Plastid PVC Bathroom Kitchen Decoration Profile Panel Ceiling Wall Panel Extrusion Making ...

Ningbo Zhaoke Int'l Imp. & Exp. Corp / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ65/132 Computerized Non-Computerized Certification CE, ISO9001:2008 Customized Customized Condition New Inverter Brand Scheider or Delta Contactor Siemens Temperature Controller Omron Driving Motor Siemens Motor Power 37kw Heating Power 24kw Voltage 380V/3p/50Hz or as Request Machine Color Standerd or as Reqeust Extruder Type Conical Twin Screw Extruder Extruder Model Sjsz65X132 Capacity 200-250kg/H Operator 2 Raw Material PVC Powder + Coc03 Final Product Wall & Ceiling Panel Feeding Screw Feeder Transport Package PE Packing Film or Wooden Case Specification SJSZ65x132 Trademark SUKE Origin Qingdao HS Code 8477800000 Production Capacity 50 Sets Per YearProduct Description

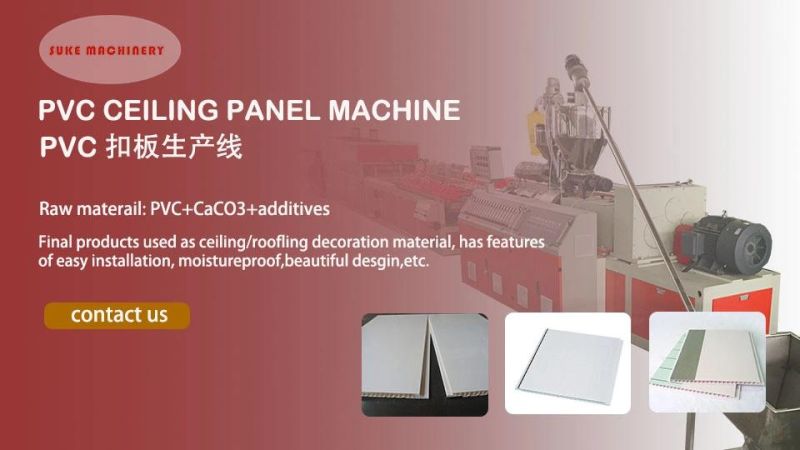

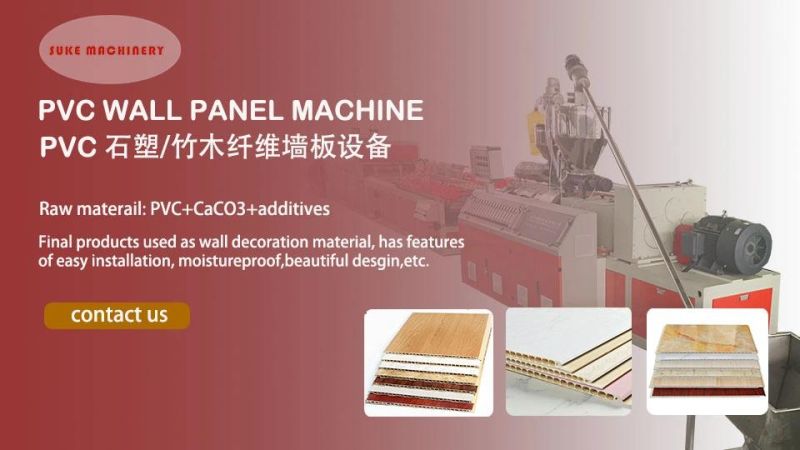

Plastid PVC Bathroom Kitchen Decoration Profile Panel Ceiling Wall Panel Extrusion Making Machine

----Machine Introduction----

PVC WPC decoration wall panel extrusion production line is used to produce PVC/WPC wall panel with different size, such as 300mm, 400mm, 500mm, 600mm wide, etc.

Changeing some of parts, this line can also produce wpc profile.

According to the didferent formula, should mix the PVC powder with additives in a ratio. After mixing, put the raw material into the extruder by screw feeder. By heating and mixing in extruder, the raw material will change to fluid and extruded into mould. Out of mould, wall panel will be shaped and cooling by platform. Through the tractor, cutting machine, finial end on collect platform for packing.

----Machine Features----

1. Cutter is equipped with PLC control system. which helps with setting the length and precise cutting.

2. Good Brand, ABB frequency, SIEMENS motor, Schneider buttons, OMRON temperature controller.

3. Screw and barrel are from jinxing company, which is the best supplier in china.

4. The speed reducer is from jiagnyin company,etc.

----Equipment List----

Equipment list of PVC WPC Decoration Wall Panel Extrusion Production Line

1. Screw Feeder

2. SJSZ65x132 Twin screw extruder

3. Wall panel mould

4. Shaping platform

5. Haul-off machine

6. Cutting Machine

7. Collect platform/

Auxiliary machine for option:

1. SWP 400 Crusher

2. 300/600 Mixer

3. SMP400 Pulverizer

4. 10P chiller.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23