Eyewear Frame Laser Repair Spot Welder Stainless Steel Laser Spot Soldering Machine

Guangzhou Jurun Trading Co., Ltd. / 2022-06-23

- Technical Class:Continuous Wave Laser

- Control:Manual

=== Base Info ===

- Model NO.:LK-SW200

- Power Density:Deep Fusion Welding

- Laser Classification:YAG Laser

- Type:Jewellery Laser Welding Machine

- Max, Laser Power:200W

- Laser Type:YAG

- Laser Wavelength:1064um

- Pulse-Width:0.5-20ms

- Pulse Energy:120j

- Pulse Frequency:0-50Hz

- Laser Welding Depth:0.1-0.8mm

- Laser Welding Area:300mm

- Sighting Positioning System:CCD,Monitor

- Cooling Method:Water Cooling

- Transport Package:Wooden Case

- Specification:1000*600*800mm

- Trademark:LK-Laser

- Origin:Shenzhen

- HS Code:8515809010

- Production Capacity:100000sets

- Package size per unit product:1500.00cm * 700.00cm * 1360.00cm

- Gross weight per unit product:210.000kg

=== Description ===

Basic Info.

Model NO. LK-SW200 Power Density Deep Fusion Welding Laser Classification YAG Laser Type Jewellery Laser Welding Machine Max, Laser Power 200W Laser Type YAG Laser Wavelength 1064um Pulse-Width 0.5-20ms Pulse Energy 120j Pulse Frequency 0-50Hz Laser Welding Depth 0.1-0.8mm Laser Welding Area 300mm Sighting Positioning System CCD/Monitor Cooling Method Water Cooling Transport Package Wooden Case Specification 1000*600*800mm Trademark LK-Laser Origin Shenzhen HS Code 8515809010 Production Capacity 100000setsPackaging & Delivery

Package size per unit product 1500.00cm * 700.00cm * 1360.00cm Gross weight per unit product 210.000kgProduct Description

eyewear frame laser repair spot welder stainless steel laser spot soldering machine

Main Features1) One key operation: one key switch, simplify the starting process , convenient use process Cumbersome Process.

2) The single chip microcomputer control regulation: the storage 50 groups commonly used welder parameters, convenient use again.

3) The energy, pulse width, frequency and light spot size can be adjusted in a large range to realize different welding effects. The parameters are adjusted by the lever in the seal cavity, which is simple and highly efficient.

4) Use the most advanced light shielding system to eliminate the irritation to eyes by light during working.

5) Able to work for 24 hours continuously; stable performance; free of maintenance in 10,000 hours.

6) Human-based design accords with ergonomics, avoiding fatigue after long time working.

Technical Parameter| Equipment type | Lk-SWS200 |

| Max.Laser Power | 200w |

| Laser Type | YAG |

| Laser Wavelength | 1064um |

| Pulse-Width(ms) | 0.5-20ms |

| Pulse Energy | 120J |

| Pulse Frequency | 0-50hz |

| Laser Welding Depth | 0.1-0.8mm |

| Laser Welding Area | 300mm |

| Size of Welding Spot | 0.2-2mm |

| Adjusting range of light spot | 1.8mm |

| Sighting Positioning system | CCD/Microscope |

| Cooling system | water cooling |

| Integrity Power | 5kw |

| Power supply | AC220VAC/380VAC+-15%/50hz/25A |

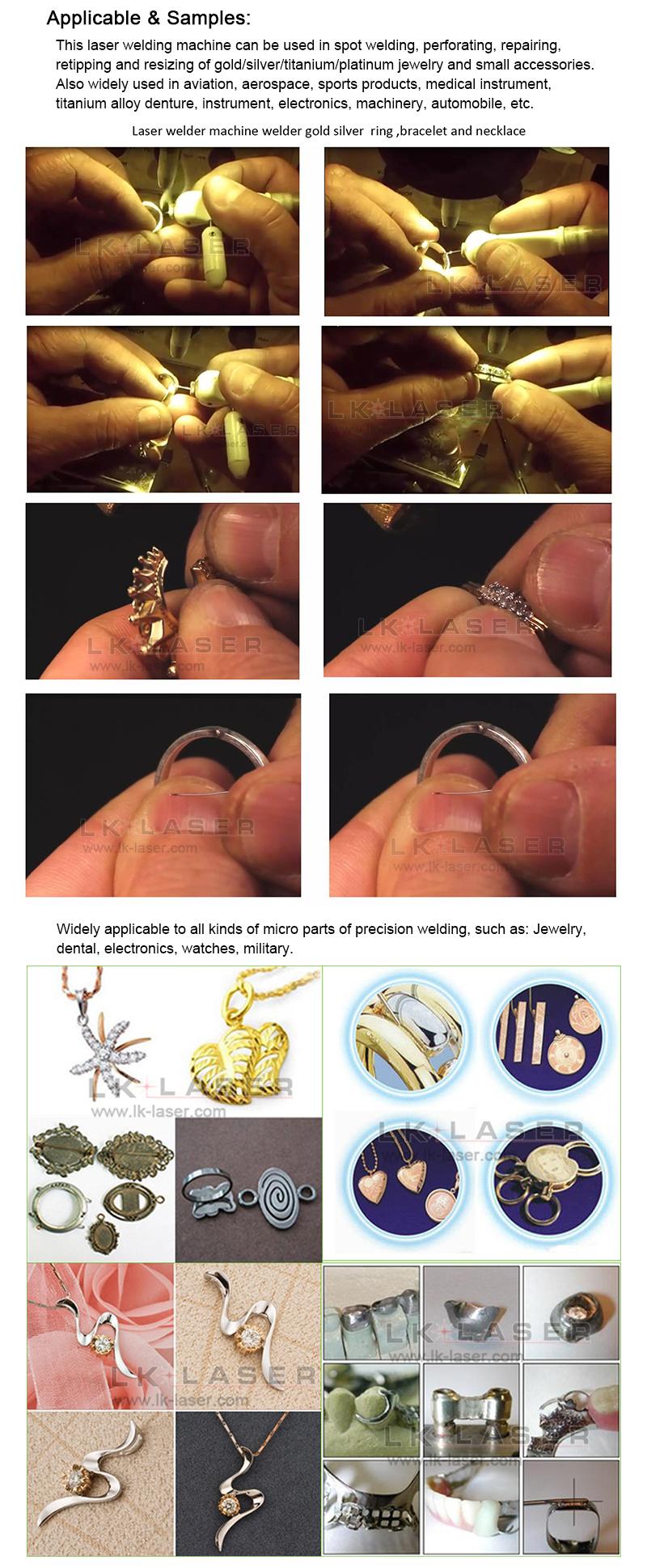

Product Application

Application Jewelry act the role of tasted fill holes, spot welder seam lines and sand holes, repair set foot part welder parts claw. Can also be used to fill sand holes and small teeth precision components such as batteries with nickel, integrated circuit leads, watches and clocks, kind, austenitic stainless in the fields of electron gun, assembly welder.Widely used in aviation, aerospace, sports products, jewelry, golf head, medical instrument, titanium alloy denture, instrument, electronics, machinery, automobile, etc, especially for the perforating of gold and silver jewelry, spot welding, repairing, inlay and welding of claw.

The welder process of heat affected zone is small Welding spot size can be adjusted freely. Solder fine, smooth, beautiful, without too much welder post-treatment. Accurate positioning Welding speed, high quality, and high efficiency environmental pollution, the solder joints. Applicable gold, silver, platinum, stainless steel, titanium and so on many kinds of metal and alloy.

FAQ

Q1: I know nothing about the fiber laser marking machine, what kind of machine I should choose?Very easy to choose.

Just tell us what you want to do using this machine. And sending us a sample picture is better.

Then we will send you a perfect solutions and suggestions.

Q2: When I get this machine, but I don't know how to use it. What should i do?

We will send you the English manual and CD video for machine using and maintaining with

machine. If you still have some doubts, we can talk by telephone or skype. Our engineer can

also be sent to your country to install or adjust machine if necessary.

Q3:if some problems happened to this machine during warranty period, what should i do?

We will supply free parts for this machine during the warranty period if machine have any

problems.We also supply free afterservice forever. So any doubts, just let us know, we will

give you solutions within 30 min.

Q4: How long is the delivery time?

For the fiber laser marking machine, the delivery time will be 2-3 days

Q5: The payment terms?

1. T/T, 30% in advance, pay the balance before delivery.

2. Through Alibaba-AliEscrow.

3. L/C

4. West Union

Q6. How about the packaging

Firstly, Packed the fiber laser machine with plastic sheet for clearing and damp proofing.

Secondly, Then put the fiber laser machine in the plywood case for safety and clashing.

Thirdly, Transport the plywood case into the container.

Our service

1. 24hours Technical support by Email or Calling.

2. English manual and CD video for machine using and maintaining.

3. Hardware: 1 years for machine,

Software: Whole life on update for free.

4.Maintenance and technological support: Whole life.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23