Single Layer Rotary Die Head PE Film Blowing Machine Youtube Link

Huzhou Gu's Imp. & Exp. Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

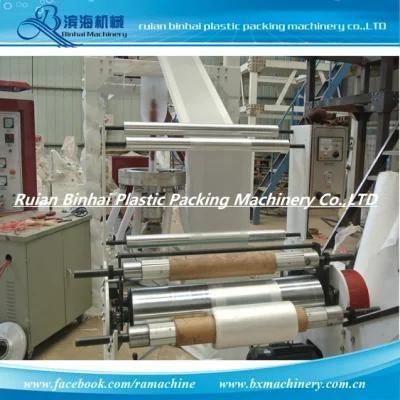

LDPE / HDPE Rotary Die Head Film Blowing Machine

1.certificate: CE

2. high quality with the most competitive price

3.make special accoring to the client requirment

4. Rotary dIe Head. double rewinder

Use:

It is used for blowing the various plastic film of low density polyethylene (LDPE), high density polythylene(HDPE) and linear low density polyethylene(LLDPE) etc. Which are widely used for packing liquid industrial products garment and textile, etc. And printing lamination.

Characteristics:

The cylinder and the screw stems of the extruder are made of high quality alloy steel with optimum hardness and strong corrcsion resistance after ntrogen treat- ment and precision finishing. The auxllary machine has a plat from working table for making operation easy and is equipped with bubble stabillzing ring. Double- rolling and double cutting unit adopts torque motor to motor to keep proper tension and make even and roll-changing easy.

| Model | SJ-50 | SJ-55 | SJ-60 | SJ-65-1 |

| Screw Diameter | 50mm | 55mm | 65mm | 65mm |

| Screw Ratio(L/D) | 28: 1 | 28: 1 | 28: 1 | 28: 1 |

| Screw Speed | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min |

| Power of Main Motor | 11Kw | 15Kw | 22Kw | 22Kw |

| Max Output | 30-35kg | 40-50kg | 55-60kg | 60-70kg |

| Max. Folding Width of Film | 600mm | 800mm | 1000mm | 1200mm |

| Single-sided Thickness of Film | 0.008-10mm | 0.008-10mm | 0.008-10mm | 0.008-10mm |

| Total Power | 22Kw | 26Kw | 30Kw | 36Kw |

| Weight of Machine | 2T | 2.3T | 2.6T | 3T |

| Overall Dimensions | 4000 x 1800 x 4600mm | 4200 x 2000 x 4900mm | 4600 x 2300 x 5600mm | 4800 x 2500 x 5800mm |

standard configure:

| 9 | Barrel and screw material: 38 chrome-molybdenum aluminum, nitrogen treated |

| 10 | Rotary die device: Continuous 360 degree rotation |

| 11 | Gear box: water cooling reducer, hard tooth surface |

| 13 | Double winder ( with banana roller, cold knifes for cutting edges of the film and middle of film 3pcs ) |

| 14 | counter of metric (Length Counter, speed display) |

| 15 | Main motor: WN brand motor CHINESE BRAND INVERETER (optional Yasyawa etc. ) |

| 16 | Heating ring: cast aluminum |

| 18 | Air compressor |

| 19 | winder motor: torque motor |

| 20 | Embossing roller |

| 21 | Gusset device |

| 22 | UP AND DOWN DEVICE |

| 23 | Waste collection device |

Making Plastic Bags need 2-3 sets machine , If don't need color, 2 sets .

First Machine : PE Film Blowing Machine :

---- What's your products size

---- Products need print not

---- Film need slit not

---- Single Layer, Two Layer or Three Layer ?

Second Machine : Flexo Printing Machine : ( If your bags is blank , not need this machine ):

we also have Printing machine online with Film blowing machine .

---- What's size of your Raw material Film roller

---- How many colors you want ?

---- Speed ? 50m/min , 80 m/min or 90 mpm .

Third Machine : Bag Making Machine :

( we have many different kind machines to make different bags )

---- What kind bags you want to produce ? better show us pictures.

---- What's your Bag size.

---- Have printed Logo Not .

shipping & Package

The End , thanks for your reading .

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23