Twin Screw Extruders for The Powder Coating

Hebei Botou Safety Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. TSX SLJ Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Capacity 0.2-1800kg/H Series Tsx, Slj Transport Package Pallet/Case Trademark TOPSUN Origin Yantai, China HS Code 8474 Production Capacity 10 PCS/MonthProduct Description

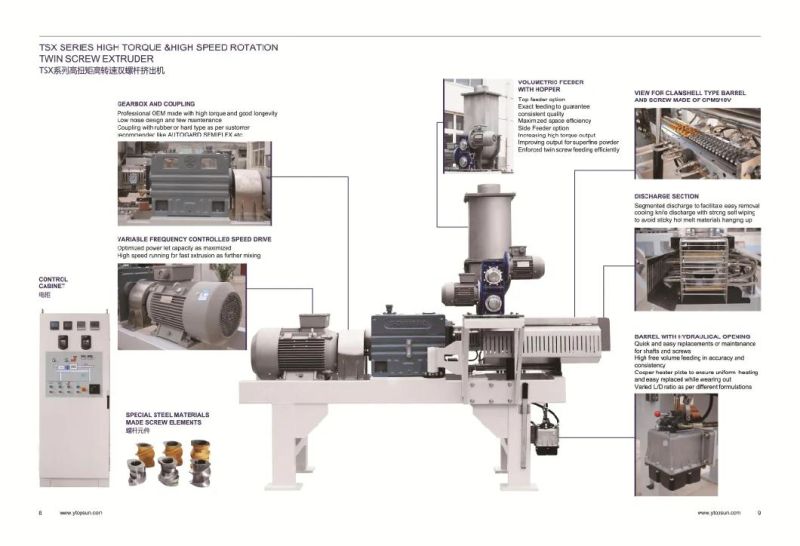

High torque & High Speed Rotation Twin-Screw Extruder:Website: ytopsun.en.made-in-china.com, ytopsun.en.made-in-china.com

Main Features:

*Full Gearbox from professional OEM maker, low noise, durable longevity

*High screw speed, high shearing, quick discharge

*Independent lube oil cooling system design

*Torque limiter to protect the drive train

*Suitable for reclaim powder, special powder production

*Split design of barrel and liner inserts for easy cleaning and maintainence

*Top & Side feeding options

*Other features same as conventional type extruder

Technical Parameters:

| Model | Capacity (kg/h) | Screw Diameter (mm) | Screw Length (mm) | Screw Speed (r/min) | Main Motor (kw) | Feeder Motor (kw) | Heating Power (kw) | Overall Dimensions (mm) |

| TSX-40 | 80-260 | 40 | 16D | 0-800 | 11/15/18.5 | 0.55 | 8 | 1850*700*1750 |

| TSX-52 | 150-450 | 52 | 16D | 0-800 | 22/30/37 | 0.75 | 10 | 2700*900*2200 |

| TSX-65 | 400-1000 | 65 | 16D | 0-800 | 45/55/75 | 1.1 | 12 | 2900*1000*2400 |

| TSX-75 | 800-1200 | 75 | 16D | 0-800 | 75/90 | 1.5 | 16 | 3100*1200*2500 |

| TSX-85 | 1200-1800 | 85 | 16D | 0-800 | 90/110 | 2.2 | 20 | 3700*1500*2900 |

Conventional Type Co-Rotation Parallel Twin Screw Extruder

Features:

*Strong shearing, easy cleaning

*Accurate auto temperature control, high cooling & heating exchagne

*Hinged clamshell type barrel opening, segmented liners for easy replacing and cost saving

*Feeder easy assembly & disassembly, inner structure to avoid agglomeration

*Configurable screw applied for defferent powder formulas

*Screw and barrel adopt special materials like Cr12MoV, CPM, etc., high wearing resisting

*Quite gearbox with low noise dB level

*Torque limiter to protect the drive train

*Low energy consumption

Technical Parameters:

| Model | Capacity (kg/h) | Screw Diameter (mm) | Screw Length | Screw Speed (r/min) | Main Motor (kw) | Feeder Motor (kw) | Heating Power (kw) | Overall Dimensions (mm) |

| SLJ-40 | 80-220 | 40 | 16D | 0-500 | 11/15/18.5 | 0.55 | 4 | 1800*600*1700 |

| SLJ-50 | 150-300 | 50 | 16D | 0-500 | 22/30 | 0.75 | 8 | 2600*700*2000 |

| SLJ-55 | 300-400 | 55 | 16D | 0-500 | 30/37 | 0.75 | 8 | 2700*900*2300 |

| SLJ-60 | 400-600 | 60 | 16D | 0-500 | 45 | 1.1 | 12 | 2750*1000*2350 |

| SLJ-75 | 600-800 | 75 | 16D | 0-500 | 55 | 1.5 | 12 | 2900*1100*2400 |

| SLJ-80 | 800-1200 | 80 | 16D | 0-500 | 75/90 | 2.2 | 20 | 3700*800*2800 |

Technical Parameters (Lab Type):

| Model | Capacity (kg/h) | Screw Diameter (mm) | Screw Length | Screw Speed (r/min) | Main Motor (kw) | Feeder Motor (kw) | Heating Power (kw) | Overall Dimensions (mm) |

| TSX-20 | 0.2-10 | 22 | 16D | 0-600 | 2.2-4 | 0.1 | 2 | 1600*300*850 |

| SLJ-30 | 1-30 | 30 | 16D | 0-500 | 3-5.5 | 0.18 | 3.2 | 1430*550*1300 |

| SLJ-32 | 40-80 | 32 | 16D | 0-500 | 7.5/11 | 0.25 | 3.2 | 1600*500*1500 |

Company:

Dongsun is a leading manufacturer in China of Powder Coating Production Equipments, i.e. Mixers, Extruders, Cooling Belt and Air Classifier Mill. We inherit 30 years of experiences in this industry and have exported to nearly 30 countries and regions in the past 10 years, and win widely good reputations.

We passed CE certification approval and ATEX explosion resistant test, etc. international standards, we do know how to meet the diversified and customized made requests of our customers.

Our everlasting business philosophy: consistant quality, effective communication, responsible service.

High torque & High Speed Rotation Twin-Screw Extruder:

1. Main Features:

*Full Gearbox from professional OEM maker, low noise, durable longevity

*High screw speed, high shearing, quick discharge

*Independent lube oil cooling system design

*Torque limiter to protect the drive train

*Suitable for reclaim powder, special powder production

*Split design of barrel and liner inserts for easy cleaning and maintenance

*Top & Side feeding options

*Other features same as conventional type extruder

2. Technical Parameters:

| Model | Capacity (kg/h) | Screw Diameter (mm) | Screw Length (mm) | Screw Speed (r/min) | Main Motor (kw) | Feeder Motor (kw) | Heating Power (kw) | Overall Dimensions (mm) |

| TSX-40 | 80-260 | 40 | 16D | 0-800 | 11/15/18.5 | 0.55 | 8 | 1850*700*1750 |

| TSX-52 | 150-450 | 52 | 16D | 0-800 | 22/30/37 | 0.75 | 10 | 2700*900*2200 |

| TSX-65 | 400-1000 | 65 | 16D | 0-800 | 45/55/75 | 1.1 | 12 | 2900*1000*2400 |

| TSX-75 | 800-1200 | 75 | 16D | 0-800 | 75/90 | 1.5 | 16 | 3100*1200*2500 |

| TSX-85 | 1200-1800 | 85 | 16D | 0-800 | 90/110 | 2.2 | 20 | 3700*1500*2900 |

3. Conventional Type Co-Rotation Parallel Twin Screw Extruder

4. Features:

*Strong shearing, easy cleaning

*Accurate auto temperature control, high cooling & heating exchagne

*Hinged clamshell type barrel opening, segmented liners for easy replacing and cost saving

*Feeder easy assembly & disassembly, inner structure to avoid agglomeration

*Configurable screw applied for different powder formulas

*Screw and barrel adopt special materials like Cr12MoV, CPM, etc., high wearing resisting

*Quite gearbox with low noise dB level

*Torque limiter to protect the drive train

*Low energy consumption

5. Technical Parameters:

| Model | Capacity (kg/h) | Screw Diameter (mm) | Screw Length | Screw Speed (r/min) | Main Motor (kw) | Feeder Motor (kw) | Heating Power (kw) | Overall Dimensions (mm) |

| SLJ-40 | 80-220 | 40 | 16D | 0-500 | 11/15/18.5 | 0.55 | 4 | 1800*600*1700 |

| SLJ-50 | 150-300 | 50 | 16D | 0-500 | 22/30 | 0.75 | 8 | 2600*700*2000 |

| SLJ-55 | 300-400 | 55 | 16D | 0-500 | 30/37 | 0.75 | 8 | 2700*900*2300 |

| SLJ-60 | 400-600 | 60 | 16D | 0-500 | 45 | 1.1 | 12 | 2750*1000*2350 |

| SLJ-75 | 600-800 | 75 | 16D | 0-500 | 55 | 1.5 | 12 | 2900*1100*2400 |

| SLJ-80 | 800-1200 | 80 | 16D | 0-500 | 75/90 | 2.2 | 20 | 3700*800*2800 |

6. Technical Parameters (Lab Type):

| Model | Capacity (kg/h) | Screw Diameter (mm) | Screw Length | Screw Speed (r/min) | Main Motor (kw) | Feeder Motor (kw) | Heating Power (kw) | Overall Dimensions (mm) |

| TSX-20 | 0.2-10 | 22 | 16D | 0-600 | 2.2-4 | 0.1 | 2 | 1600*300*850 |

| SLJ-30 | 1-30 | 30 | 16D | 0-500 | 3-5.5 | 0.18 | 3.2 | 1430*550*1300 |

| SLJ-32 | 40-80 | 32 | 16D | 0-500 | 7.5/11 | 0.25 | 3.2 | 1600*500*1500 |

7. Company:

Dongsun is a leading manufacturer in China of Powder Coating Production Equipments, i.e. Mixers, Extruders, Cooling Belt and Air Classifier Mill. We inherit 30 years of experiences in this industry and have exported to nearly 30 countries and regions in the past 10 years, and win widely good reputations.

We passed CE certification approval and ATEX explosion resistant test, etc. international standards; we do know how to meet the diversified and customized made requests of our customers.

Our everlasting business philosophy: consistant quality, effective communication, responsible service.

8. Why choosing us?

Our boss has worked in this industry for more than 13 years.

Our vice GM has worked in this industry for more than 20 years.

Our technical manager has worked in this industry for more than 7 years.

Our production manager has worked in this industry for more than 8 years.

We have an excellent team. We are experienced, excellent, friendly and responsible, with a view to long term cooperation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23