2021 High-Tech Professional Lollipop Candy Machine with Depositing Production Line

Milesun Rubber & Plastic Technology Co., Ltd. / 2022-07-04

- After-sales Service:Field Installation, Commissioning and Training

- Warranty:One Year

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:SE150

- Application:Candy

- Customized:Customized

- Function:Lollipop Making

- Material:Stainless Steel and Carbon Steel

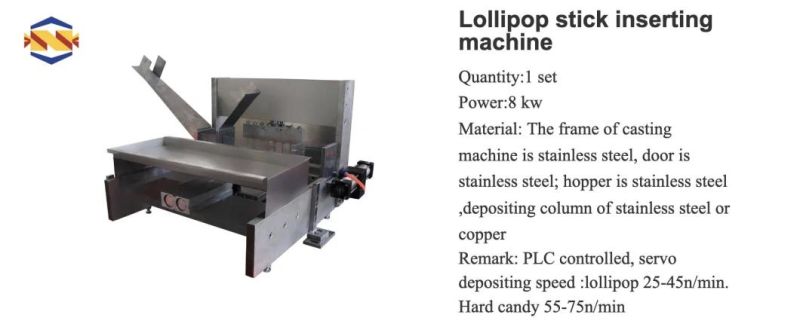

- Control Manner:PLC Controlled

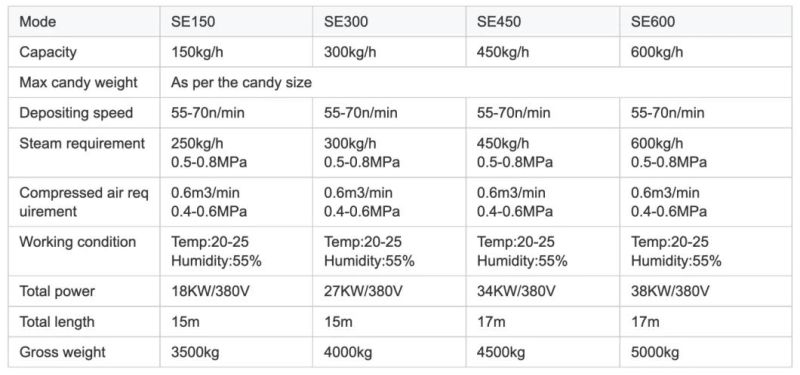

- Capacity:150kg,H---600kg,H

- Total Length:17m---22m

- Main Markets:North America, MID East, India, etc.

- Transport Package:Wooden Package

- Specification:2300*1650*2100mm

- Trademark:SIEN

- Origin:Shanghai

- HS Code:8438200000

- Production Capacity:1 Set,Month

=== Description ===

Basic Info.

Model NO. SE150 Application Candy Customized Customized Function Lollipop Making Material Stainless Steel and Carbon Steel Control Manner PLC Controlled Capacity 150kg/H---600kg/H Total Length 17m---22m Main Markets North America, MID East, India, etc. Transport Package Wooden Package Specification 2300*1650*2100mm Trademark SIEN Origin Shanghai HS Code 8438200000 Production Capacity 1 Set/MonthProduct Description

2021 High-Tech Professional Lollipop Candy Machine with Depositing Production LineThe lollipop depositing line is designed based on the hard candy depositing line.With more than 20 years candy depositor fabricating experience,the 4th generation SE series lollipop depositing line is developed on the base of the 3nd generation machine.It is an advanced equipment which can continuously produce various kinds of lollipop under a strict sanitary condition.It is not only an ideal equipment which can produce products of good quality with the cutting down of labour and the space needed,but also helps to pass the GMP,HACCP

With more than 20 years candy depositor fabricating experience,the 4th generation GD series lollipop depositing line is developed on the basis of the 3nd generation machine.It is an advanced equipment which can continuously produce various kinds of lollipop under a strict sanitary condition.

Sugar Melting Pot: For melting sugar material and keeping temperature.

Gear Pump: To transfer the mixed materials into syrup storage tank.

Syrup Storage Tank: For Storing syrup and Filtering pure syrup

The machine is equipped with the automatic rod system developed by thun machine, which can realize full automatic operation.

The whole production line is manufactured according to the food GMP standard, which meets the food hygiene requirements

Replace the mold and parts of the lollipop and hard sugar pouring production line

Main Features

1. Automatic control for alternated process of vaccum cooking and mixing;

2. An unique design of mixing system guarantees a high quality product;

3. The production capacity can reach 300kg/h;

4. Sanitary structure;

5. Automatic process control synchronized with central-filling /extruding/rope sizing; 6. Chain style die-forming for different shapes of candy;

7. Stainless steel net conveyor and cooling system guarantees the quality of the final product;

8. Soft candy,central-filling soft candy,toffee candy and ect.,can be made

Deposited hard candy machine flowchart:

Deposited hard candy machine flowchart:Raw material dissolving→Transporting→Storage

→Preheating→Microfilm cooking→Discharging→Mixing with flavor and color→Depositing

→Cooling→Demoulding→Conveying→Packing→Final product

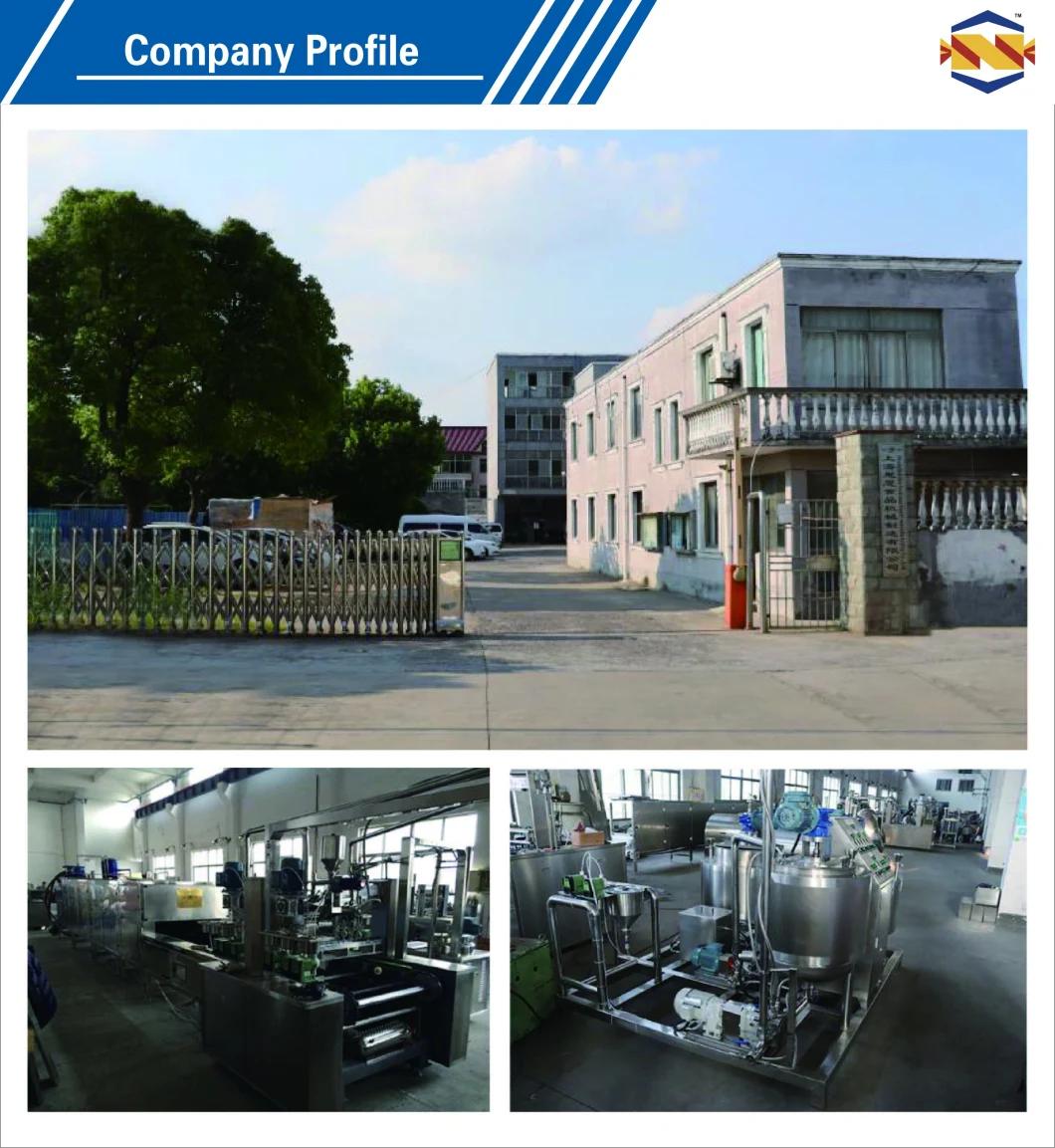

Shanghai SIEN Food Machinery Manufacturing Co., Ltd. is a professional food machinery and packaging equipment manufacturing enterprise which located in Shanghai Fengxian industrial zone food machinery base.

We have more than 37 kinds of products to meet the requirements of our customers. Our main products include candy, cookies, biscuits,bread, pie, chocolate complete sets of equipment, automatic wafer production line of various types of candy cooking , all kinds of boiled sweets, other types of inflatable equipment and supporting packing machines. Also we have attained intellectual property rights for our self-developed products.

The company integrates development, manufacturing, sales and after-sales service. We can provide a whole set of solutions including installation, commissioning, process recipe, personnel training and facility layout planning and other services.

The company has strong technical strength, sophisticated equipment and advanced technology. Since its establishment, the company has gathered outstanding scientific and technological talents and invested heavily in talent introduction and product development and improvement to continuously upgrade the products: PLC, human-machine interface and automatic control make the products more perfect and greatly narrow the gap with foreign products.

Our products sell well all over the country and are exported to Russia, the Middle East, Central , South Asia, South America and other countries and regions.

We will give back to the support and trust of new and old customers all over the world with quality products, efficient and professional sales service.

Company advantages

- We have our own factory equipped with professional technical team to develop and improve machines independently.

- We have a professional sales team, familiar with the whole process of international trade.

- We are the only factory in China that has done the maximum capacity candy production line

- Our company has a wide range of products , candy machine, biscuit machine, chocolate machine, cake machine and other food machinery can be provided

- Our company's products have a broad market, and exported to Europe, America, Southeast Asia, the Middle East and other regions

Product advantages

- All machines can be customized.

- The machine is controlled by servo with stable performance

- The machine is equipped with touch screen, easy to operate

- All machine parts are processed by CNC technology with stable quality

- Electrical appliances adopt international brands, quality is guaranteed

Company services

1.Provide 24 hours technical support,Permanent guarantee of the product in or beyond the guarantee period. Quick response to customers' reporting of the failure of machine. "Recover the production" is priority.

2.Providing expect for the instruction of install and debug of the equipment

3.Providing specialized training for the workers, through which they could have a better grasp of the operation and fixing skill of a machine

4.Providing accessories of equipment permanently at a reasonable price and quick delivery.

5.Can provide you with a whole candy production line and technology solution.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23