High Milling Finness Duplex Flour Mill

Nanjing Zhanyi Technology Co., Ltd. / 2022-07-05

- Type:Flour Mill

- Application:Flour, All, Beans, Wheat, Rice flour

- Voltage:380V

- Appearance:Duplex

- Press Materials:Wheat,Corn,Grain and etc.

- Press Series:Fourth

=== Base Info ===

- Model NO.:FMFJ2580

- Condition:New

- Customized:Customized

- Capacity:1 T,H

- Quality:European Standard

- Warranty:1 Year

- Installation:Engineer Will Be Sent for Installation

- Usage:Grind Grains

- Supply Type:Manufacturer

- Processing:Project Cleaning Milling Packing

- Processing Type:Grain Processing Equipment

- Transport Package:Seaworthy Wood Case

- Specification:CE, ISO, SGS

- Trademark:HNLY

- Origin:Henan Zhengzhou

- HS Code:8437800000

- Production Capacity:8000 Sets,Year

=== Description ===

Basic Info.

Model NO. FMFJ2580 Condition New Customized Customized Capacity 1 T/H Quality European Standard Warranty 1 Year Installation Engineer Will Be Sent for Installation Usage Grind Grains Supply Type Manufacturer Processing Project Cleaning Milling Packing Processing Type Grain Processing Equipment Transport Package Seaworthy Wood Case Specification CE, ISO, SGS Trademark HNLY Origin Henan Zhengzhou HS Code 8437800000 Production Capacity 8000 Sets/YearProduct Description

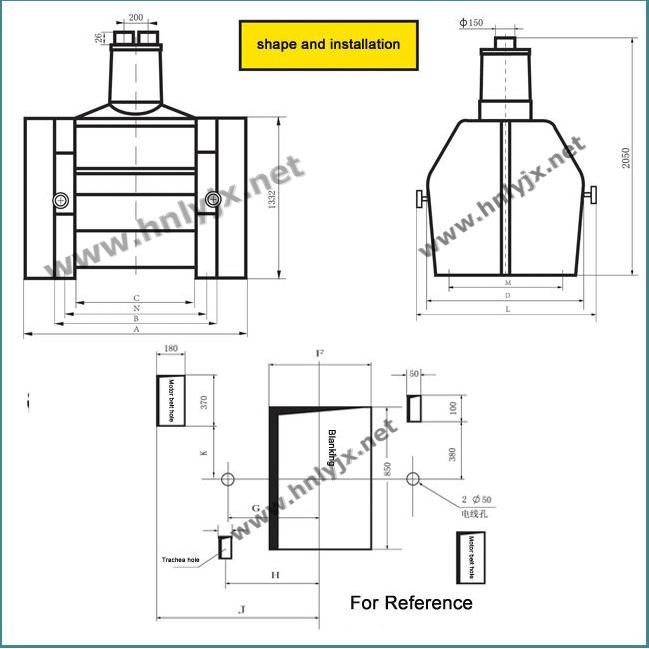

high milling finness Duplex flour millDuplex mill is the main equipment of wheat flour mills, which is adjusted according to the the coming material's characteristics. Clutch brake from the Mill grinding roll and operating of feed rolls are manually controlled.

| parameter model | output (t/h) | power(KW) | weight(Kg) | Dimension(mm) |

| FMFJ2540 | 1 | 5.5×2 | 1100 | 1300×1360×1800 |

| FMFJ2550 | 1.5 | 7.5×2 | 1500 | 1300×1460×1800 |

| FMFJ2560 | 2.5 | 11×2 | 2100 | 1300×1560×1800 |

| FMFJ2580 | 5 | 22×2 | 2650 | 1300×1760×1800 |

Good service:

We provide a turnkey project of our machienry, including special design, installation, commissioning ,training workers Life-long after-sales service.

All of our equipment to contain one year free spare parts, and Quality guarantee period of one year.

The process of flour milling:

The process of flour milling (from corn to milled into corn flour) usually consists of the following:

1. corn storage (silos, or warehouse) ------

2. cleaning system (sifter, destoner, seprater, magnet, scourer, etc) -

3. dampening (dampener, conditioning silos, etc) 4. milling system (roller mill, plansifter, purifier, impact detacher, etc.)

5. Flour pressure and blending system (if need) ----------

6. flour packing and stacking

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23