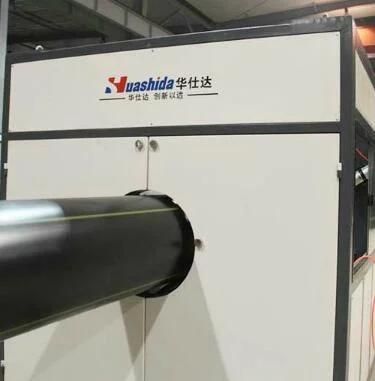

HDPE Pipe Multi-Layer Co-Extrusion Line

=== Base Info ===

=== Description ===

Basic Info.

Model NO. HSD Condition New Material PE, PP, Pb, Pert, ABS Control System Siemens PLC Application Gas Pipe, Water Supply Pipe, Foundation Pipe etc. Voltage 380V.50Hz Transport Package Standard Package Specification EN253, EN448, EN728, ISO1133, ISO8501-1. ISO9001 Trademark HSD Origin Qingdao China HS Code 8477209000 Production Capacity 50 Units/YearProduct Description

HDPE pipe Multi-layer Co-extrusion line

Advantages

1. Screw with barrier and mixing head; Barrel with slotting, to ensure good plasticizing and jellification, as well as large output and stable production.

2. Spiral type die, with advantage of low melt temperature, good mixing, low cavity pressure and stable production.

3. Exclusive calibrating and cooling system, with water film lubrication and water-ring cooling, to achieve demand of HDPE and PP raw material, then ensure roundness and high-speed production of thick and large caliber pipe.

4. Human Machine Interface; PLC controlling

HDPE pressure Pipe Extrusion Line is a pipe extrusion line developed by HSD company through assimilate and master technology introduced from abroad. It is applicable for extrusion of PE, PP, PB, PERT, ABS etc.

Plastic Pipes produced by this line have excellent stiffness, flexibility, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage and so on. It has become the first choice for the city gas pipe, water supply pipe, foundation pipe, landfill collection pipe, watermain, geothermal heating etc.

Structure

HDPE pipe extruding line is mainly composed of single screw extruder, die-head, vacuum forming tank, spray cooling tank, haul-off device, cutting device, and pneumatic discharging frame.

1. Single Screw Extruder

Single screw extruder is composed of AC motor, hard toothed surface reduction gear, extruding system, heating and cooling system, and electrical controlling part. AC motor transfer the power to reduction gearbox via V-belt wheel and make screw rotate at certain speed to adapt to extruding all kinds of plastics.

2. Die-Head

Die-head is mainly composed of mandril, neck mold, spiral body, cover, die-head body, bolts, and heating rings. The inside surface touching with plastic materials is polished and chrome plated to ensure plastic materials flow smoothly and to ensure no rusting. The uniformity of pipe wall thickness can be adjusted by bolts. The copper calibrating sleeve fixed in die-head is mainly used to cool down the fresh pipe and to calibrate the pipe outer diameter.

3. Vacuum Forming Tank

Vacuum forming tank is mainly composed of frame, stainless steel tank, vacuum system, spray cooling system, back and forth mobile device. When it is at work, the vacuum pump exhausts the air from the sealed tank to pressurize the fresh pipe cling to calibrating copper sleeve and to realize calibrating the pipe outer diameter. Spray cooling system is used to cool down the extruded pipe by water. Spray nozzles spray cooling water from all directions on pipe surface to cool down the pipe promptly.

4. Water Cooling Tank

Water cooling tank is mainly composed of frame, stainless steel tank, and spray cooling system. Spray cooling system is used to cool down the pipe further and to realize cooling completely and forming.

5. Caterpillar Haul-off Machine

Haul-off machine is mainly composed of driving device, haul-off chain caterpillar, clamping structure, adjusting system, side plate, and foundation bed. Haul-off caterpillars are AC motor driven and adopt frequency control of speed to adapt to different pipes extruding speed. It is also equipped with automatic length measuring device to realize cutter cutting at set length.

6. No-Dust Cutter

It adopts blade punching principle to realize no-dust cutting. It is mainly composed of cutting device, clamping device, structure synchronous mobile device, and frame.

7. Discharging Frame

The table surface is made of stainless steel. It adopts pneumatic overturn and discharging automatically.

Technical parameters:

| Model | SPEG-110 | SPEG-160 | SPEG-250 | SPEG-450 | SPEG-630 |

| Diameter(MM) | Φ20-Φ110 | Φ50-Φ160 | Φ63-Φ250 | Φ110-Φ450 | Φ315-Φ630 |

| Capacity(KG/H) | 250 | 300 | 350 | 600 | 900 |

| Total power(KW) | 180 | 200 | 210 | 298 | 522 |

Pre-Sales Service

Inquiry and consulting support.

Equipment pre-commissioning& testing support.

View our Factory.

After-Sales Service

Machinery warranty time is 12 months from the date of Bill of Lading. electronic parts 6 months.

Training how to install the machine and how to operate the machine.

Engineers available to service machinery overseas at customer cost.

Qingdao Huashida Machinery Co., Ltd is a professional plastic extrusion production line manufacture since 2003. The factory covers 34000 square meter. Our products such as HDPE pressure pipe for gas or water transmission, structural wall pipe extrusion line, corrugated pipe extrusion line . The products have been exported to Middle East, Russia, Africa. Turkey, Korea.

Our factory locates in Cheng yang Industrial area, Qingdao ,Shandong Province. we have been approved and got certificate ISO90001:2008 by SGS. All the customers are welcome to visit the factory.

If you need more information about this machine. just call us 0086-532-80999083, we can give you consulting service for this machine. or email to us

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23