Plastic Barrel/Plastic Film/Plastic Bottles/Plastic Jar/Plastic Basket Twin Screw Shredder

Dongguan Yize Precision Cutting Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

fixed blades

(kg)

(mm)

(kg)

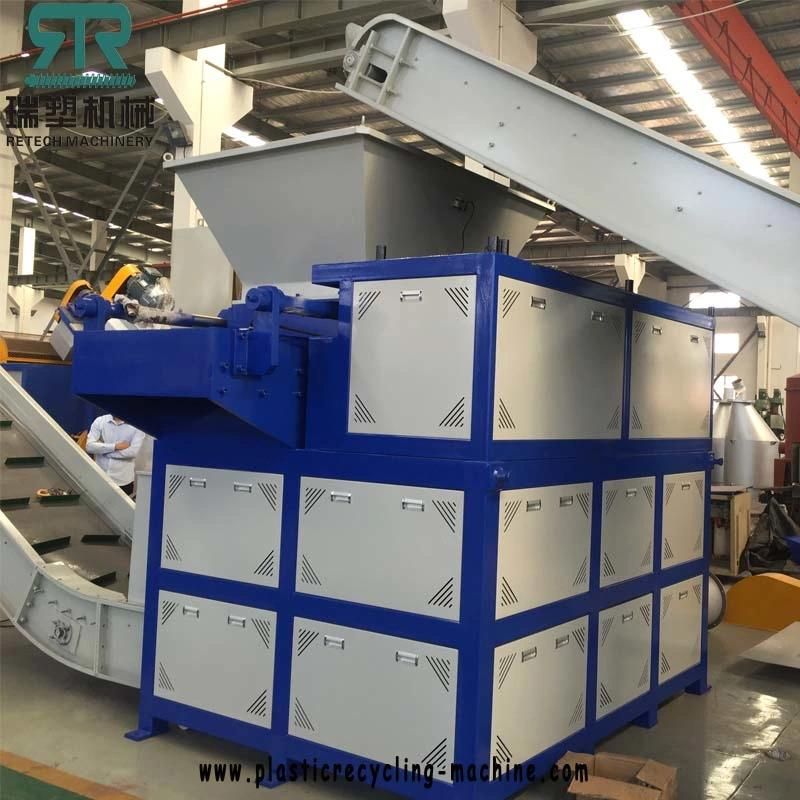

2. Double Shaft Shredder

Application:

The double shaft shredder is mainly used for hard material, such as barrel, basket, panel material, wood, car tires and even big bale film etc…..

Main characters:

1. The shredding cabinet of double shaft shredder is made of special thickness steel panel with precision machining. It is fixed by big angle hexagonal bolts and with strong inlet hopper. All these is to ensure the big and heavy material can be put directly into the shredding cabinets

2. The rotating blades of double shaft shredder are with special designed to the thickness, shape and arranging series which ensure it is strong cutting ability, sharpening cutting edge and then make it working high efficiently.

3. Low speed running, low noise and less powder flying of double shaft shredder.

4. The blades of double shaft shredder are made of special alloy steel, strong and long time working.

5. The electric system of double shaft shredder is controlled by PLC, which make the shaft can rotate in positive direction, reversal direction and stop, then to protect the machines running safely.

Model:

4. Four Shaft Shredder

Application:

1. Bucket products: PE bucket, metal drum, paint bucket, intermediate -bulk container (IBC) and dustbin

2. Wastes: household waste, medical waste, kitchen waste, industrial waste, park waste

3. Plastic products: PE bottle, PE frame, PE block, PE can

4. Metal products: aluminum profile, oil filter, car shell, pop-top can, metal can

5. Paper: newspaper, card paper, corrugated paper, copy paper

6. Electronic appliances: refrigerator, circuit board, laptop shell, TV set shell, CD disk

7. Glass

Main characters:

Four shaft shredder is heavy-duty machine. They have advantages in standardization and modularization design, high interchangeability for their components. Their blades are made of special alloy steel with high strength, strong anti-wear and reparability. The drive part takes advantage of 4 motors, heavy planet gear boxes to make main shafts rotate at different speeds. The electric part takes advantage of PLC program and touch screen control with video monitor system and the automatic detecting overload protection function. They have low rotation speed, big torque and low noise characters. So they have won customers' trust and got popularity in the shredding process in the recycle industry They fit for shredding large and hard objects such as car body, solid industrial waste ,medical waste, e-waste, PE pail, PE frame, PE bottle, metal can, metal pail, intertexture bag, fridge, electric circuit board, paper box, wood and so on.

5. Package Shredder Crusher Machine

6. Pipe Shredder/Granulator

Order flowing process:

Customer requirements →Scheme designed →confirmed by customers →order fixed →manufacturing →trial running in our factory →confirmed by customers →shipped →engineer available overseas →whole life after sales services

Contacts:

RETECH Machinery is an experienced and professional manufacturing for series plastic washing recycling machine/ plastic granulating recycling machine including ET bottle recycling machines, PE PP film recycling machines, plastic PE PP PS ABS PET PC PVC LD HD LLD BOPP granulating line, water treatment for the waste water from washing line, and auxiliary equipment for plastic recycling....

If you are interesting more details of our products, please contact with us no hesitation!

plasticmachine.en.made-in-china.com

Mob: 0086-152-50376025

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23