Automatic Thermoforming Machine for Plastic Lid and Tray

Zhuzhou Lihua Cemented Carbide Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. DHBGJ-480L Shaping Mode Die Molding Application Machinery & Hardware, Food & Beverage Driven Type Pneumatic Computerized Computerized Transport Package Wooden Packagintg Specification SGS Trademark DONGHANG Origin China HS Code 8477409000 Production Capacity 50 Sets/MonthProduct Description

Characteristic:DHBGJ-480L It's a new type one that combines advantages of several types of main forming machines and also brings to more improvement and innovation.

With easy operation, calm running, convenient maintenance and stable function.

It can produce PVC, PS, PET etc. All kinds of covers.

it is two line of forming area, it works with servo motor and hydraulic, so the machine will be much more stable than others.

Functions and Features

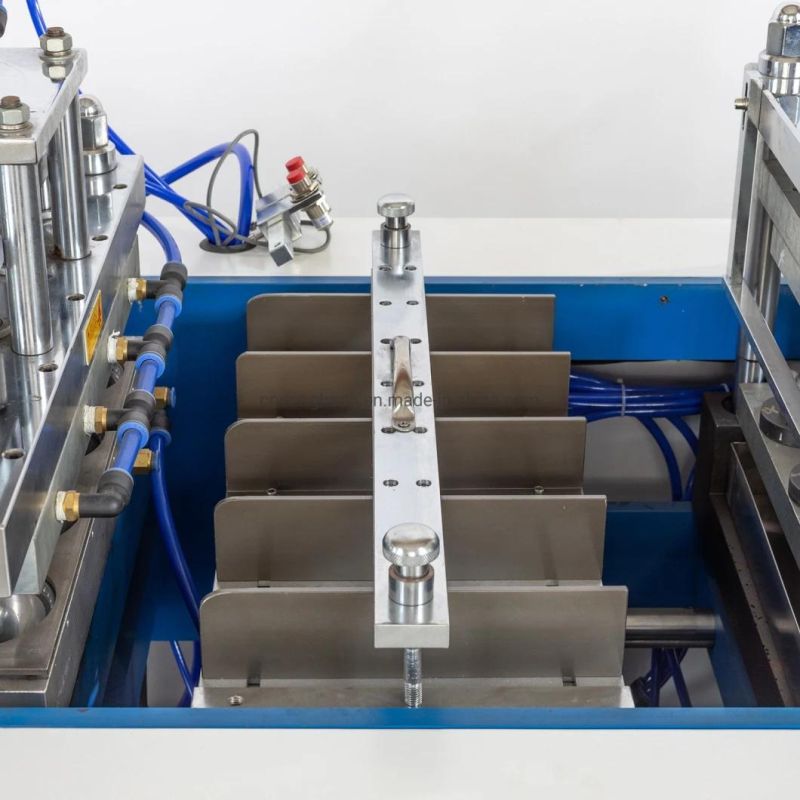

1) Mold adopts clamping plate, easy to adjust and install.

2) Main motor adopts servo governor: Cutting frequency is adjustable of 10~28 Time/min. Moderate the suitable cutting frequency on the basis of stoke length and difficulty of forming.

3) Servo feeding corporate with squeeze motion. Smooth running, process synchronized, the maximum line control is 240mm, it means the dimensions can designed differently in this range.

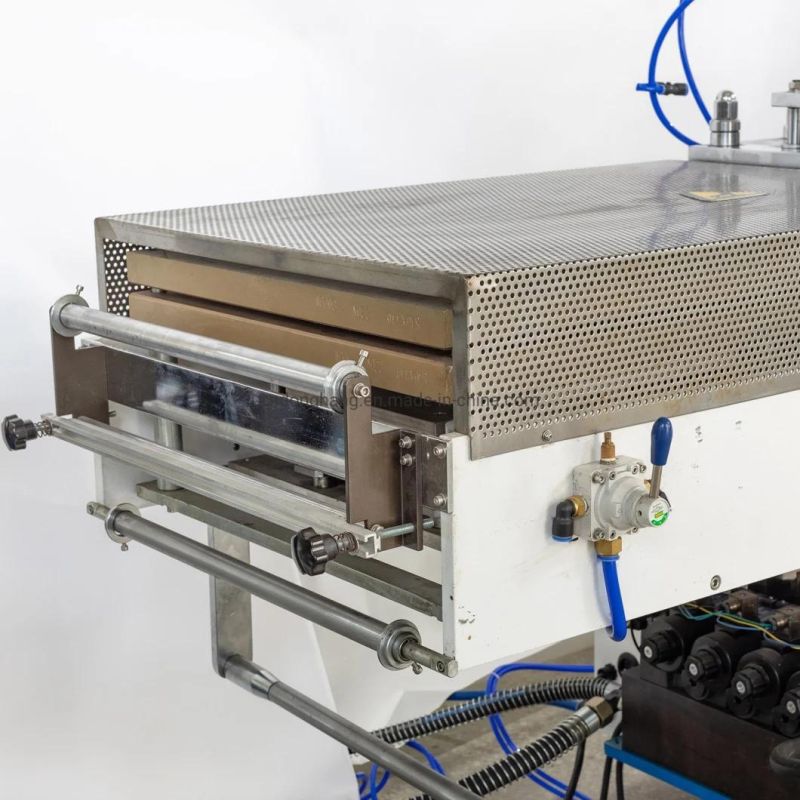

4) Forming heating plate automatically close and open. It can power on delay, limits the waste of materials in once time. The heating power and temperature can be lowed by adopted contact heating of the plate. Through which it saved energy and enhance the stability of plastic piece.

Technical Data

| Punching Frequency | 20-35time/min |

| Adjustable scope of Travel | 30-160mm |

| Max Forming Depth | 50mm |

| Max. Forming Area | 260mm*450mm |

| Air-compressor | <0.2m 3 /min |

| Pressure | 0.4-0.7MPa |

| Power | 20Kw |

| Overall Dimension | 4200*850*1700mm |

| Weight | 2000Kg |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23