PVC Sheet Producing Mixing Mill for Calender Line

Taizhou Sumeng Grinding Wheel Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. ht Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Application Rigid/Semi-Rigid/Soft PVC Film/Sheet Size Customized Capacity Customized Transport Package Plywood Specification CE Trademark B-TRUST Origin China Production Capacity 350-4000kg/HProduct Description

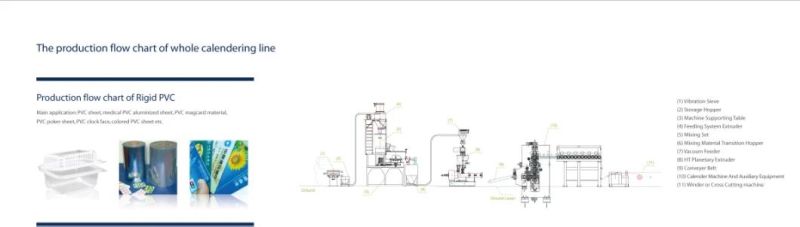

Rigid PVC Sheet Calendering Line

Rigid PVC Sheet Calendering LineMain application: vacuum forming PVC sheet, medical packaging PVC sheet, PVC magcard material,PVC poker sheet, PVC clock face, colored PVC sheet etc.

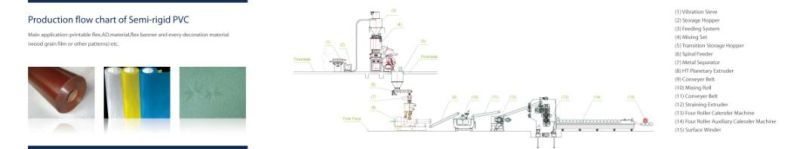

Semi-rigid PVC Sheet Calendering Line

Semi-rigid PVC Sheet Calendering LineMain application: printable flex, AD material, flex banner, decoration material(wood grain film,marble film etc.)

Soft PVC Sheet Calendering Line

Main application: various kinds of inflatable toys, raincoat material, salt film, agricultural film, packing for home textile etc.

PVC Film/Sheet Calendering line

1.Automatic Weighing System

For powder measuring&liquid measuring

Function: auto dosing, auto feeding, PLC auto control.

2.Super Mixer

Jacketed barrel,pheumatic discharging,stainless steel surface

3.Cooling Mixer

Jacketed barrel,pheumatic discharging,stainless steel surface

4.Planetary extruder

Perfect plasticizing & homogenizing quality,excelent self-cleaning screws, long service life,

electric power savings , short formula change times,maximum CaCO3 /filler plastification capacity,low

cost,competitive Product quality

5. Mixing Roll

Bearing standing:iron casting processing with lubricating holes, auto. material turnover device,adjustable air cylinder control,gyro spinning type

6.4-roll Calender machine/5-roll calender machine/6-roll calender machine

Application:high quality rigid,simi-rigid and soft PVC sheet.

Composition:body, roller unit,gap adjusting device,roller suspension & bending device,cross device,stock stop device,reduction gearbox,main rotary unit,cardan,lubrication system,oil-pressure system,bottom roller scrap take-off device,piping,power off ON-OFF

7.embossing, cooling,scrap cutting unit and platform scale

Parts of Machine:leading outlet unit,embossing wheel unit,cooling wheel unit,waste film trimming,piping

8.Dual axial type auto. center winder

Profile steel welded frame, tempering treatment, tension control system

9.AC Motor and control system

Location: calender machine and its rear segment ,main circuit switch, other circuits switch and protection circuit

10.Roller temperature control system

Temperature control: oil-type die heater,electric heating; micro-computer working system; all-in-one fail-safe, displaying and controlling entrance, exit of hot kerosene and temperature setting, with excellent functions of automatic safety protection

11.Conveyors and scrap winders

12.Die heater(heated-used cooling wheel in rear segment)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23