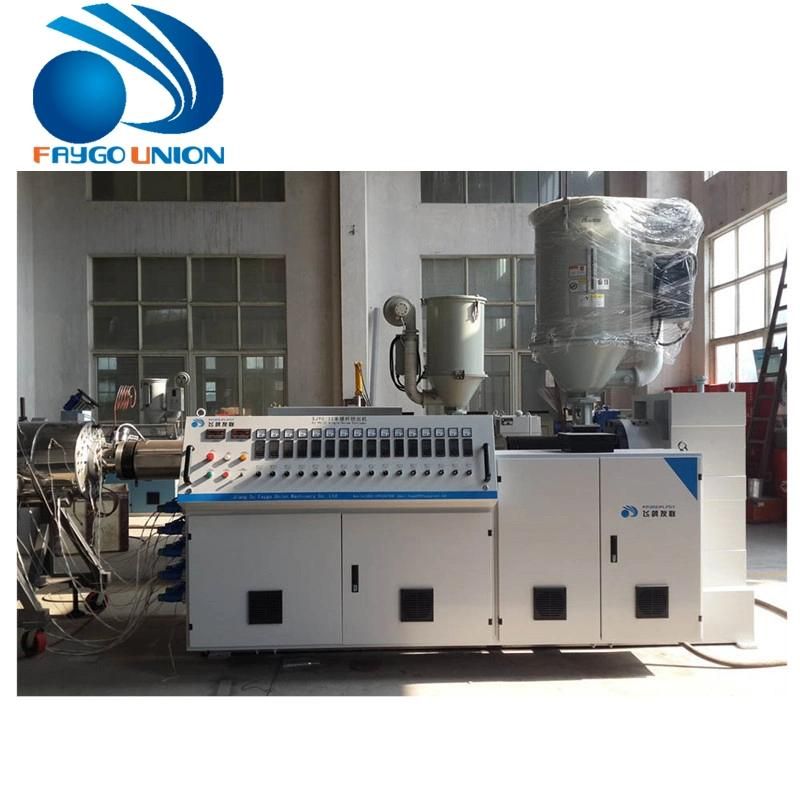

PPR Pipe Extruding Machine Pipe Plastic Pipe Making Machine

Qingdao Kaier Xiang Diamond Tools Co., Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Extruder Model

SJ65/33

SJ75/33

SJ90/33

SJ120/33

SJ150/33

Max. Diameter(mm)

75

160

250

315

630

Installation power(kw)

65

150

200

280

420

Drawing speed(m/min)

0-12

0-8

0-6

0-4

0-2

Total length(m)

28

36

50

66

72

Output(kg/h)

80~120

80~150

180-260

300-400

450-600

1) Different pe pipe producing line should be with different machines and extruders. So if you are interested on pe pipe making machine, you should check your market firstly, it is better if you can know every pipe diameter wall thickness, which will help us know how many mandrel together with mold we should supply you.

2)pe pipe producing line can be used to produce both PE pipes and PP pipes, PE pipes are widely used in electric, water drainage and water supply, and PE pipes is popular all over the world.

3)Except ppr pipe producing line we also produce PVC pulverizer, PE color mixer,PVC profile line and PVC gutter extrusion, WPC board extrusion, PP/PE pipe extrusion machine, PP/PE film washing recycling line, PET bottle washing recycling line, PET bottle blowing machine and so on.

If you are interested on above, please check our web faygounion.en.made-in-china.com to confirm which is suitable for you.

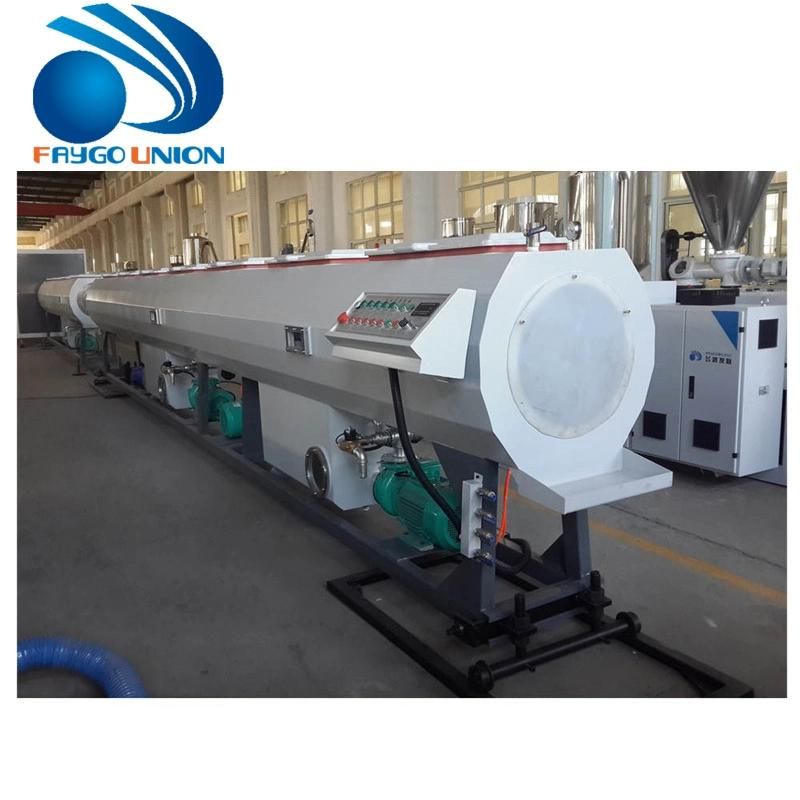

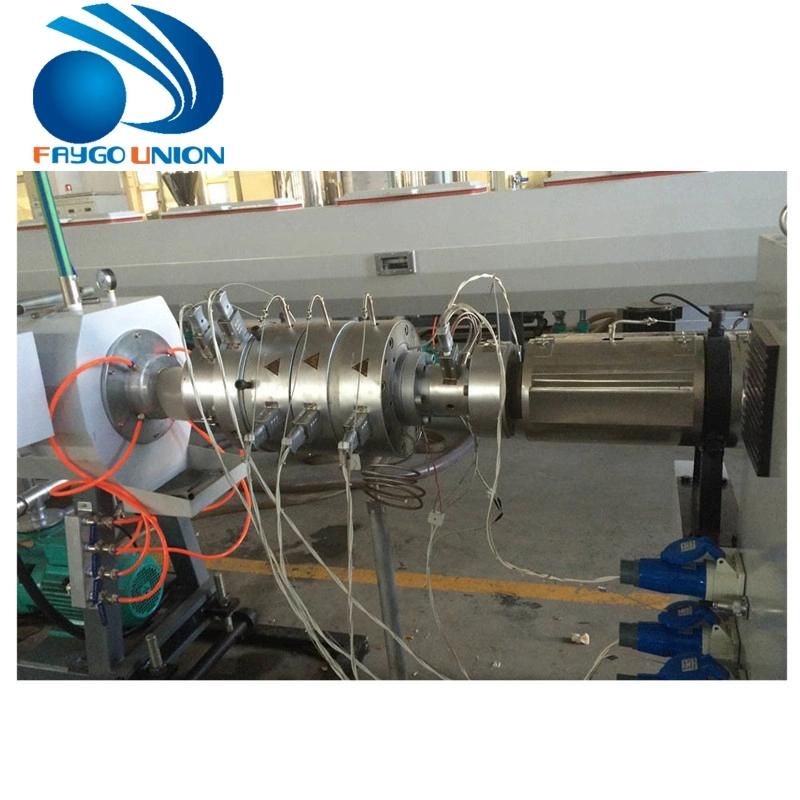

Equipment list of PP PE pipe making machineCompulsory devices

Our HDPE / PE Pipe Production Line has the features as below:

1. Good components: Siemens Beide main motor, ABB inverter, Eurotherm DC regulator, Siemens & Schneider low voltage electrics, Omron temperature controller

2. Good design and good outlook: We design the machine for easier operation and stable performance. The haul off machine and cutter is fully closed for safety purpose. Planetary socket is using in some machines for wire connection.

3. Our engineers and technicians have more than 10 years experince, they know pipe machine well and make good pipe machine.

If you need good pipe production line, please contact us now.

Company Show:

Jiangsu Faygo Plast Machine Co., Ltd. is a professional company which devote ourselves to the development, research and production of plastic machines. Faygo has high quality products, accurate delivery time,quick response to after-sales service and very competitive prices.

Main products include: Plastic pipe production lines ,plastic board and profile production lines,plastic granulation production lines,plastic washing and recycling lines, production line supporting machines etc.

Shipping Show:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23