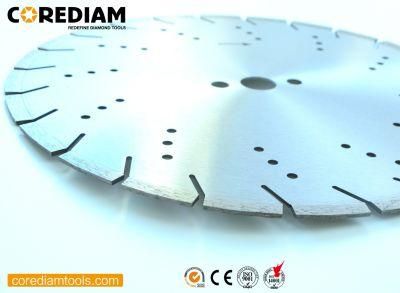

Superior Fast Cutting Laser Welded Concrete Saw Blade in 450mm

Pinghu Kaixin Plastic Industry Co., Ltd. / 2022-06-27

- Blade Type:Turbo Segment

- Manufacturing Process:Laser Welded

- Application:Concrete

- Application Equipment:Handheld Power Saw, Walk Behind Saw, Masonry Saw

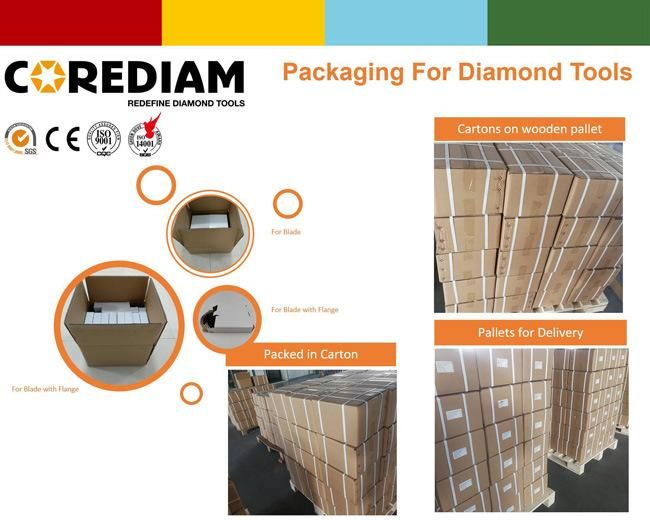

- Transport Package:Carton, Pallet

- Specification:450x10x25.4mm

=== Base Info ===

- Model NO.:CCLD

- Trademark:Corediam

- Origin:China

- HS Code:82023910

- Production Capacity:50PCS,Day

=== Description ===

Basic Info.

Model NO. CCLD Trademark Corediam Origin China HS Code 82023910 Production Capacity 50PCS/DayProduct Description

1. Product Introduction

This blade is laser welded by full-automatic laser welding production line, designed for universally dry and wet cutting for concrete, cured concrete, reinforced concrete, masonry, asphalt, green concrete and other kinds of construction materials. Narrow U tilted slots are suitable for cooling and noise reduction. It can be installed on the handheld circular saw, angle grinder, table saw. The diameter is 450mm, the segment height is 10mm.

Features of Laser Welded Turbo Saw Blade for General Purpose1). Specially designed tilted slots segments improve cooling of blades and provide better removal of debris.

2). Due to laser welding technology, it can offer fast, smooth, safe cutting during your projects, having high performance/price ratio.

3). Maximizing the value with good performance.

4). Superior fast cutting

5). Sandwich structure turbo segment

6). Different grade to choose

2. Application

These blades are used for cutting green concrete,asphalt-concrete and other abrasive materials with superior efficiency.

3. Specification

| Item No. | Diameter | Segment Height | Segment Width | Arbor |

| CCLD30010 | 300mm | 10mm | 3.2mm | 20/25.4mm |

| CCLD35010 | 350mm | 10mm | 3.2mm | 25.4mm |

| CCLD40010 | 400mm | 10mm | 3.2mm | 25.4mm |

| CCLD45010 | 450mm | 10mm | 3.6mm | 25.4mm |

| CCLD50010 | 500mm | 10mm | 3.6mm | 25.4mm |

OEM service offered.

4. Delivery time

Our leading time will be about 2 weeks for the batch order.

5. Laser Welded Diamond Saw Blade Manufacturing Technique

Raw material→ powder mixing → Steel core process → cold press → segment sintering → welding → surface treatment → package → dispatch

6. Corediam manufacturing facility

7. Corediam Introduction

Corediam Tools Co., Ltd., as a high-tech enterprise, concentrates on researching & developing manufacturing and marketing diamond tools industry. We have the most extensive, innovative and powerful range of diamond tools for construction, stone and DIY markets. Corediam strives to be the leading professional supplier in the world through technology innovation.

8.Packing and delivery.

9. Quality control process

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23