Mini Parboiled Rice Machine Agricultural Griding Complete Rice Milling Processing Machine

Shenzhen Xinhui Plastic Products Co., Ltd. / 2022-07-04

- Customized:Customized

- Application:Grain Rice Paddy

- Processing Material:Agronomic Products, Natural Ingredients, Rice Paddy

- Warranty:1 Year

- After-sales Service:Video Technical Support, Online Support

- Certification:CE, MET, CSA, CE ISO

=== Base Info ===

- Local Service Location:None

- Showroom Location:None

- Key Selling Points:Flexible Manufacturing

- Color:Buhler Green and White

- Function:Removing Shell

- Type:Rice Mill Production Line

- Advantages:High Productivity& Low Price

- Price:Negotiable

- Features:Easy Operation& Convenient Maintance

- Rice Milling Rate:68-72%

- Applicable Industries:Machinery Repair Shops, Manufacturing Plant, Food

- Automatic Grade:Automatic

- Power Source:Electric

- Warranty of Core Components:1 Year

- Name:Rice Milling Machine

- Usage:Electric Rice Milling

- Transport Package:Export Packaging

- Trademark:COYO

- Origin:China

- Production Capacity:50000PCS,Year

=== Description ===

Basic Info.

Power Source Electric Automatic Grade Automatic Applicable Industries Machinery Repair Shops, Manufacturing Plant, Food Rice Milling Rate 68-72% Features Easy Operation& Convenient Maintance Price Negotiable Advantages High Productivity& Low Price Type Rice Mill Production Line Function Removing Shell Color Buhler Green and White Key Selling Points Flexible Manufacturing Showroom Location None Local Service Location None Warranty of Core Components 1 Year Name Rice Milling Machine Usage Electric Rice Milling Transport Package Export Packaging Trademark COYO Origin China Production Capacity 50000PCS/YearProduct Description

Modern grain processing needs mechanized production!

Our company have professional solution of paddy projects with the capacity range 4tpd-1000tpd!

advanced technology!

uniform output!

excellent performance!

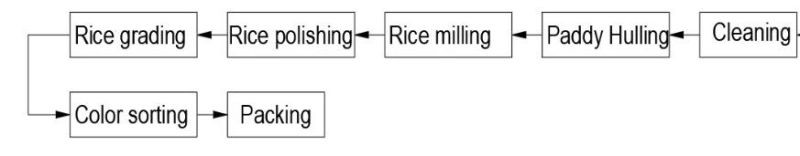

Production Process Of Parboiled Rice

Production Process

Cleaning

In the cleaning process, not only the impurities such as big impurity, light impurity and side impurity should be removed, but also the heavy rice and light rice should be separated preliminarily.

Hulling

After rice cleaning, the rice husk is removed from the surface of rice and separated from the brown rice. This is mainly used in the rice huller, which mainly uses two rubber rollers rotating at different speeds to generate the rubbing force to make the rice hulled. After that, the lighter rice husk is blown away by air separation, and the second heavy brown rice continues to enter the next process.

Milling

The surface of brown rice is called aleurone layer or rice bran layer, which has poor edible and sensory properties, and is not conducive to the storage of finished rice. Therefore, it is necessary to use a white rice machine (rice polisher/rice whitener)to remove the rice bran layer. The main principle is to use the pressure brought by high-speed rotation to make the brown rice rub against the sand roller in the rice milling room, thus scraping the aleurone layer. Because the rice bran layer is more closely combined with endosperm, the grains are hard, and the rice bran is easy to rub out oil, which makes the rice grains slip off and block the sieve holes. Therefore, it is necessary to select the appropriate machine to ensure the smooth operation of the whole process

Polisher

griding and color sorting

After the preliminary grading of rice, grading equipment should also be set up. Use the thickness grader to grade, and use the difference of raw materials in granularity to remove the worm eaten grain, diseased grain, damaged grain, hulled or semi hulled grain and overlong and thick grain in the original grain, so as to ensure that the color of finished rice is uniform and improve its sensory quality

Packing

Finally, the finished rice will be packaged in 2kg, 5kg, 10kg, or other specifications you need, and you can enter the supply link of the shopping mall. We hope that your rice can appear in the best booth and let consumers love it!

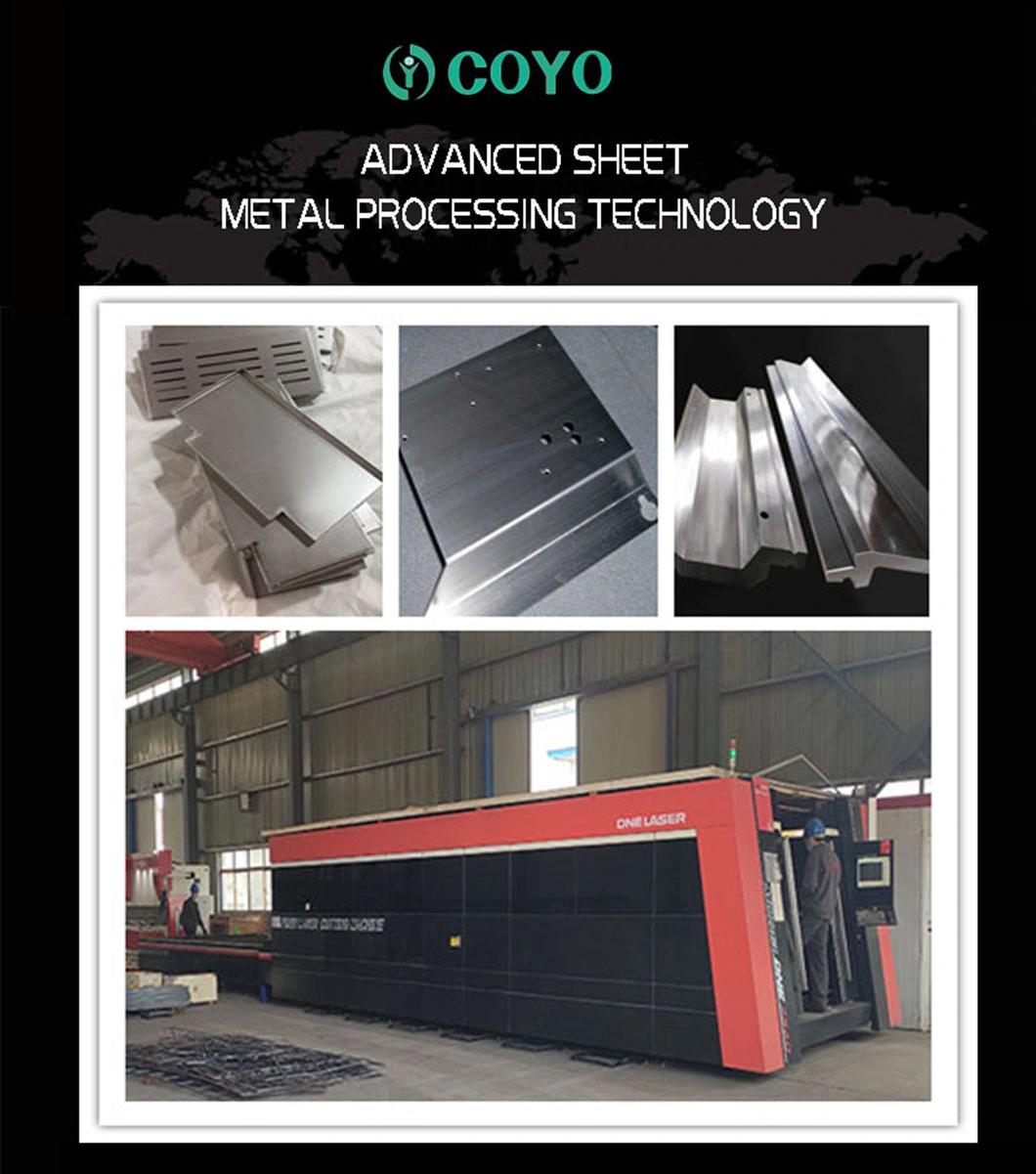

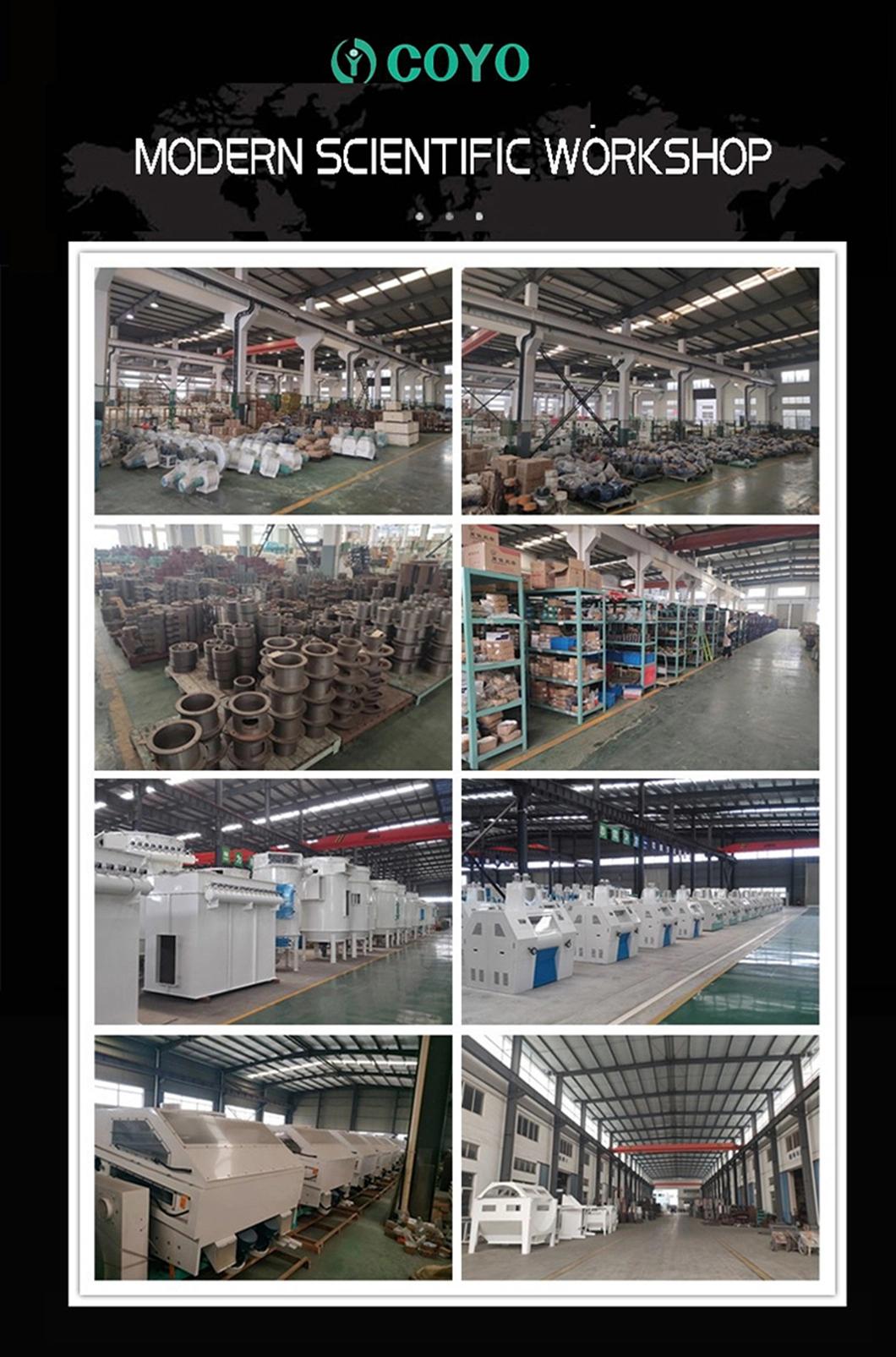

About us

Yangzhou coyotech machinery Co., ltd, is a professional production enterprise of grain machinery, with a production and engineering history of more than 40 years. We are a leading export company in China, who dealing with rice, flour, oil and other coarse cereals processing solution on turnkey basis, It is a professional research, development, design, engineering, sales & service private high-tech enterprises. Our products are all popular in China and aboard, have already exported to more than 20 countries and regions of South-East Asia, South Asia, Africa and South America.

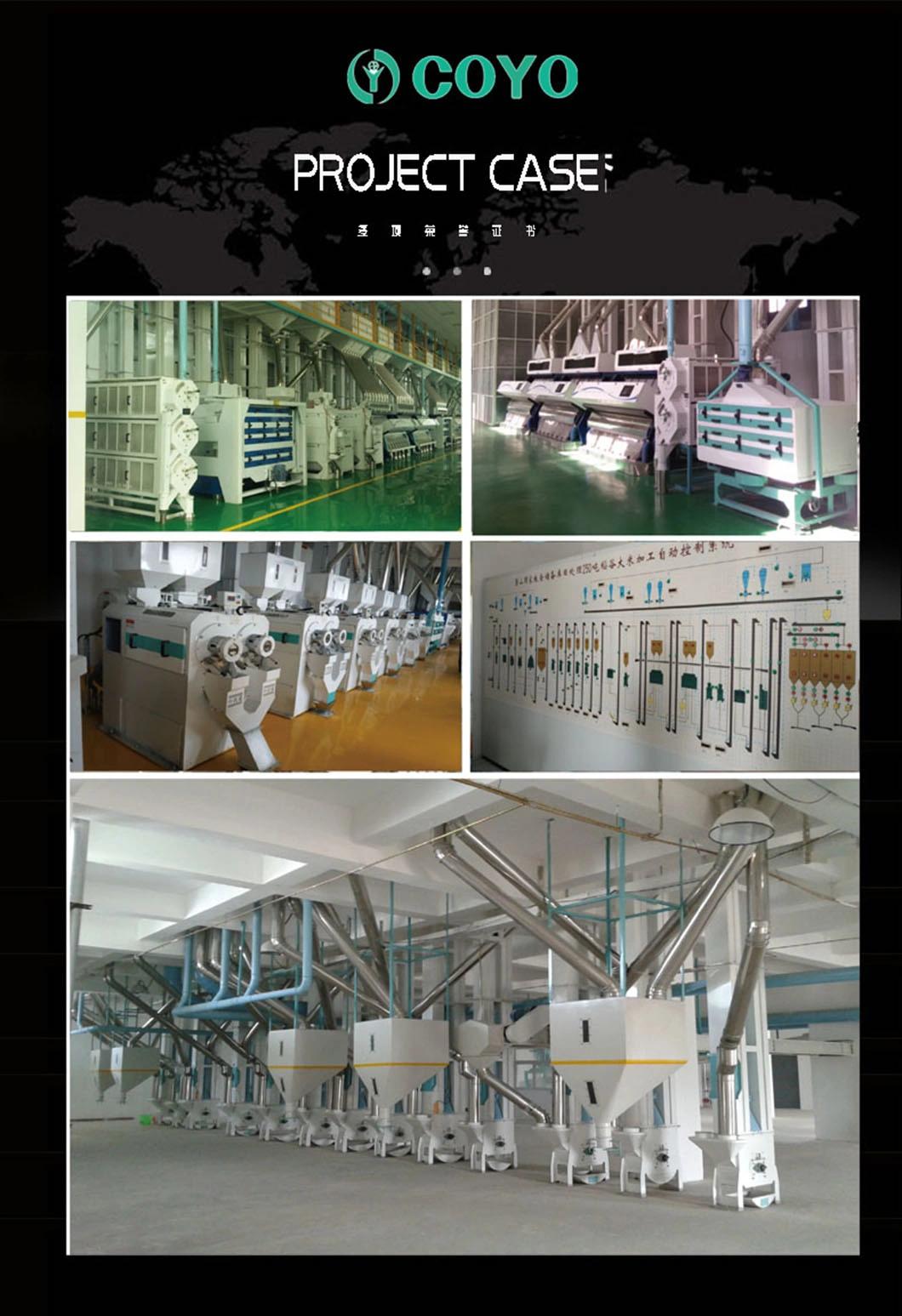

Some Of Our Cases

Packing And Delivery

For safety transportation purpose, we use standard exporting packing for all the machines. Packing method such as wood box/tray, steel box/tray etc, to ensure the machine will be reached to you safely.

Our Service

Pre-sale service

Technical Advisory Services, Our broad product range make us able to offer our customers flexible, efficient and reliable equipment configurations or complete solutions for different requirements and budgets.

Sales service

1. Reliable delivery time.

2. Strict production quality control.

3. User manuals and spare parts are provided free of charge.

After sales service

1. Quick technical guidance for construction, installation and commissioning.

2. The necessary training for routine maintenance on site.

3. A period 12 month warranty.

In addition to wearing parts, we provide a one-year warranty on the whole machine, and provide 24-hour online service for spare parts at competitive prices.

FAQ

1. What screen size you will use on this machine?

We will design the screen type and hole size as per your application, to make sure the best performance.

2. Before testing this machine, what should be checked?

1) Ensure that all safety components for lifting and transport are removed.

2) Check for any remaining tools, bolts, nuts, iron filings or other debris in the equipment and clean them.

3) Make sure that the stone screen is smooth, the screen hole is not blocked, and the installation direction is correct.

3. what is the installation requirement of this machine?

The foundation of the machine should be with sufficient strength to support the weight of the machine.

There should be enough space around the machine for maintenance and inspection.

4. How do you pack this machine for exporting?

We will provide packing which is suitable for the agreed means of transportation and for the foreseeable conditions of storage at the destination.

5. What is the warranty for your machine?

If any defect or non-conformity arising from faulty design, materials, we shall eliminate defects or replace machine.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23