16-32mm PVC Dual Tube Making Machine with Ce Certification

Hubei St. Bairui Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

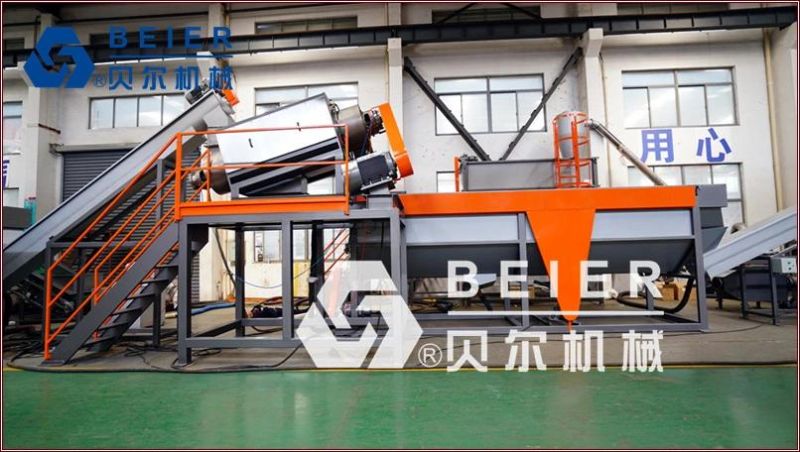

PE film recycling machine

KWELL Company provides best plastic recycling solutions, including sorting, shredding, crushing, washing, drying. The recycling machine is suitable for LDPE film, PP woven bag, PA fishing net…etc.

Plastic film is valuable secondary resources in recycling market, recycled film can be used for granulating, injection molding, extrusion, film blowing and to produce wide range of products.

The waste plastic film to be processed can be in different conditions in terms of humidity, contamination, form. The plastic film in recycling market are basically divided into the following families:

Agricultural film (including greenhouse, mulching,, tunnel and banana film)

Post-consumer film (including film from landfills and selective collections)

Post-commercial and post-industrial film (including material 100% stretch)

Estimated Plant Parameters

Supply(m³/min)

Machine List Components of Pet Bottle Washing Line:

Label Remover machine---Sorting system---PET Crusher machine---Flakes Floating washing tank---Hot Washing system,---Frication washing system---dewatering machinery and fin dust label separator machine---hot air drying system and the Packing system

Beier Machinery film washing lines can assure a precise and efficient decontamination of the post-consumer film with both cold and hot washing systems, adopting the most efficient recycling technologies. The final target of post-consumer film recycling is to obtain the highest valorization of a very poor starting product, deriving mostly from waste collection.Beier Machinery film washing line can properly treat any contaminated post consumer film and bring the final output washed flakes back to be reused (alone or blended with other materials) even in new film blowing applications.

Our certification

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23