CNC Laser Equipment Stainless Steel Pipe Tube Fiber Laser Cutting Machine

Xuzhou Whuchan Co., Ltd / 2022-06-23

- After-sales Service:Overseas Service Available

- Warranty:1 Year

- Application:Metal Processing

- Cooling System:Water Cooling

- Technical Class:Fiber Laser

- Applicable Material:Metal

=== Base Info ===

- Model NO.:LX-K16S

- Structure Type:Desktop

- Outside Diameter:15-159mm

- Square Diameter:15*15-110*110mm

- Laser Power:1000-2000W

- Specification:9000*2610*2390mm

- Origin:Guangdong

=== Description === Our service 1. Provide proofing service before sale. Company information Foshan Longxin Laser Technology Co., Ltd.,established in 2003, is specialized in solutions for tube and pipe industries. For over 18 years,we focus on develop and produce tube cutting and tube processing machines. We have obtained High-tech enterprise certification and CE certificates. Our machines are widely used in different industries including auto parts, furniture, kitchenware,hospital beds,fitness equipment.

SCHNEIDER / France

Feature1

A.A new generation of "zero" materials for soil protection

B. LX-K16Cutting Range:Φ15-159mm15×15-110×110mm

C. Lx-k16 new high-speed three-dimensional laser pipe cutting machine

Feature2

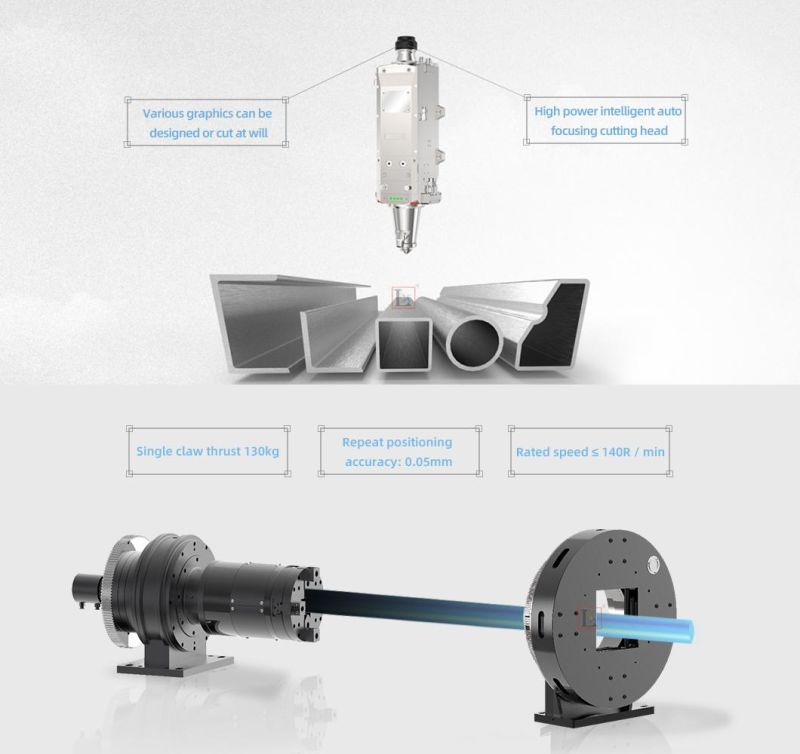

A.Multifunction cutting for round, square, rectangle and oval pipes!

B. It can straight cut, angle cut, make holes, etc.

C. Smooth and burr-free cutting.

D. Cutting loss 0.1mm/cut only.

E. Excellent cutting accuracy ±1mm.

Feature3

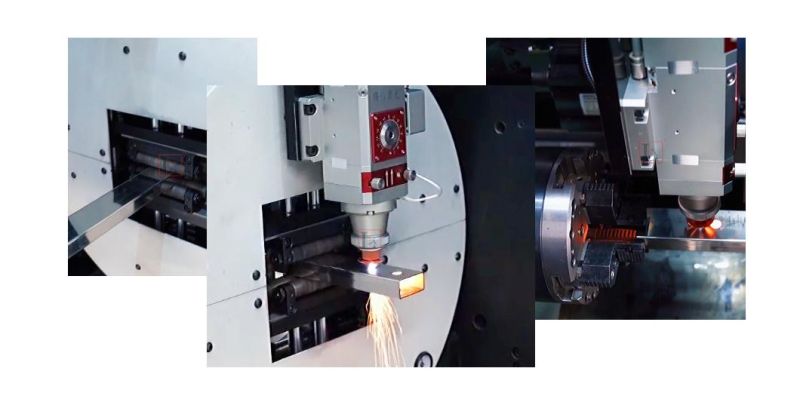

The unique movable structure of the front chuck. When cutting the tailings, the front chuck moves to the right to a reasonable po sition, and the cutting head is in the middle of the tail chuck and the front chuck. While ensuring the cutting accuracy, the tailings are controlled between 50-70mm.

Feature4

A: If the real short tailings is less than 20mm, the net profit will be saved

B. The front chuck is installed on the y-axis guide rail. When cutting mat erials, the laser head rises, and the front chuck can move according to the y-axis direction, so as to maintain the clamping of 2 chuck and mi nimize the tailings while ensuring the accuracy.

Feature5

A: The equipment adopts ospri optical fiber special laser cutting head, combined with capacitive non-contact automatic tracking system, which can adjust the best focal length and ensure the best overall cutting effect. Even if the material surface is uneven, the cutting quality can be guaranteed, and the cutting seam is flat and beautiful; The minimum cutting spacing of high-speed capacitance sensing is 0.2mm which improves the cutting performance and reduces gas consumption.

Feature6

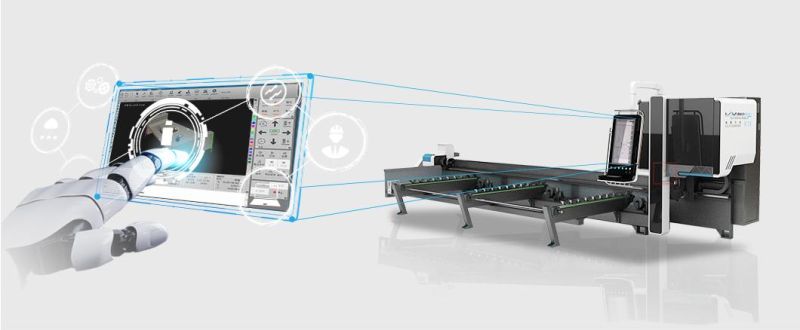

Draw any plane image on the computer, and the product can be produced immediately without mold opening. Select nesting editing software to max imize material utilization and cutting efficiency. Powerful graphic display fun ction, intuitive performance of cutting effect, online monitoring of cutting path

2. Provide free technical training after sale.

3. Provide online technical guidance, video guidance or overseas installation and maintenance services.

4. We provide the equipment one year free warranty and lifetime technical supports.

We commit to providing overall solutions for irtelligent manufacturing equipment for global users. We have fruitful experience in all kinds of metal tubes and know the cutting demands from different industries, we can offer the professional tube cutting solution to help you cut tubes in a better result.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23