Puffed Corn Snack Food Extruder Machine Puffed Corn Snacks Making Equipment Expanded Puff ...

Heshan Jile Industrial Co., Ltd. / 2022-07-05

- Power Source:Electric

- Process:Extruder

=== Base Info ===

- Automatic Grade:Automatic

- Application:Candy, Chocolate, Popcorn, Chips, Biscuit, Donut, Breadcrumb

- Customized:Customized

- Technology:Advanced,Modern

- Performance:High Level

- Output:100-150 Kg,H

- Transport Package:Standard Mill

- Specification:304 Stainless Steel

- Trademark:MOLE

- Origin:China

- Production Capacity:10PCS,Month

=== Description ===

Basic Info.

Automatic Grade Automatic Application Candy, Chocolate, Popcorn, Chips, Biscuit, Donut, Breadcrumb Customized Customized Technology Advanced/Modern Performance High Level Output 100-150 Kg/H Transport Package Standard Mill Specification 304 Stainless Steel Trademark MOLE Origin China Production Capacity 10PCS/MonthProduct Description

Product DescriptionCorn puff snack food machine adopts corn, rice, wheat, oat, barley, etc as ingredients to make puffed snack. Through frication of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel, and flower, etc.Our extrusion machines can produce various uncoated, coated or filled cereal-based snacks - with a wide variety of recipes and shapes. corn puff snack extruder machine adopts twin-screw extrusion technology and are highly flexible. They can be easily modified to process new products such as filled products, corn chips snacks or bread crumb snacks, with just easily adding some auxiliary equipment.

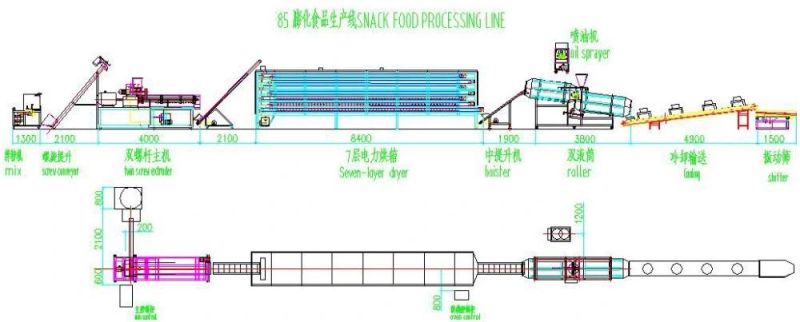

Flow chart:grinding→mixing→extruding→drying→flavoring→cooling→packaging

Flow chart diagram:Our engineer could design the layout drawing according to your dimension of the factory for the snacks food machine

Raw material:

Corn, rice, millets, wheat, oat, barley etc as ingredients. Please note that all the materials should be in powder(flour) or grits form.

Final product:

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower, and heart shape by adjusting the mold in the extruder.

Company Information

We can also provide special designing production line according to clients' special

requirements. Free formula, local installation, workshop design, machine inspection service are provided, any need will be met if inquiries.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case

(based on the customers' need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

Our Services

1. Free consultation service before, during, and after-sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free long-distance shipping management from seller's factory to named place by buyer;

5. Free maintenance and operating training personally;

6. Free new production techniques and formulas;

7. Provide 1-year complete warranty and lifetime maintenance service;

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23