Die Cutting Machine for Hangtag (DP-520)

Kunshan Dapeng Precision Machinery Co., Ltd. / 2022-06-27

- After-sales Service:Online Service, Spare Parts

- Warranty:15 Months

- Species:Flatbed Die Cutting Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Metal Mold

=== Base Info ===

- Model NO.:DP-520

- Computerized:Computerized

- Automatic Grade:Automatic

- Application:Paper Packaging Materials, Stickers Products, EMI Shielding Materials

- Max Feeding Width:320mm

- Cutting Force:10 Ton

- Cutting Type:Half Cut and Full Cut

- Positioning Cut:Optional

- Warranty Period:12 Months

- Transport Package:Wooden Case

- Specification:SGS

- Trademark:DP

- Origin:Kunshan, Jiangsu, China.

- HS Code:8441100000

- Production Capacity:50 Sets,Month

=== Description ===

Basic Info.

Model NO. DP-520 Computerized Computerized Automatic Grade Automatic Application Paper Packaging Materials, Stickers Products, EMI Shielding Materials Max Feeding Width 320mm Cutting Force 10 Ton Cutting Type Half Cut and Full Cut Positioning Cut Optional Warranty Period 12 Months Transport Package Wooden Case Specification SGS Trademark DP Origin Kunshan, Jiangsu, China. HS Code 8441100000 Production Capacity 50 Sets/MonthProduct Description

DP-320 Die Cutting Machine for HangtagVarious insulating materials such as self-adhesive material, protective film, electronic shield materials, PVC, film, Mylar,

Copper foil, aluminum foil, foam, etc. And LCD module parks: Reflector, diffuser, gaskets, silicon tape.

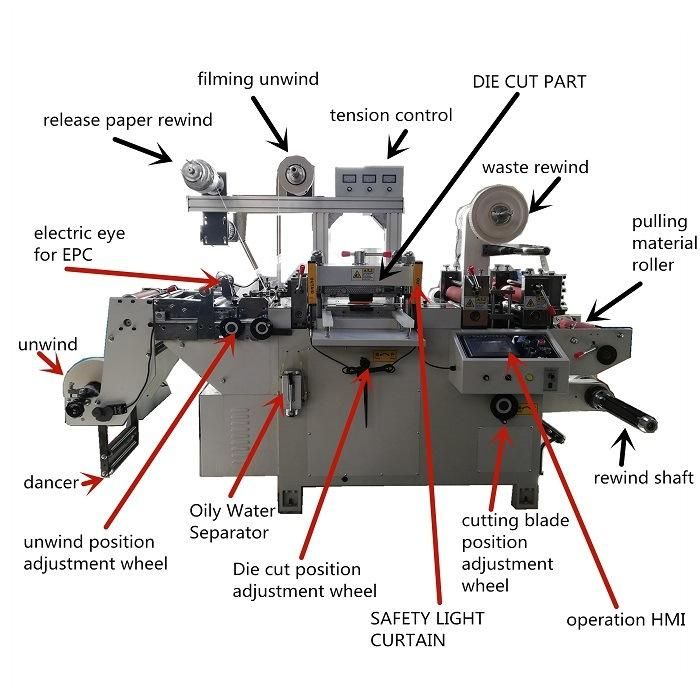

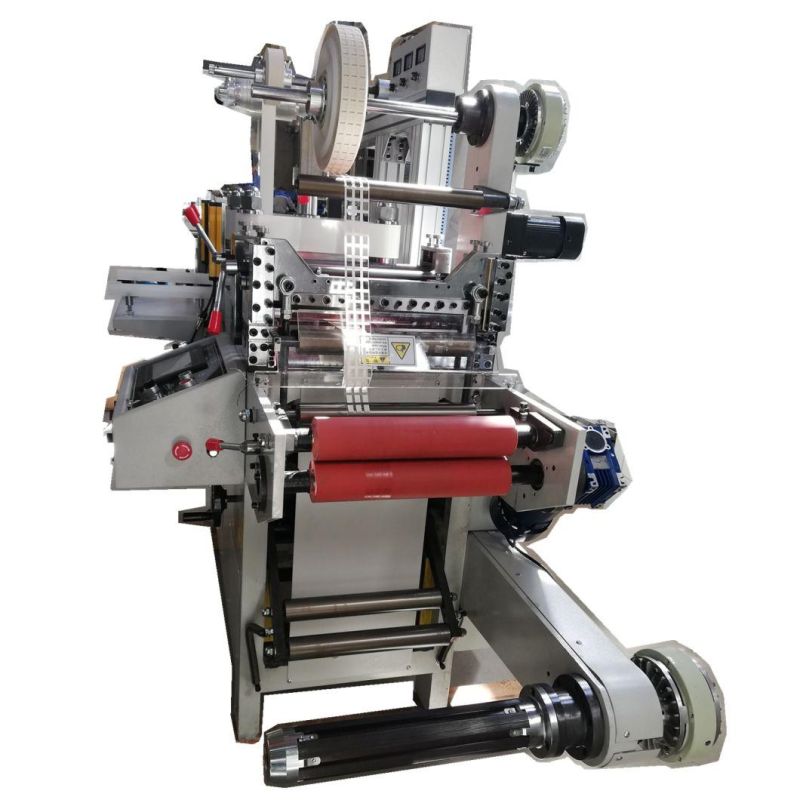

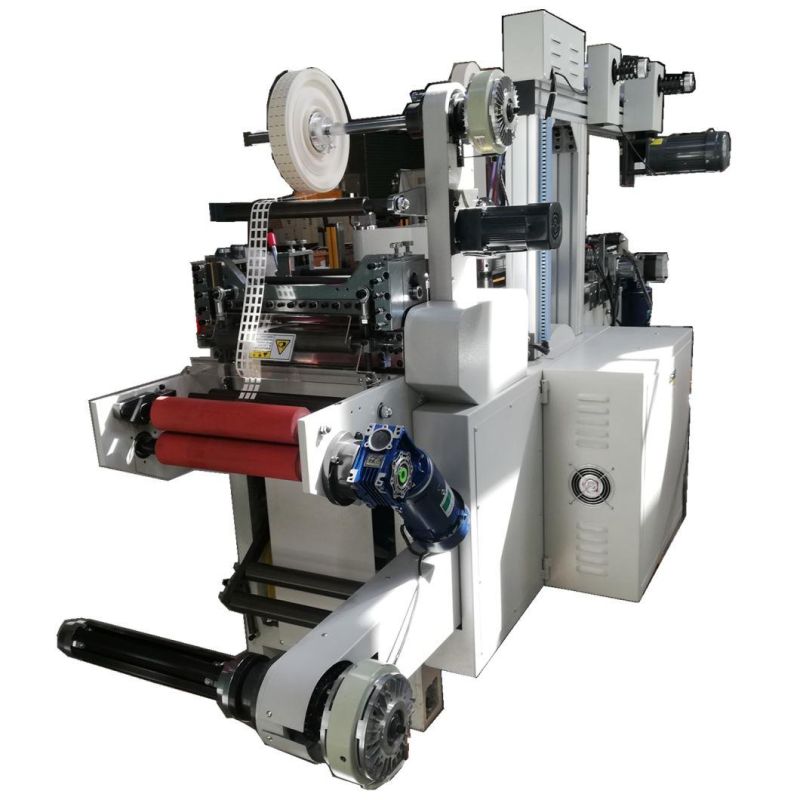

DP-520 Die Cutting Machine for Hangtag

The mahcine is equipped with an independent material feeding machine (material feeding mahcine with function of Laminating ).

Imported electric motor is adopted to discharge waste. Materials can be fed with a conveyer belt, and die cut to cut fully.

DP-320 Die Cutting Machine for Hangtag

Model: DP-320

Max Feeding Width ( mm ): 320

Cutting Area (mm): 300*300

Cutting Speed (T/M): 20-100

Position Accuracy ( mm ): ± 0.1

Power of Main Engine ( kw ): 4

Height of Knife Mold(mm): 23.8

Pneumatic Pressure(MPA): 0.3

Weight(KG): 2800

Size ( mm ): 2400*2000*1850

Voltage(V )380

Standard Function: Material feeding ---Binding ---Die cutting --Waste Discharge --- cutting or withdraw(rewinding) material

Standard Configuration: One host, 1 automatic feeding device, 1 slicer, 1 thin upper board, 1 thicker upper board

1 low thicker board, 1 safety equipment, 1 material detecting infra red device

Optional Accessories:

1. Laminating protection film device added between mold base and labor wheel

2. Heating equipment

3. Roller being wrapped with rubber

4. Waste discharging equipment with ejection pin

5. Collecting equipment

6. Metal mold equipment

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23