Fabricated Potato Chip Processing Line

Cixi Xinhua Packing Co., Ltd. / 2022-07-04

- Automatic Grade:Automatic

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Application:Chips

- Customized:Customized

=== Base Info ===

- Specification:3900mm * 600mm * 430mm

- Transport Package:Wooden Box

- Product Name:Fabricated Potato Chips Line

- Capacity:200kg,H

- Power:100kw

- Weight:25t

- Operating Mode:Automatic

- Material:Stainless Steel 304#

- Model NO.:FA200

- Trademark:Handyware

- Origin:Foshan

- HS Code:8438800000

- Production Capacity:200~300kg,H

=== Description ===

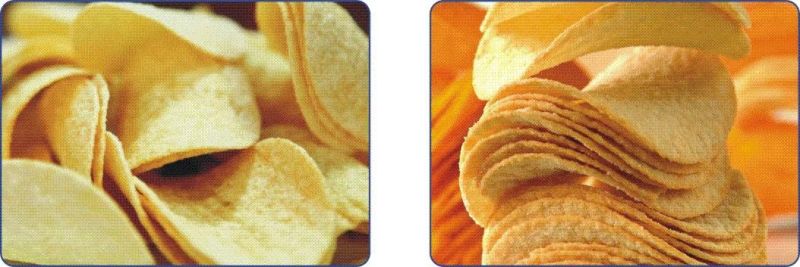

End products

Fabricated Potato Chips

Our strength

1. Excellent end product

Continuous, automated processing results in consistent, predictable end product

2. Oil cost saving

No oil discharge required if run 24/7

3. Top quality

Manufactured using high quality stainless steel 304

4. Productivity

Labour 8-9 pax(exclude packing)

Low oil wastage if run 24/7

Scrap dough recycled to reduce wastage

5. Prevent Over-cooking

Non-direct heating reduces oil rancidity

Heat exchanger used to maintain desired cooking oil temperature

6. High speed mixer

Medical grade high speed mixer uniformly mix various raw material

7. Recycle dough scrap

Dough scrap recycled and mixed with fresh material

Mixing achieved using enhanced mixer

8. Cleaner oil

Regularly circulated oil is filtered with 40 mesh filter

9. Easy to control

Central control panel to manage process parameters

Customer of Handyware Engineering

Exhibition

Patent Certificate:

Before sale services:

1. Provide initial standard machine configurations.

2.According to the clients' special requirment,offer customized and competitively priced solution. Where necessary,offer customer with options .

3.Help client design the factory and offer professional advice ,provide free drawing for the factory layout.

4.Welcome to visit our factory for machine viewing or trial.

Services during the sales:

1.Provide customer with regular production status update.

2. Invite customer for inspection of machine before delivery.

After sale services:

1.Oversea install of the equipment.

2.Provide the basic food formulation.

3.Operation/Service/Maintenance Manual: Provided in English.

4. We will provide engineers to client's factory for the installation and training . The client is required to provide accomodation,food, round-trip ticket, visa,transportation fee and engineer fee of $80 /day/engineer.

Design of capacity as per needs.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23