Type 1000 Dried Noodle Production Line/Dried Noodle Making Machine/Dried Noodle Production ...

Ningbo Fantasy Packaging Co., Ltd. / 2022-07-04

- After-sales Service:1 Year

- Warranty:1 Year

- Processing Material:Wheat Flour Material

- Application:Fast Food

- Customized:Customized

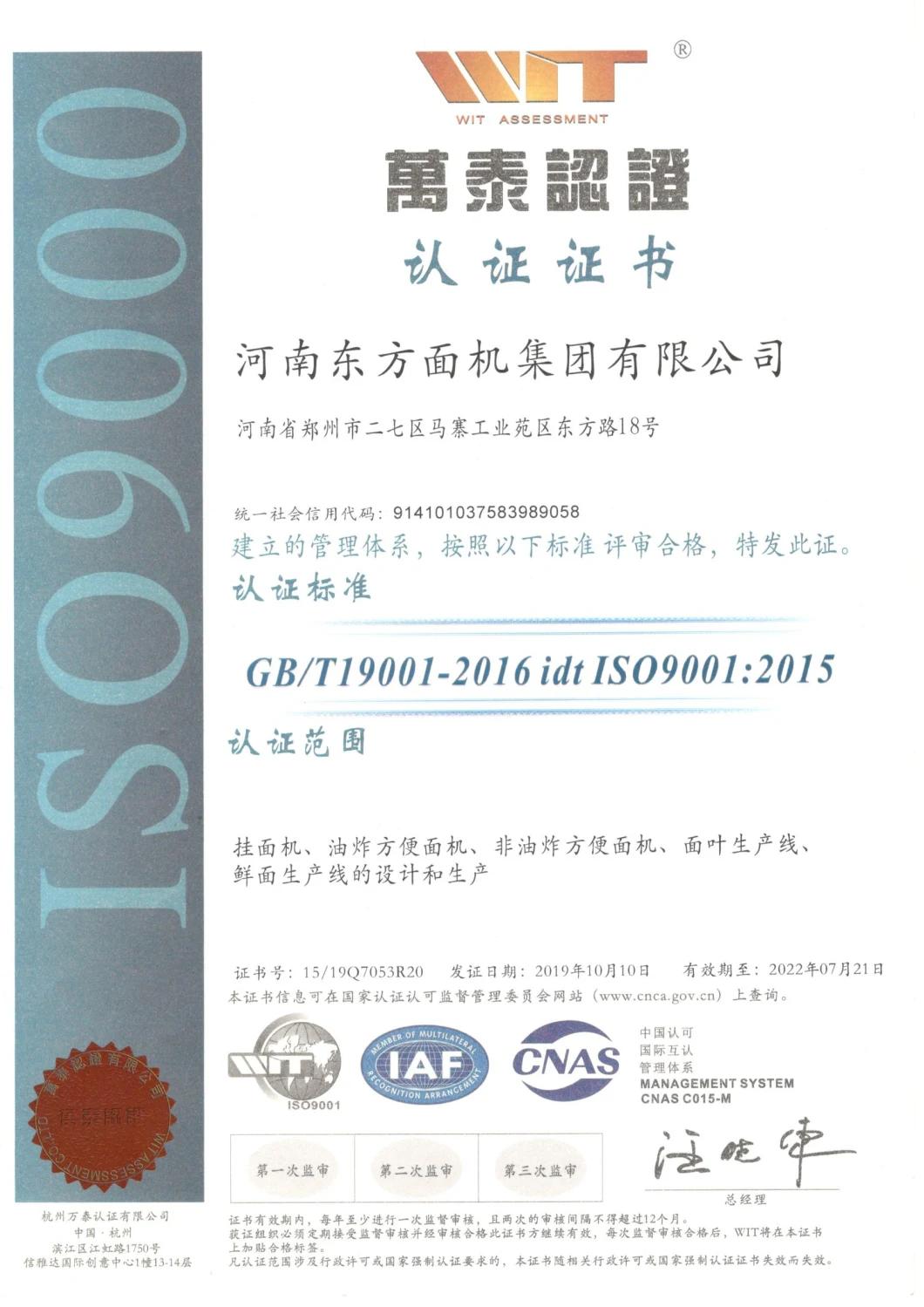

- Certification:CE, ISO9001

=== Base Info ===

- Model NO.:1000

- Power Source:Electric

- Automatic Grade:Automatic

- Product:Stick Noodle Egg Noodle

- Material:Stainless Steel 304

- Raw Material:Wheat Flour

- Product Shape:Long

- After Sales Service:Seller Send Engineer for Installation and Training

- Transport Package:Container

- Specification:60m*13m*3.5m

- Trademark:dongfang

- Origin:Zhengzhou

- HS Code:84381000

- Production Capacity:45t,24h

=== Description ===

workers:( not including packaging workers )

3. Product detailsContinuous dough mixer

The highly automatic continuous dough mixer can save labor and construction cost by combining flour feeding, water supplying, mixing and dough feeding together. The dough absorbs water more fully and evenly. Aging conveyor

Aging conveyor

Aging conveyor Aging the dough under Stationary state,improve the dough gluten quality

Rolling Machine

Rolling Machine adopt different diameter roller rolling, is advantageous to the gluten forming;Ripple roller rolling,make the dough sheet draging in multi directions. improve the dough sheet quality. each roller adopt independent driving. Effectively guarantee the reliability of the transmission, and the structure is simplified, easy to maintenance.

Automatic drying room 1

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying;Through frequncy control adjusting the humidity and tempreture of each drying section, convenient and reliable; Clever drying room design can make the both end humid air flow toward the middle, , reduce the energy consumption 20-30%.

Automatic drying room 2

Automatic drying room 2

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying;Through frequncy control adjusting the humidity and tempreture of each drying section, convenient and reliable; Clever drying room design can make the both end humid air flow toward the middle, , reduce the energy consumption 20-30%.

Noodle cutter

Noodle cutter

Noodle cutter highly automatic,With the technology of speed adjusting system, noodle length can be controlled as desired.

4. Finished product

5.Our company

Henan DongFang Noodle Machine Group Co., Ltd. was founded in 1975, It is a high-tech company famous in China and abroad for its research and development, manufacture and sale of "DONG FANG" brand stick noodle machines and instant noodle machines and other food machinery.

The company's main products, the whole set of stick noodle machine and instant noodle machine have passed ISO9001 and CE international certification,and has been leading the technology trend of the industry.

6.CE certification

7.Our customer

FAQ:

1. Q: Are you manufacturers?

A: We are manufacturer of noodle machine with 40 years experiences, and more than 40 engineers, who can design the machine according to your special request.

2. Q: What is your noodle machine for?

A: Our noodle machine can produce many kinds of noodles, such as stick noodles, fresh noodles, instant noodles, fried instant noodles, non fried instant noodles, chowmein noodles, noodle leaves, extruding noodles, etc.

3. Q: How many countries have you exported to?

A: we have exported to more than 40 countries, such as Canada, Turkey, Malaysia, Nigeria, Bangladesh, Indonesia, India, etc.

4. Q: What is your delivery time?

A: 40-50days. For special request, we can deliver the machine within 30 days.

5. Q: What about aftersales service?

A: We have 30 after-sales service staff with overseas service experience, will to assemble the machine and train the customer's workers when machine arrives.

After sales service commitment

In order to provide better service for customers, to make customers feel more at easy after cooperation with our company.

Our company promise as follows:

1. Three guarantees should be implemented within one year from the date of completion and commissioning of the equipment.

During the warranty period, the company is responsible for repair and replacement of spare parts free of charge in case of failure due to internal quality problems of the equipment (excluding human factors).

2. After the equipment is delivered for use, the supplier should be provided with free technical guidance and training by electrical personnel and mechanical operators in the demander, including can learn after teaching and accommodation.

3. When the demander's equipment is in normal continuous production, the supplier shall send technicians to make a return visit by telephone or email once every six months, and assist the demander in equipment maintenance if there is any problem.

4. After the warranty period. The price of the equipment parts required by the demander (refer to the self-made parts of the supplier) can be reduced by 10% for timely supply.

5. The above services shall be provided until the demander stops using the equipment. During the use of the equipment, if the supplier has new technical projects launched, it can give priority to the technical transformation of the equipment for the demander, and only charge the cost.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23