Cottonseed Miscella Refining Plant/Refining Machine/Production Line/Project

Anping County Dinghe Wire Mesh Co., Ltd. / 2022-07-04

- Type:Oil Refining

- Application:Cottonseed

- Voltage:380V

- Appearance:Horizontal

- Press Materials:Cottonseed

- Press Series:None

=== Base Info ===

- Model NO.:C30-1000

- Condition:New

- Customized:Customized

- Transport Package:Container, Bulk

- Specification:30-1000t,d

- Trademark:CHEMSTA

- Origin:China

- HS Code:8479200000

- Production Capacity:30-1000t,D

=== Description ===

Basic Info.

Model NO. C30-1000 Condition New Customized Customized Transport Package Container, Bulk Specification 30-1000t/d Trademark CHEMSTA Origin China HS Code 8479200000 Production Capacity 30-1000t/DProduct Description

Product Description

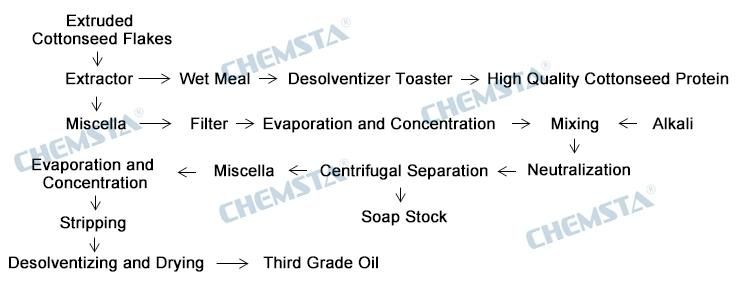

Cottonseed Miscella Refining Line in Extraction Workshop

Major Device

Filter, evaporator, acid weighing pump, alkali weighing pump, acid reactor,alkali reactor,disc centrifuge, heat exchanger, desolventizing device, vacuum system, holding tank, electrical control equipment.

Production Process

Raw Materials: cottonseed flakes produced by an extruded Cottonseed Extraction line

Production Capacity: 100-1000t/24h cottonseeds

Neutralization

Neutralization and saponification process for miscella refining line matched with 600t/d extruded cottonseed extraction line

Miscella Evaporation

Evaporation process miscella refining line matched with 500t/d extruded cottonseed extraction line

Desolventizing and Drying

600t/d extruded cottonseed extraction plant layout

Features

In order to simplify production process and save steam, refining and desolventizing processes are all carried out directly in the leaching workshop to produce third-grade cottonseed oil. Our refining line is also able to efficiently prevent pigment consolidation caused by high temperature and eliminates common difficulties of refining. The refined oil obtained features brighter color and higher quality than any other refining processes. The refined miscella can efficiently withstand emulsification, which hinders soap from entering the neutral oil and further reduces neutral oil loss. As a result, high refining yield can be achieved. Evaporators and dryers adopted are capable of prevent dirt from accumulating on them, which ensures high evaporation efficiency and decreases cleaning frequency. The whole refining process almost doesn`t create any waste water or water solids, which contributes to environment protection.

We also provide the following project and equipment:

Oilseed Pretreatment Project

Oilseed Pressing Project

Oil Extraction Project

Oil Refining Project

Cottonseed Miscella Refining Project

Low Temperature and Edible Soybean Meal Project

Soy Protein Concentrate Project

Soy Protein Isolate Project

Cottonseed Protein Project

Full Fat Soybean Powder Project

ASME Pressure Vessel

ASME Heat Exchanger

Looking for ideal High Quality Acid Reactor Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the High Quality Alkali Reactor are quality guaranteed. We are China Origin Factory of High Quality Miscella Evaporator. If you have any question, please feel free to contact us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23