Carbide Rotary Files

CANGZHOU BEWIN PIPELINE CO., LTD. / 2022-06-27

- Type:Carbide Burrs

- Material:Carbide

- Usage:Metal Drilling

- Shape:Cylindrical

- Processing Methods:Cutting Tooth File

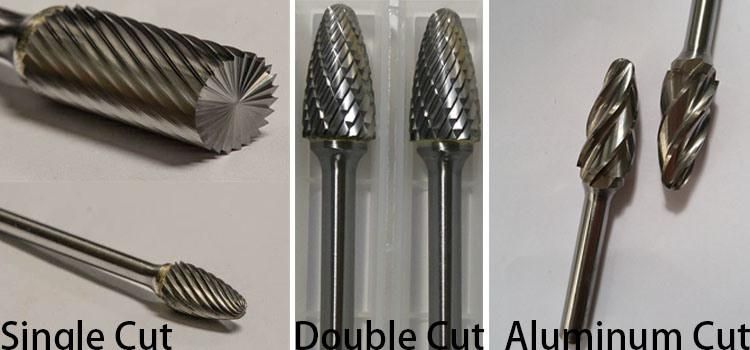

- Tooth Pattern:Bidentate Pattern

=== Base Info ===

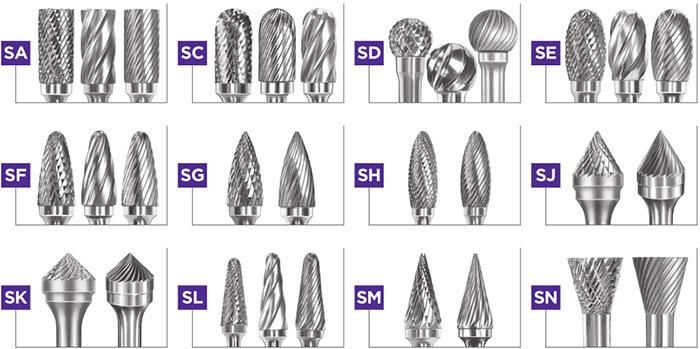

- Model NO.:SA~SN

- Section Shape:Round

- Color:Unicolor

- Customized:Non-Customized

- Condition:New

- Code:SA~Sn

- Shank:3, 6mm or 1,8", 1,4"

- Head Dia.:3mm or 1,4" ~ 25mm or 1"

- Length:70mm or 2-3,4"

- Transport Package:Plastic Box

- Specification:ISO

- Trademark:AT CARBIDE

- Origin:Chengdu, China

- HS Code:82080100

- Production Capacity:100, 000 PCS,Month

=== Description ===

Structure

Structure

13Head Shapes

Cut Types

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23