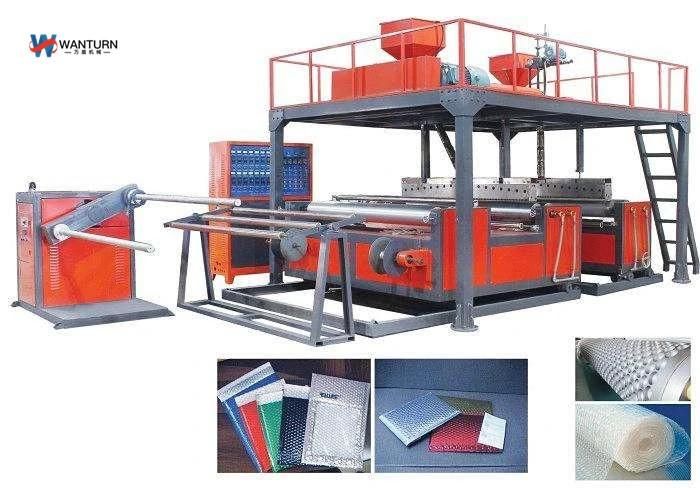

PE Compound Air Bubble Film Machine

Guangzhou Panyu District of Rock Yueli Metal Products Factory / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. WT1500 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Transport Package Film Packing or Wooden Box Packing Specification 10*6*2.5m Trademark WT Origin ChinaProduct Description

Bubble Wrap Manufacturing Machine Feature:

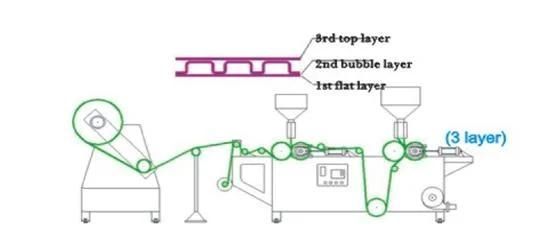

This air crew adopts the disposable shaping craft. It is our factory that draws domestic and international

advanced technology extensively, through a large number of production practices in having ordinary

equipment originally, develop, design, can produced polyethylene compound bubble (cushion) membrane

in succession. Designs science, practical. Rational in structure of the machine.

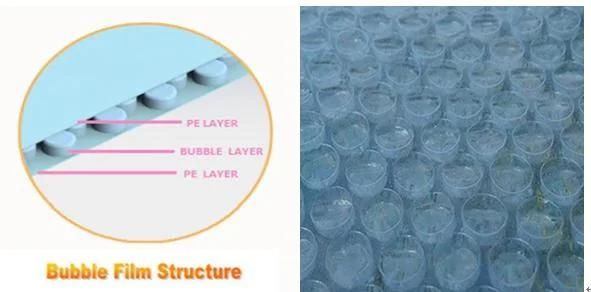

Bubble Wrap Manufacturing Machine Application:

The bubble film is made of LDPE material. It can be used for various packaging purposes such as moisture proving, dust proving, shock proving, and static prevention. It can also make into laminated films with aluminized film, foamed PE sheet, and paper are the applications of sun shading, heat insulation, and packaging.

Main Specification:

| Model | WT-1500 |

| Main and auxiliary extruder screw diameter | Φ75mm Φ60mm |

| L/D | 30:1 |

| Main and auxiliary extruder electrical power | 18.5KW 15KW |

| Width of production | 1500 mm |

| Main bubble specification | 10×3.6mm 6×3.2mm ( 25×10mm 30×10mm) |

| Output | 80-120kg/h |

| Total installed capacity | 112kw |

| Overall dimension | 7000mm×4000mm×3150mm |

| Gross weight | 6T |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23