw

Oil use three way valve

- Connecting among tank, rotate valve, position tank all with fast remove clamps.

- Adopt oil use tree way valve, which is suitable for oil, water and material with good fluidity, the valve is special designed for oil without leakage, ensure high accuracy.

Shanghai Grepack Packing Macinery Co.,ltd, founded in 2002, is a professional manufacturer of package machinery. After our hard work, the products has export to more than 70 countries and help thousands customers to solve there's problem.

Our main product Glass jar filling machine (include bottle turning table, washing machine, filling machine, labeling machine, capping machine, sealing machine, containing system, robot palletizer) and Pouch packing line (form filling seal doypack & flat bag packing machine, premade pouch packing machine, filling device for powder, liquid, granules, weight checker, metal detector, cartoning system, robot palletizer) are get good reputation from our customer from all over the world. All products are Approved CE & ISO standard.

Now we have enough professional researchers who have more than 10 years experience, and about 100 workers, professional export team to service for you. Hope the good relationship.

Warranty

Warranty: 12 month and 12 months free spare parts

Out of warranty time: we still supply board and favorable technical support and after service of life.

Installation

Before shipment, machine will be tested by our technicians to make sure the can work well.

Our technicians will be sent to user's factory to install the machine and train works if need. ( the buyer just need pay for the technician's tickets, meals accommodation and salary)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23