1000W Raycus Laser CNC Sheet Metal Laser Fiber Cutting Machine

Bestpoly (Xiamen) Plastic Co., Ltd / 2022-06-23

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Gantry Type

- Laser Classification:Semiconductor Laser

=== Base Info ===

- Model NO.:FLC-3015E-1000W

- Laser Technology:Laser Fusion Cutting

- Processing Material:Carbon Steel; Stainless Steel; Aluminium; Copper

- Processing Size:3000*1500mm

- Optional Processing Size:4000*2000mm; 6000*2000mm; 6000*2500mm; 12000*2000m

- Warranty Time:24 Months After Arriving at User Factory

- Laser Source:Raycus, Max, Jpt

- Laser Power:1000W

- Servo Motor:Yasakawa

- Cutting Head:Raytools

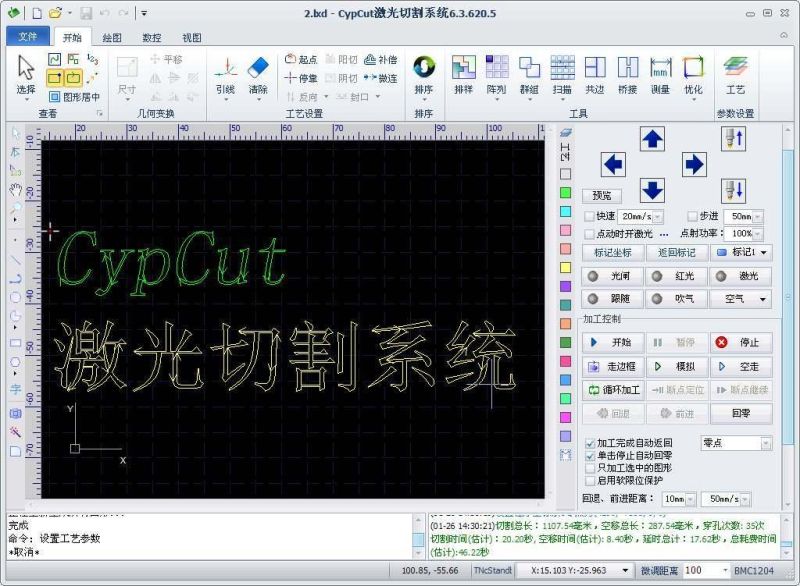

- Control System:Cypcut 2000

- Delivery Time:15-25 Days

- Package:Wooden Pallet

- Support Format:Plt, Dxf, BMP, Ai and So

- Cooling Method:Water Cooling

- Power Supply:380V 50Hz, 220V 60Hz

- Dimension:4500*2400*1500mm

- Transport Package:Wooden Pallet

- Specification:3500Kgs

- Trademark:CCILASER

- Origin:China

- HS Code:8456110090

- Production Capacity:100 Sets Per Month

=== Description ===

Whether it is mass production or small batch production, it can be satisfied. If compared with the traditional punching machine, the cost of mold opening is also required, and the product is single. If the product shape needs to be changed, the mold needs to be reopened. However, the flexibility of the laser cutting machine solves this problem well, and it can be easily processed by inputting the drawing into the program.

FSCUT2000 medium power laser cutting system is a full-solution open-loop control system specially designed for sheet metal processing industry, which owns a wide market share with the features of easy to install and adjust, excellent performance and fully integrated solutions

3. Application:

Fiber laser Cutting Machine meets the parts processing requirements of most industries, working accuracy is stable.

At present, laser cutting machines have been widely used in electronics, electrical, mechanic al hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

The fiber laser cutting machine is used in sheet metal processing, aviation, aerospace, electr onics, electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships.

4. Main Components (According to final confirmed configuration)

5. CCILASER Factory

6. CCILASER Staff Style and Exhibition Show

7. CCILASER CERTIFICATE

8. CCILASER Quality Control System

9. Exporting Package and Delivery

6. Contact Information

To be continued..

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23