H-Flame Shape Coated Blue Tungsten Carbide Burss With Standard Sizes

CANGZHOU BEWIN PIPELINE CO., LTD. / 2022-06-27

- Type:Carbide Burrs

- Material:Carbide

- Usage:Metal Drilling

- Shape:Cylindrical

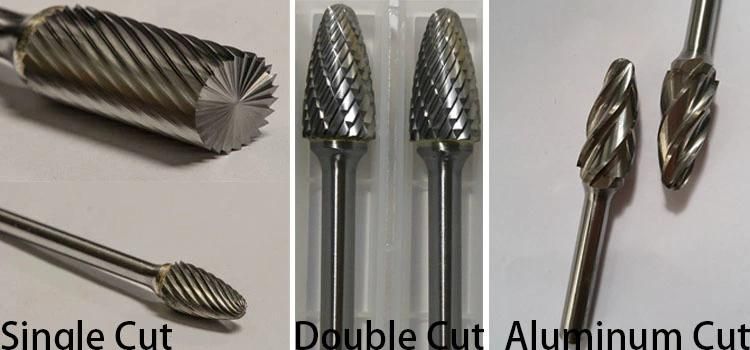

- Processing Methods:Cutting Tooth File

- Tooth Pattern:Bidentate Pattern

=== Base Info ===

- Model NO.:H0510M03

- Section Shape:Round

- Color:Unicolor

- Customized:Non-Customized

- Condition:New

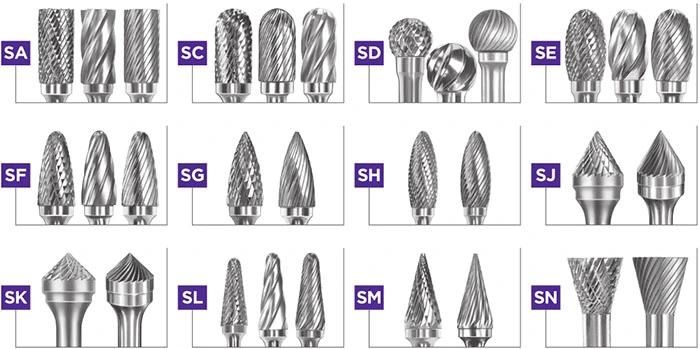

- Code:SA~Sn

- Shank:3, 6mm or 1,8", 1,4"

- Head Dia.:3mm or 1,4" ~ 25mm or 1"

- Length:70mm or 2-3,4"

- Transport Package:Plastic Box

- Specification:ISO

- Trademark:AT CARBIDE

- Origin:Chengdu, China

- HS Code:82080100

- Production Capacity:100, 000 PCS,Month

=== Description ===

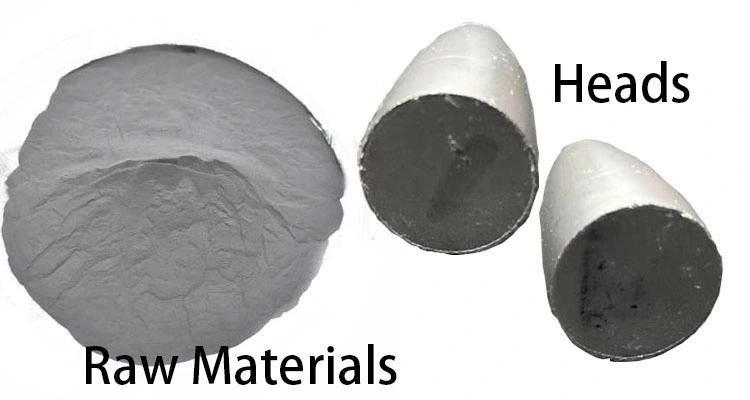

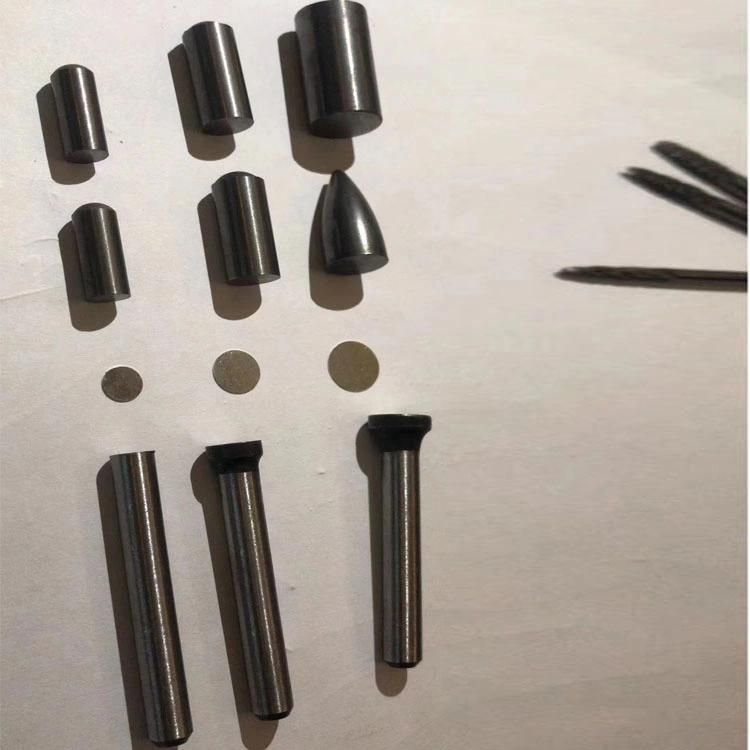

Structure

Lab inspected raw materials:

Structure

Feature

1. Full line for a wide range of applications.

2. Ferrous and nonferrous configurations for excellent finishes and efficient stock removal

3. Thirteen head shapes

4. A wide range of fluting styles

5. Extra-long shanks available.

6. Automated temperature-controlled brazing

7. Miniature burs

8. Special configurations available to meet specific applications requirements.

9. Machine-ground cutting flutes

10. Tool-to-tool consistency

11. Complete resharpening service available

12. Lab inspected raw materials.

13Head Shapes

Cut Types

Applications:

Mold & Die industry requires deburring tools that can handle the complexity of workpiece configurations and deliver accuracy required for tight tolerance applications. SGS burs are precisely ground on multiaxis CNC grinding machines offering unparalleled performance meeting the demands of challenging materials, including carbon steels, hardened steels, tool steels, stainless steels, and aluminum. • Chamfering, Creating a Radium, Weld Removal and Blending, Beveling, Repair

Castings & Foundry work requires safe, effective, and consistent performance when it comes to approaching high-strength and heat-resistant materials. SGS is an ISO Certified Company, utilizing rigorous quality control measures throughout the manufacturing process. Our quality burs are ideal for cast materials, including iron, steel, copper-based alloys, aluminum based alloys, exotic alloys, titanium alloys. • Parting Line Removal, Fin Removal, Finishing of Casting Risers and Flash Removal

Power Generation requires tooling specifically developed for efficient and economical removal of difficult to machine materials. SGS burs maintain superior tool life and control achieved through engineered geometry and consistent braze. Bur construction is torque measured to ensure braze strength and durability. • Turbine Manufacturing and Repair

Automotive machining means high production and cost control without sacrificing quality. The durability of carbide burs can be seen within automotive manufacturing or aftermarket service repair. • Flash Removal, Chamfering, Weld Removal and Blending, Beveling, Aftermarket Repair

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23