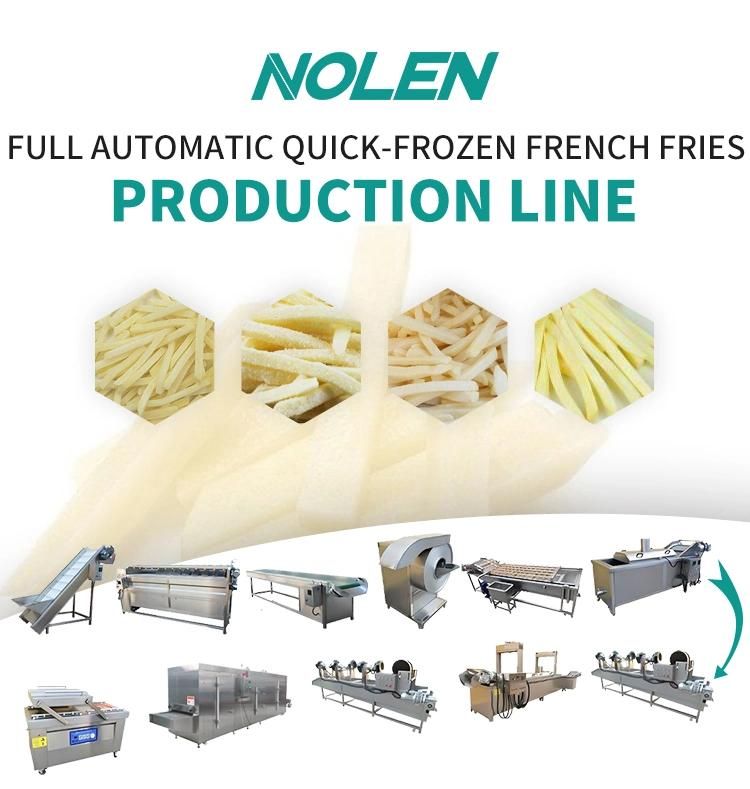

Automatic Frozen French Fries Making Producing Line

AIRMAX AL CO., LIMITED / 2022-07-05

- Type:Frozen French

- Voltage:380V

- Power:1.1KW

- Customized:Customized

- Name:Fresh Frozen French Fries

- Function:Potato Processing ,Frozen.Fryer

=== Base Info ===

- Model NO.:KS1000

- Model:Batch Fryer

- Power(W):36kw

- Weight:900kg

- Capacity:100-2000kg,H

- Dimension(L*W*H):1200*1200*1400mm

- Heating Source:Electric, Gas, Steam, Diesel, Coal

- Material:304 Stainless Steel

- Feature:High Efficiency

- Application Fields:Vegetable Processing Plant, Snack Food Factory, Po

- Output Product Name:Potato Chips, Fries

- Warranty:1.5 Year

- After-Sales Service Provided:Video Technical Support, Engineers Available to Se

- Transport Package:Wooden Case

- Specification:1200*1200*1400mm

- Trademark:KeySong

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:20et,Month

=== Description ===

Basic Info.

Model NO. KS1000 Model Batch Fryer Power(W) 36kw Weight 900kg Capacity 100-2000kg/H Dimension(L*W*H) 1200*1200*1400mm Heating Source Electric, Gas, Steam, Diesel, Coal Material 304 Stainless Steel Feature High Efficiency Application Fields Vegetable Processing Plant, Snack Food Factory, Po Output Product Name Potato Chips, Fries Warranty 1.5 Year After-Sales Service Provided Video Technical Support, Engineers Available to Se Transport Package Wooden Case Specification 1200*1200*1400mm Trademark KeySong Origin Shandong China HS Code 8438800000 Production Capacity 20et/MonthProduct Description

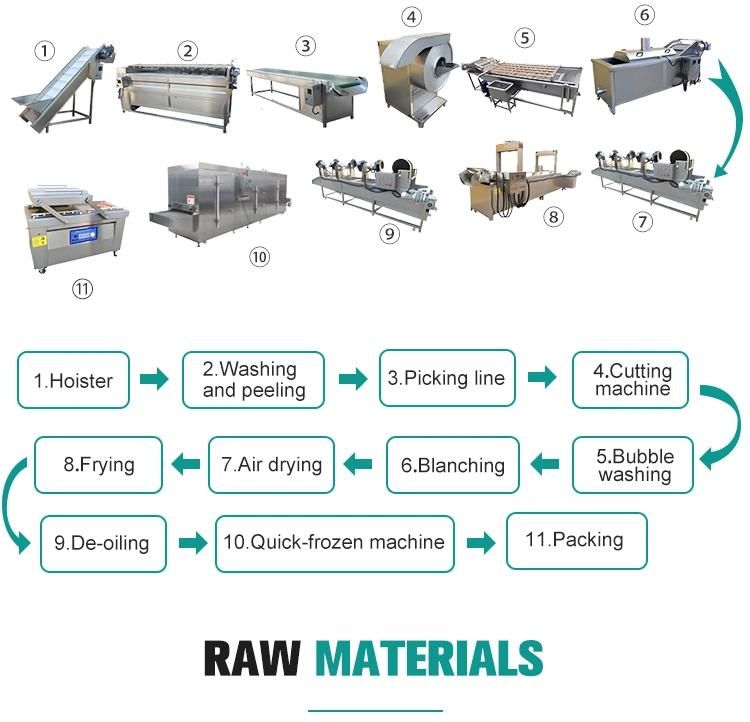

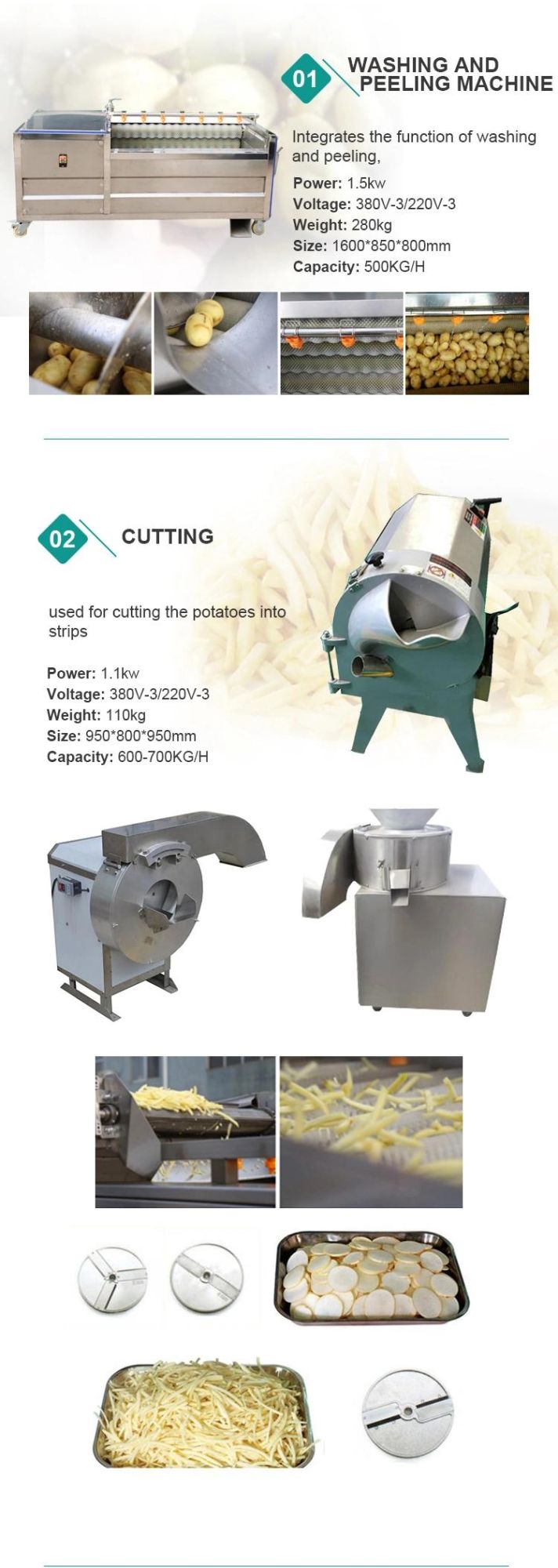

Introduction of complete equipment

Parameter

| NO. | MODEL | MATERIAL | LENGTH | BELT WIDTH(mm) | HEATING METHOD |

| 1 | KS-8500 | SS 304 | 8500mm | 800, 1000, 1200mm | ELECTRIC, GAS |

| 2 | KS-6500 | SS 304 | 6500mm | 600, 800, 1000mm | ELECTRIC, GAS |

| 3 | KS-5500 | SS 304 | 5500mm | 600, 800, 1000mm | ELECTRIC, GAS |

| 4 | KS-4500 | SS 304 | 4500mm | 400, 600, 800mm | ELECTRIC, GAS |

| 5 | KS-3500 | SS 304 | 3500mm | 400, 600, 800mm | ELECTRIC, GAS |

| 6 | KS-2500 | SS 304 | 2500mm | 300, 400, 600mm | ELECTRIC, GAS |

Packaging and shipping:

Every machine is packed with great care and tough material. It is packed with

cling films first and then film bags. At last, it is packed with wooden case which

is reinforced with the iron bar on the top and bottom.With this kind

machine, all our laser machine can protect well during long trip by sea or by

train.We can transport machine by

boat or by training, according to your requirement.

Company Information:

Keysong was founded in 2013. Specializing in producing food machines for

more than 6 years. Since its inception, it is specializing in the manufacture,

research, development, sales and after-sales of food extrusion machine,

puffed food production line, fruit and vegetable washing and drying processing

line.

Our History:

In 2013, Keysong was established, concentrating on manufacturing and selling

extrusion snack production line at home and abroad.

In 2014, Keysong broke traditional breakfast cereal production technology, and

invented new production process.

In 2015, Keysong moved to a new workshop, which covers the area of 5000

square meters. In 2015, we have our agency in India, Nigeria, Thailand,

Morocco and Algeria.

In 2016, Keysong cooperated with Shandong Liwei Microwave equipment,

started researching on food microwave drying technology. In August, 2016,

Keysong build a team, concentrating on researching on the technology of

vegetables and fruits washing, cutting, drying and freezing. And has received

great results till now.

FAQ:

1. How about the documents after shipment?

After shipment, we'll send all original documents to you by DHL/TNT, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

For standard machines, it would be20-30 days; For non-standard machines and customized

machines according to client's specific requirements, it would be 30-45 days.

3. Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW

price, clients need to arrange shipment by themselves or their agents.

4. How is the packing?

Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box

Package with Steel Belt Save space as much as possible for container loading

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23