200kg Chocolate Refining Paste Making Mill Chocolate Ball Mill Qmj250

SHANTOU DAFU PLASTIC PRODUCTS FACTORY CO., LTD. / 2022-07-05

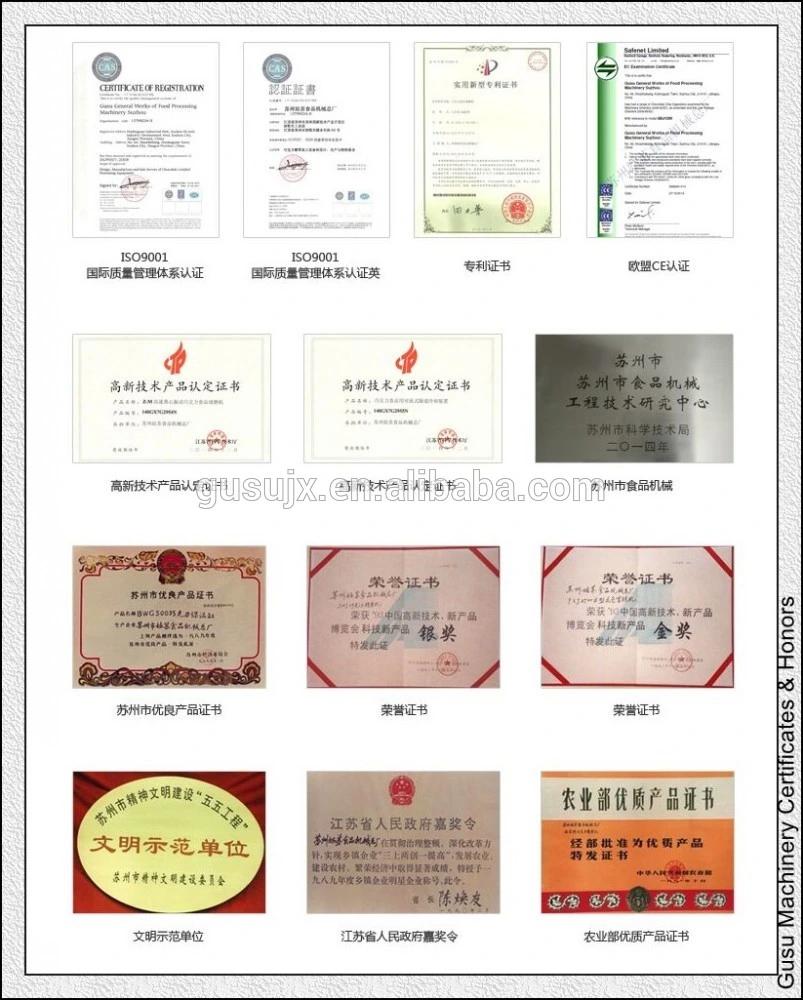

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Grinding

- Automatic Grade:Automatic

- Application:Candy, Chocolate

- Customized:Customized

=== Base Info ===

- Power(W):1.5kw

- Model NO.:QMJ250

- Spindle Speed:250-500 R,Min

- Input/Output Pump:0.75kw*2

- Weight:1000kg

- Warranty:1 Year

- Cooled Water:1500 Kg,H

- Avg. Process:150-250kg

- Circulation Water:3kw*2

- Dimension(L*W:1240*960*1733mm

- Main Motor:7.5kw*2

- Transport Package:Wooden Box

- Specification:124*960*1733

- Trademark:GUSU

- Origin:China

- HS Code:8438200000

- Production Capacity:500 Unit,Units Per Month for Ball Mill Machine

=== Description ===

Basic Info.

Model NO. QMJ250 Power(W) 1.5kw Spindle Speed 250-500 R/Min Input/Output Pump 0.75kw*2 Weight 1000kg Warranty 1 Year Cooled Water 1500 Kg/H Avg. Process 150-250kg Circulation Water 3kw*2 Dimension(L*W 1240*960*1733mm Main Motor 7.5kw*2 Transport Package Wooden Box Specification 124*960*1733 Trademark GUSU Origin China HS Code 8438200000 Production Capacity 500 Unit/Units Per Month for Ball Mill MachineProduct Description

Ball Mill

1.Product DescriptionThe chocolate ball mill is mainly used to finely grind the chocolate slurry. The chocolate slurry is ground through the friction and collision between the steel ball and the slurry. It can be used as independent refining equipment, and can also be used in conjunction with a conche to increase the output and shorten the refining time.

1)Excellent product fineness and homogeneity

2)Extremely low energy consumption

3)Consistent product quality

4)Extremely low wear and virtually no maintenance costs

5)Full automatic, easy to operate

2.Technical Parameters

| Model | QMJ250 | QMJ500 |

| Main Motor(KW) | 15KW | 30KW |

| Spindle Speed(r/min) | 250-500 | 280-630 |

| Grinding Medium(kg) | 200 | 400 |

| Avg. Process Ability(kg) | 150-250 | 500kg/h |

| Cooling Water(kg/h) | 1500(15-20ºC) | 2000(15-20ºC) |

| Input/output Pump(KW) | 1.5 | 3.0 |

| Overall Size(mm) | 1240*960*1733 | 2320*1070*2385 |

Fine Refining of

- Chocolate

- Compounds

- Creams

- Daily Application Chemical Materials

- Other Low Fat Masses

-Consistent product quality.

-Simple, fully automatic operation.

-Requires a minimal amount of space, no foundations required.

-Low energy consumption.

-Very low maintenance costs.

-Extremely low wear.

-Very flexible in terms of recipes and product composition.

-Fast payback time.

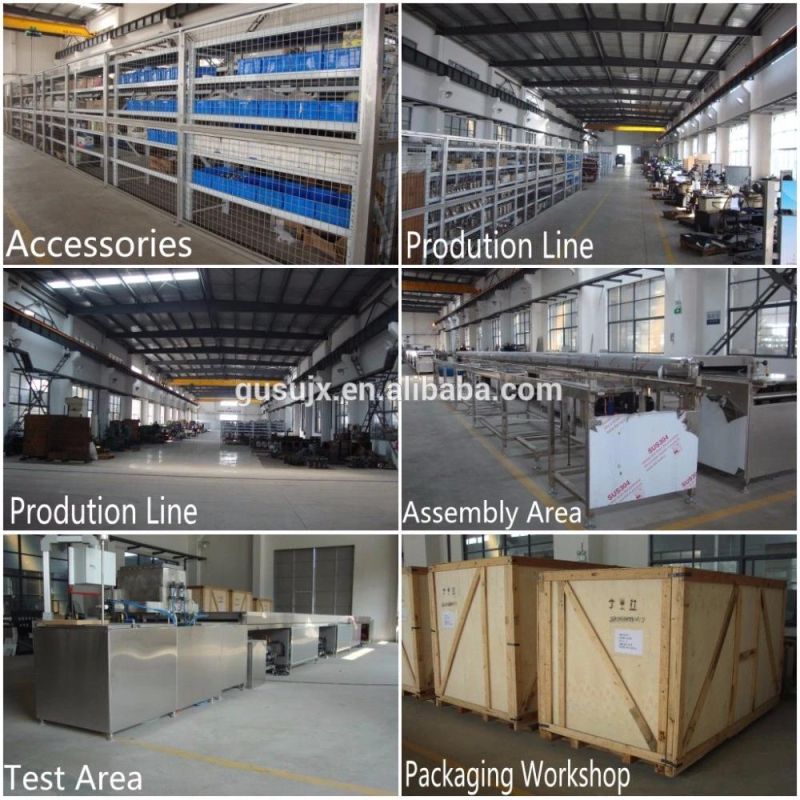

5.Company Information

Gusu Material Spreader machine mostly used in conjunction with our factory's TYJ 1000 enrober. It is specially designed to spread solid granular materials such as nuts, sesame, etc. after enrobing. The machine requires that the material to be spread should be of uniform size and thickness. The motor drives the screen wheel which feeds the material. The screen wheel in turn rotates the material spreading roller which uniformly spreads the material over the surface of the enrobed items.

Gusu Food Processing Machinery Suzhou Co., Ltd., formerly known as Gusu General Works of Food Processing Machinery Suzhou, founded in 1969, is also the first enterprise making complete sets of chocolate machinery in China and honored in this industry as "the Mother of Chocolate in China".

Over 45 years, Gusu insists on a corporate philosophy of people-oriented, be loyal to customers and credit management, we aim at the first class equipments and technologies worldwide in the industry, we connected with the food industry, scientific and technological enterprises and universities to make continuous improvements, innovations and development of the products in order to provide better service to customers. Products are sold all over China and more than 80 countries and regions.

Gusu expanded and moved to the new factory in 2014, "Suzhou Food Engineering Research Center" was founded in our new factory.

The purpose of Gusu is daring to scale the heights and striving for industry pioneer, we will continuously work on scientific research and innovations, provide customers with better and better service. We warmly welcome customers worldwide to Gusu to conduct and consult.

How to Order

1. Customer send us an inquiry.

2. Confirmmachine type, order quantity, price, lead time, payment term etc.

3.Our sales send the Proforma Invoice with company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5. Inform the clients that we have got the payment,and will arrange the production according to yourrequest, inform the estimated time

6. Production products photos will send to you for approval.

7. Clients make payment for balance and Ship the goods .

8. Order is finished when you receive the goods and satisfy with them .

9. Feedback to us about Quality , Service, Market Feedback & Suggestion.And we can do better

About after-sell service

Usually machine guarantee time is about 1 year . Within guarantee time . Machine breaking caused bymachine itself design defect , we are responsible for it .we can provided free charge breaking part .If machine breaking caused by humane factor , user need take responsibility for it , we will providedtechnical support .

About goods shipping

We have long time working shipping forwarder. We can do our best to send machine to your port safe and quickly.

4 About our online Service

24 hours online to solve any problem .

Your email will be reply within 12 hours .

Your satisfy is our pursuit .sincerely hope our cooperation

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23