Silver Brazed Grinding Disc for Concrete and Masonry in Your Need/Diamond Grinding Cup Wheel/Diamond Tool

Pinghu Kaixin Plastic Industry Co., Ltd. / 2022-06-27

- Manufacturing Process:Brazing

- Shape:Flat-Shaped

- Bonding Agent:Metal

- Manufacturing Technology:Brazing

- Segment No.:20

- Segment Thickness:10mm

=== Base Info ===

- Model NO.:CGDC

- Transportation:Ocean, Land, Air, Express

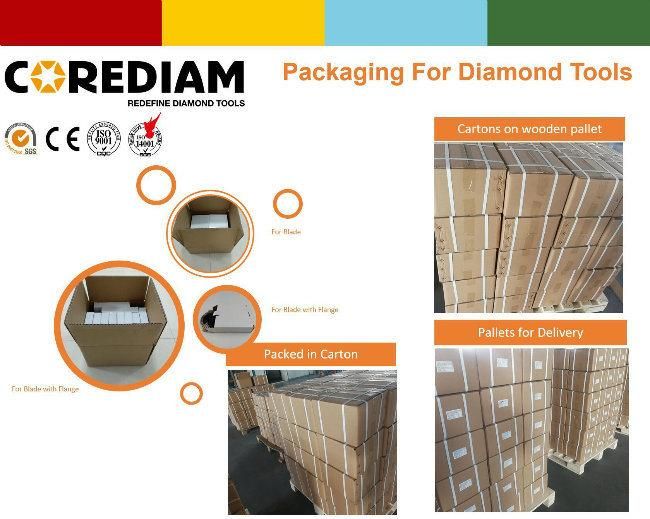

- Transport Package:Carton, Pallet

- Specification:250x10mm

- Trademark:COREDIAM

- Origin:China

- HS Code:68042190

- Production Capacity:500 Pieces,Month

=== Description ===

Diamond Grit

4.Note

To choose the right diamond floor grinding shoe and diamond grinding cup wheels from suppliers, you must know the hardness of your concrete.

Concrete can be soft, hard, abrasive, dusty and brittle etc. There are no two floors are ever the same, typically they are more abrasive when the floor is new or have a high sharp sand content. The more abrasive the floor the harder bond you will need to get the best performance out of the diamonds.

Bond - The strength of the metal binder that holds the diamond grit in the segment. Typically the harder the bond the longer the life. Soft concrete needs the hard bond, medium hard bond for medium concrete and soft bond for hard concrete.

5.Delivery time

1 week for sample order, and 2-3 weeks for batch orders.

6.Types of equipment & Testing Process

7. Corediam OME Packing & Delivery.

Besides the neutral white box package, we have the OEM finishing package such as individual blister and paper insert for the cup wheel. We can also make the package as your design, and provide package design service too.

8.Corediam introduction

Corediam Tools Co., Ltd., as a high-tech enterprise, concentrates on researching & developing, manufacturing and marketing diamond tools industry. We have the most extensive, innovative and powerful range of diamond tools for construction, stone and DIY markets. Corediam strives to be the leading professional supplier in the world by technology innovation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23