China Twin Screw Food Extruder Machine Manufacture

Ningbo DSW International Co., Ltd. / 2022-07-05

- Processing Material:Animal Raw Materials, Natural Ingredients

- Application:Pet Food, Vegetable

- Customized:Customized

- Certification:CE, ISO9001

- Power Source:Electric

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:DT70

- Material:Stainless Steel

- Electric Parts:LG ,FUJI,Omron etc

- Stainless Steel Material:304

- Controlling:Inverter

- Capacity:100-150kg,H 200-250kg,H 500kg,H,800-1000kg,H

- Extruder Types:Twin Screw

- Name:Twin Screw Food Extruder Machine

- Model No:Slg

- Industrial:380V 50Hz

- Manufacture:Jinan Datong 0086-15264102980

- Transport Package:woodencase

- Trademark:Jinan Datong Machinery Company

- Origin:JInan

- HS Code:84349000

- Production Capacity:100-1500kg,H

=== Description ===

Basic Info.

Model NO. DT70 Material Stainless Steel Electric Parts LG ,FUJI,Omron etc Stainless Steel Material 304 Controlling Inverter Capacity 100-150kg/H 200-250kg/H 500kg/H,800-1000kg/H Extruder Types Twin Screw Name Twin Screw Food Extruder Machine Model No Slg Industrial 380V 50Hz Manufacture Jinan Datong 0086-15264102980 Transport Package woodencase Trademark Jinan Datong Machinery Company Origin JInan HS Code 84349000 Production Capacity 100-1500kg/HProduct Description

1. Corn Snacks machine

2. Corn snacks machine

3. Puffed snack food machine

4. Snack food processing line

5. Cheese balll machine

6. Cheese curls processing line

7. Inflating snacks processing line

8. Leisure inflating food machine

9. Crispy snack food making machine

10. Core-filling snack food machine

1. Description of Sweet puffed corn sticks food processing line:

Cheese Curls Food Extruder Machinery adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.  2. Snacks Raw materials:

2. Snacks Raw materials:

Corn, rice, millets, wheat, oat, barley etc as ingredients. Please note that all the materials should be in powder(flour) or grits form.

3. Snacks food Products shapes:

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

4. Corn snack food line Capacity: 60-80kg/h 100-150kg/h, 200-240kg/h, 500kg/h

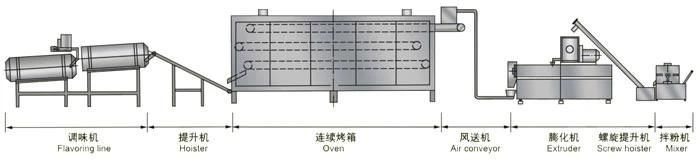

5. Snacks food extruding line Flow chart:

Grain grinder---Mixing system---Twin screw Extrusion system----Drying system----Flavoring system--Packing system

6. China standard industrial Voltage for the machine:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, We can make it according to customers' Local voltage according to different countries (400v 415v 480v...).

7. Sancks food Machines Materials:

All the Snacks food machines are made by stainless steel, this whole line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

8. Details & Features of Cheese Balls Plant:

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

9. Service & Turnkey Solution:

a. ) Consultation service before, during, and after sales;

b. ) Project planning and design service;

c. ) Debugging of equipment until everything is functional;

d. ) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e. ) Training of equipment maintenance and operating personally;

f. ) New production techniques and formulas;

g. ) Provide 1 year complete warranty and life-time maintenance service.

| SLG65-III snack machine | 70kw | 40kw | 100-150kg/h | 22000x1200x2200mm |

| SLG70-III puff snack processing line | 90kw | 50kw | 200-240kg/h | 25000x1500x2200mm |

| SLG85-III snack food extruder | 120kw | 100kw | 400-500kg/h | 30000x3500x4300mm |

| SLG90-III corn snack food production line | 135kw | 100kw | 800-1000kg/h | 30000x3500x4300mm |

| SLG65-I snack processing line | 50kw | 30kw | 60-80kg/h | 15000x1200x2200mm |

A: We are the manufacturer, which has almost 10 years of experience in this industry.

2. Q: How can I get to your company?

A: That's great you can visit our factory, welcome! You can get a flight to Jinan Airport. Our factories are just about 30 minutes drive away from Jinan Airport.We are so glad to arrange our car pick you up!

3. Q: How long is your guarantee?

A: One year(Calculated from the equipment arrives the customer's side.).

After this period we will definitely support you when needed.

You will be welcome to contact us with any problem may happened.

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer.

Or you can get local contractors to do the commissioning and we send one supervising engineer.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23