Automatic Chicken Nuggets Forming Machine for Food Factory

AIRMAX AL CO., LIMITED / 2022-07-05

- Power Source:Electric

- Process:Frozen and Chilled

- Automatic Grade:Automatic

- Type:Meat Slicers

- Voltage:220V

- Customized:Customized

=== Base Info ===

- Model NO.:Njj400-V

- Flattening Thickness:3~30mm Adjustable

- Width of The Belt:600mm

- Speed of The Belt:3~15m,Min Adjustable

- Transport Package:Wooden Case

- Specification:2135*915*1320mm

- Trademark:KS

- Origin:Shandong China

- HS Code:8438500000

- Production Capacity:50sets,Month

=== Description ===

Basic Info.

Model NO. Njj400-V Flattening Thickness 3~30mm Adjustable Width of The Belt 600mm Speed of The Belt 3~15m/Min Adjustable Transport Package Wooden Case Specification 2135*915*1320mm Trademark KS Origin Shandong China HS Code 8438500000 Production Capacity 50sets/MonthProduct Description

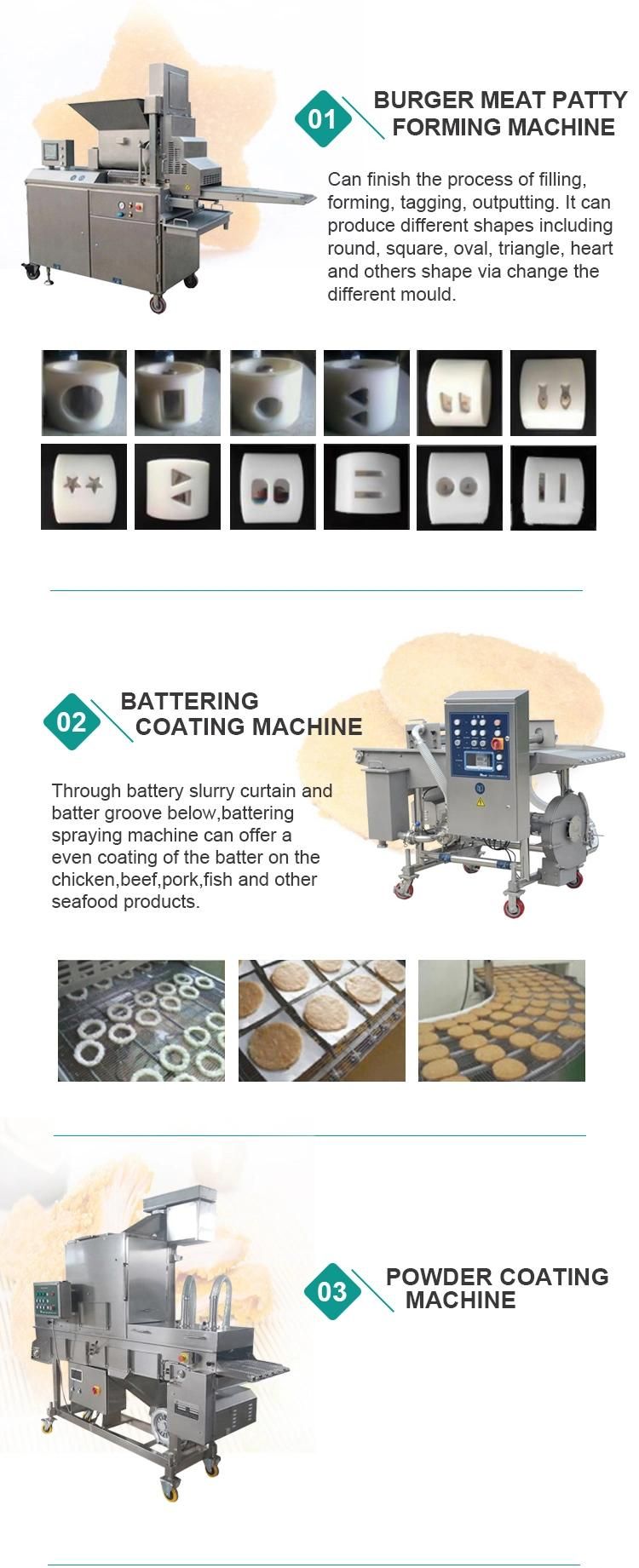

Updating the system comprehensively :

1. It can be suitable for metal forming plates

2. The protective grade for the electric apparatus parts reach to IP67

3. The speed increases to 70 stokes /min

4. Weight error margin ≤1.5%

5. New user interface

6. To avoid the operation mistake ,with high safe guarantee.

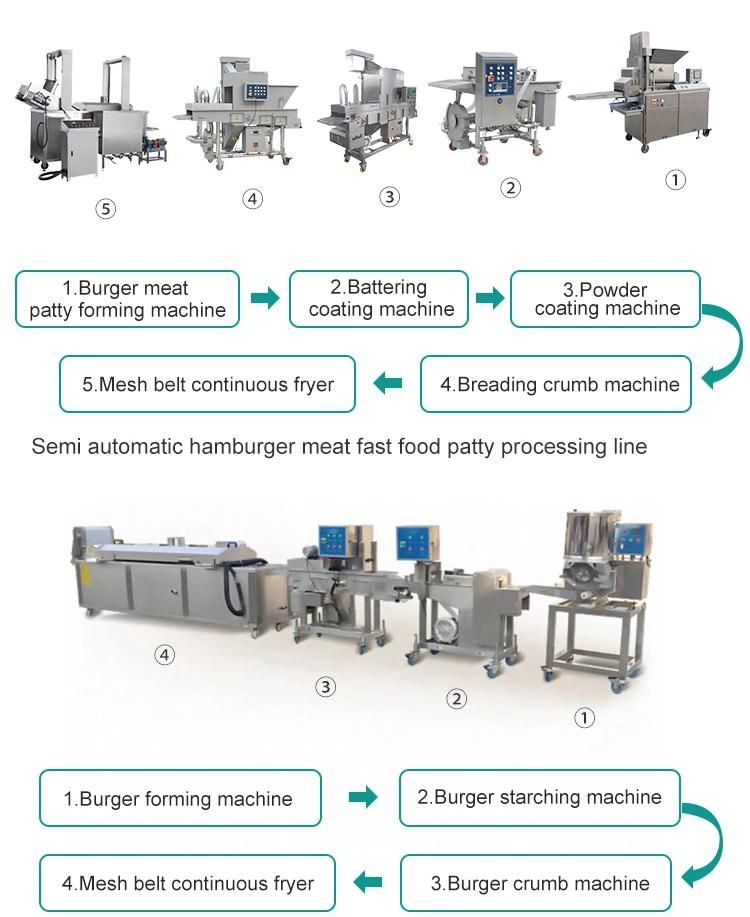

AMF600-IV, AMF400-IIAutomatic Multi Forming machine

can automatically perform various procedures such as meat filling, forming and outputting, and combine a fully automatic prepared

food line when connecting with the batter, preduster, fryer, cooker, instant freezer and packing machine. It adopts the method of

four-screw feeding system, greatly reduces the cutting of the material, and has better features of high production capacity and stable

quality.

Easy and convenient replacement of food and the accurate portion control realize the cost control of the production.

Widely handles in the forming procedure of meat, poultry, fish, shrimp and the potato, tuber crops. And it can be applied in the fields

of all kind of minced/sliced products for premier meat texture taste.

Electric apparatus parts: Using original Germany SIEMENS PLC processor with touch screen operation,

Chinese/English operating system and automatic failure alarm system.

Safe device: Magnetic protection switch (safe cover).

Hydraulic parts: Adopting the VICKERS, STAUFF, PARKER, INTERGRADTE HYDRAULIC original parts to guarantee the

stable running of the whole machine.

Pneumatically system: Adopting the completely Germany FESTO original system.

Stainless steel made and portion non-metal material, safe and reliable, in conformity with the standard of HACCP, and got the CE

authorization.

[ Automatic Multi Forming Machine Technical parameter]

Width of the belt | 600mm |

Air/water pressure | 6Bar/2Bar |

Power | 15.12Kw |

Production capacity | About 500-1000kg/hour |

Strokes | 15~60 strokes per minute |

The thickness of product | 6-40mm |

Weight Error | <=1% |

The maximum diameter | 150mm |

Filling pressure | 3~15Mpa adjustable |

Overall dimension | 3170x1176x2430mm |

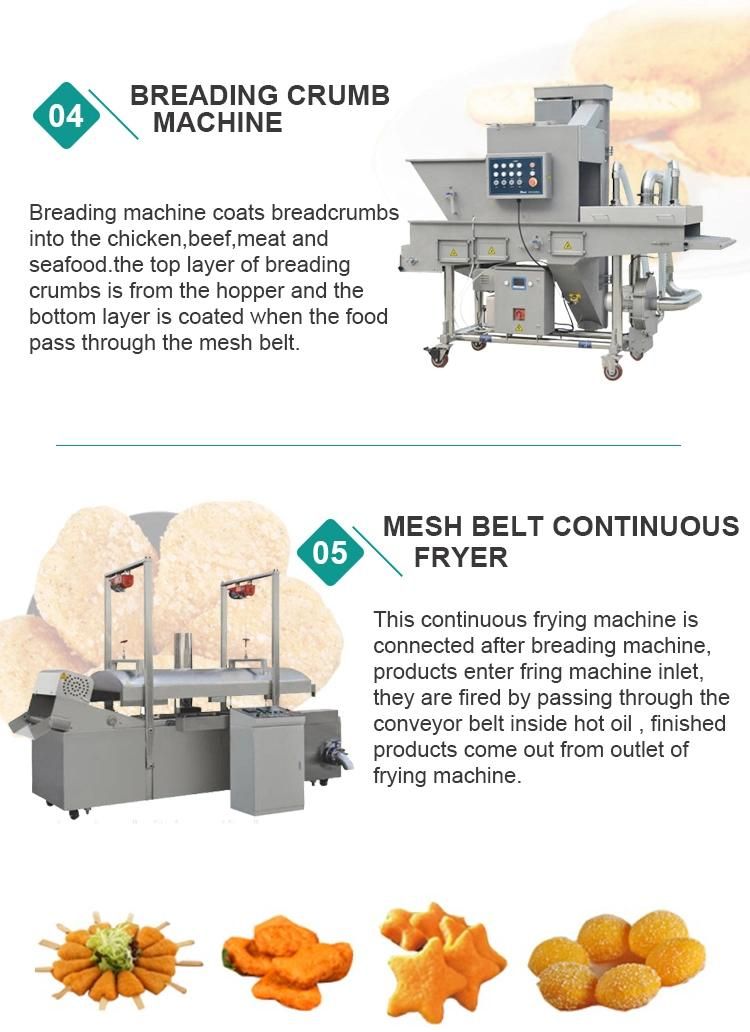

Features:

1.Convenient assembly design, easy to clean.

2.Easy adjustment.

3.Sprinkling device preventing products from sticking on conveyor belt.

4.Reliable protection device.

5.SIEMENS electric apparatus.

6.Can be connected to tenderizer to form production line.

7.Made of stainless steel, reasonable structure and reliable.

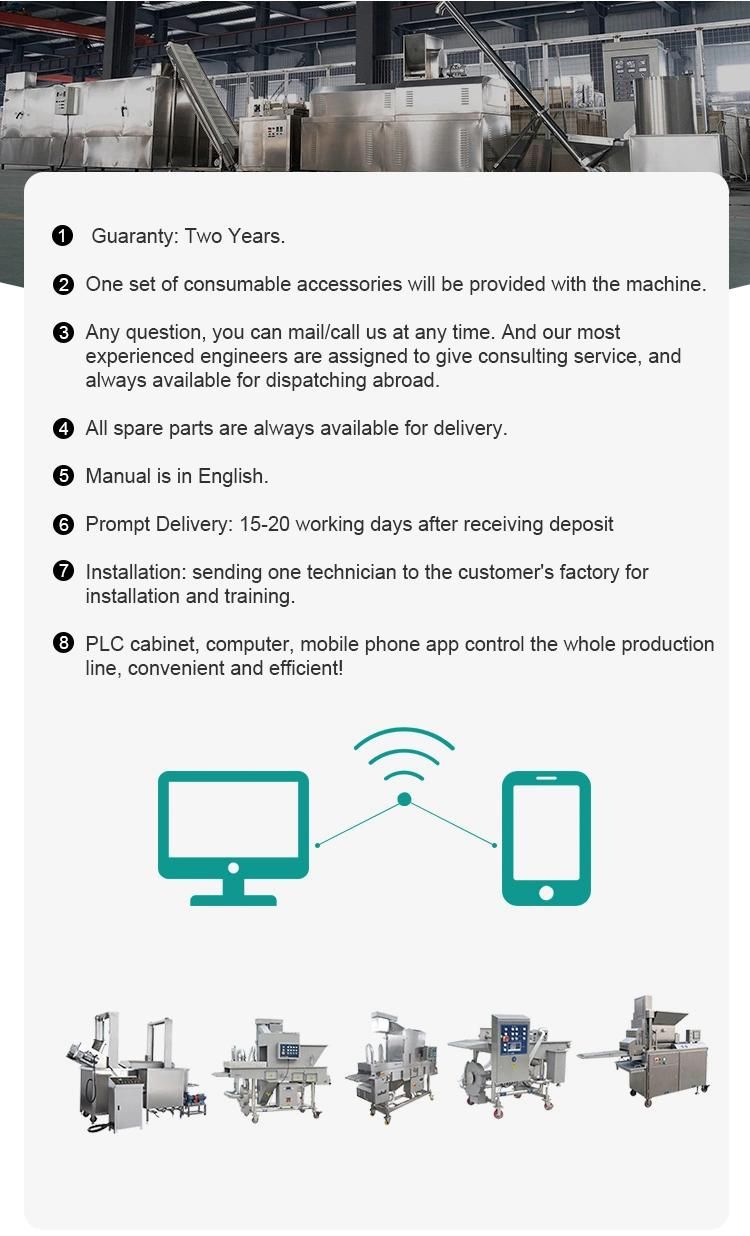

Our Services:

After-Sales Service

1.One year quality guaranty. The machine with main parts(excluding the

consumables)shall be changed free of charge when problems happened during the warranty

period.

2. Lifetime maintenance free of change.

3. Free training course at our plant.

4. We will provide the consumable parts at an agency price when you need replacement.

5. 18 hours on line service each day, free technical support by email or calling. If you meet the

problems, we can help to solve it with pictures, video, etc

6. Detailed manual and video to guide the users how to use the machine and maintenance, also

supply the specification settings for the speed and power to engrave or cut various materials.

Professional Service

From producing in our factory to shipping the goods directly to your port or company, we supply all-

in-one service for our customer. With the rich experience of dealing with shipping issue and custom

clearance, we can make the most economical delivery plan for you and ensure the quick leading

time. No matter quantity is our MOQ or very big, we take each customer as the only one

FAQ:

1. How about the documents after shipment?

After shipment, we'll send all original documents to you by DHL/TNT, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized

machines according to client's specific requirements, it would be 15 to 30 days.

3. Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW

price, clients need to arrange shipment by themselves or their agents.

4. How is the packing?

Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box

Package with Steel Belt Save space as much as possible for container loading

Packing and shipping:

Every machine is packed with great care and tough material. It is packed with cling films first and

then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the

top and bottom With this kind machine, all our laser machine can protect well during long trip by

sea or by train.We can transport machine by boat or by training, according to your requirement.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23