PP Pet Tape Pet Belt Extruder Machinery Pet Strapping Band Production Plant

Dongguan Yize Precision Cutting Tool Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

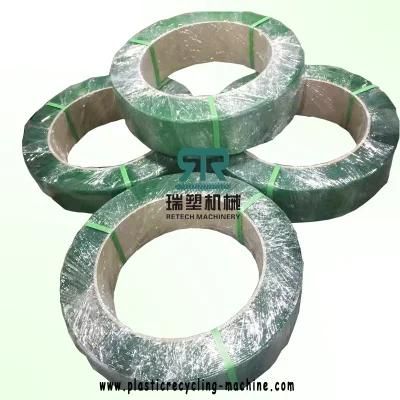

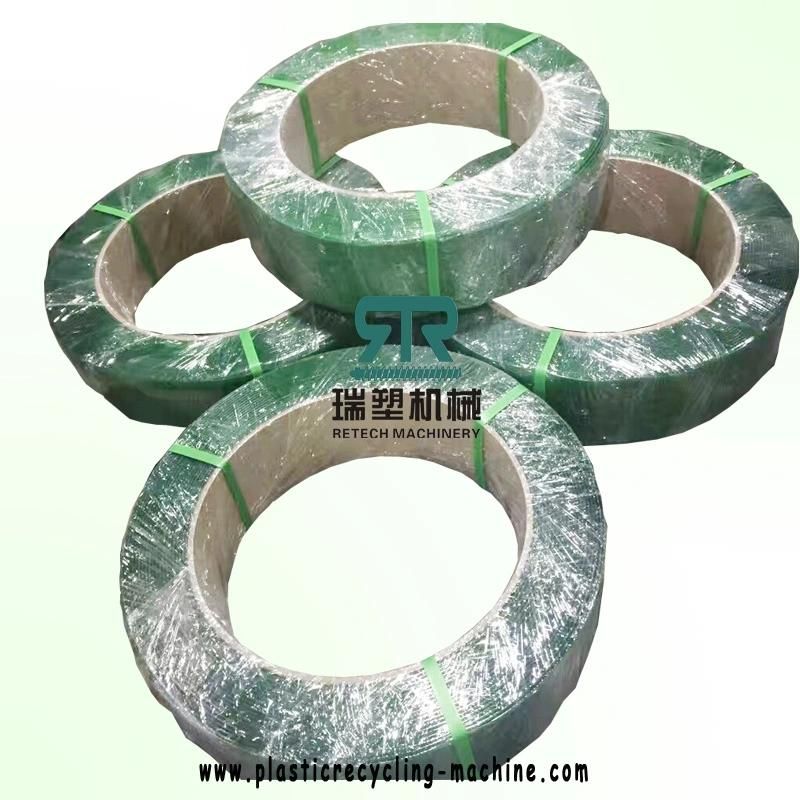

Model NO. TPSJ45~90 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Color Could Be Customized After Sale Service Engineers Available to Service Machinery Overseas Warranty 12 Months Electric Grid 3p 220V~440V 50 or 60Hz Shipping Time 60 Days Customized Yes or Not Yes Strap Qty One out of One to Four Transport Package by Wrapped Film Specification TPSJ45~TPSJ90 Trademark TopMachinery Origin China HS Code 8477209000 Production Capacity 100 Sets Per YearProduct Description

PP PET tape PET belt extruder machinery PET strapping band production plantFeatures:

PET strap is recognized a new environment protective strapping material to substitute for Steel Strap &PP Strap in the ruling international market. They are not only the aggregation of the intensity and the tenacity of steel strap, but also overcome the disadvantage of the tradition packing material such as insufficient intensity, brittle and so on. At present, they have been applied in wood, steel and so on.

Adopts advanced dehumidify dryer system. It makes sure the material humidity at 80PPM at 50PPM dew point. Meanwhile, it compact material and increase the viscidity.

Adopts closed cycle transport system after dryer to avoid contact with outside air and make sure the material drying continuously.

Extruder adopts special screw for PET. The screw has unique separate and mix property to make sure uniform plasticizing. The screw is suitable for recycled PET bottle flakes, PET mixture and original PET material. And the extruder adopts ration forced feeding to make sure the stable extruding. It makes sure the product uniform.

Produce different model product at one die and mould, adopting hydraulic screen exchanger without material leak.

Static cooling roller replaces the water cooling tank. The roller will cool the strap at the constant temperature. It improves the product's stretch intensity.

The strap after formed will be warm and anneal treated to wipe off the part stress remained after stretch. It makes molecule tropism be steady to avoid strap distortion caused by storage.

The winder adopts double work position and auto-meter. It is easy operation and convenient coil change.

Centralized electrical control, PLC self-correcting control make it is easy operate.

Mainly and Popular Models:

| Model | Capacity | Working Power | Width Range | Thickness Range |

| TPSJ75 | about 2.5Ton/day | 50~55kw/h | 12~20mm | 0.6~1.2mm |

| TPSJ90 | about 4.5Ton/day | 110~120kw/h | 12~20mm | 0.6~1.2mm |

Main Parts:

360°services:

Customer requirements →Scheme designed →confirmed by customers →order fixed →manufacturing →trial running in our factory →confirmed by customers →shipped →engineer available overseas →whole life after sales services

Contacts:

If you are interesting more details of our products, please contact with us no hesitation!

plasticmachine.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23