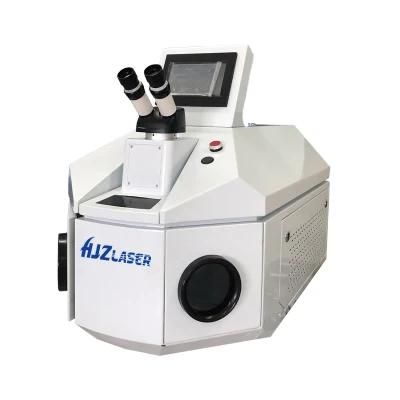

200W Jewelry Welding Machine with YAG Spot Welding for Jewelry Dental Electronic Elements Welding

Emoer Industry Limited / 2022-06-23

- After-sales Service:24hrs

- Warranty:2 Years

- Application:Electronic Industry, Automotive Industry, Manufacturing Industry

- Technical Class:Pulse Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

=== Base Info ===

- Laser Classification:Optical Fiber Laser

- Type:Optical Fiber Transmission Laser Welding Machine

- Terms:Technical Parameters

- Max. Output Power:200W

- Pulse Width:1-5ms

- Wavelength:1064nm

- Software:Rdcam

- Package:Standard Crate for Export

- Laser Welding Pool:0.1mm

- Laser Welder:Gold Laser Welding Machine

- Power Supply:220V,50,60Hz

- Welding Depth:0.08-2.5mm

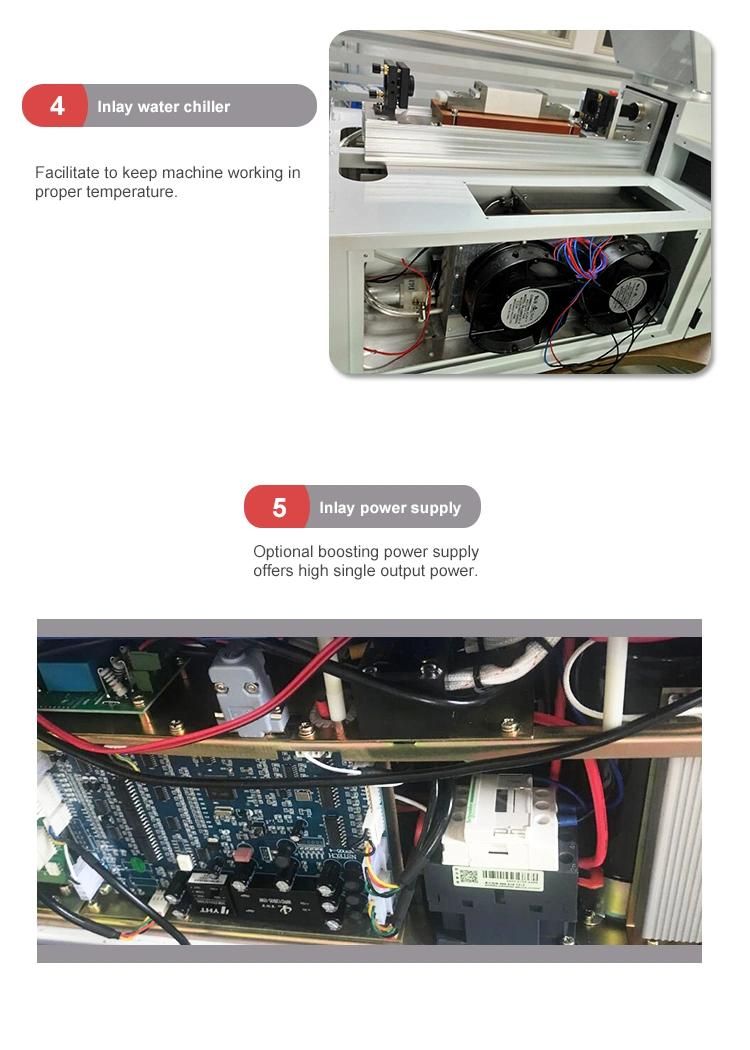

- Cooling System:Water Cooling

- Pulse Frequency:0.1-100Hz

- Welding Area:300*300mm,2500*1500mm

- Welding Materials:Jewellry Welding

- Transport Package:Standard Plywood Packing for Export

- Specification:840*450*500mm

- Trademark:HJZ

- Origin:Wuhan, China

- HS Code:84572000

- Production Capacity:300sets,Month

=== Description ===

Basic Info.

Laser Classification Optical Fiber Laser Type Optical Fiber Transmission Laser Welding Machine Terms Technical Parameters Max. Output Power 200W Pulse Width 1-5ms Wavelength 1064nm Software Rdcam Package Standard Crate for Export Laser Welding Pool 0.1mm Laser Welder Gold Laser Welding Machine Power Supply 220V/50/60Hz Welding Depth 0.08-2.5mm Cooling System Water Cooling Pulse Frequency 0.1-100Hz Welding Area 300*300mm/2500*1500mm Welding Materials Jewellry Welding Transport Package Standard Plywood Packing for Export Specification 840*450*500mm Trademark HJZ Origin Wuhan, China HS Code 84572000 Production Capacity 300sets/MonthProduct Description

200W Jewelry Welding Machine with YAG Spot Welding for Jewelry Dental Electronic Elements Welding

Technical data

| Model | HJZ-JW200 |

| Max.Output | 200W |

| Wavelength | 1604nm |

| Laser Type | Nd. YAG |

| Welding Depth | ≤3mm |

| Pulse Frequency | 0-40HZ |

| Laser Spot Size | 0.2-3mm |

| Checking System: | Microscope |

| Protective Gas | Argon |

| Output Focal Length | 80mmm---200mm |

| Holistic Power | 6KW |

| Power Supply | 220V/50HZ/15A |

| Flow valve | Flow range: 10~50l/min |

| Level control | Liquid level control instrument |

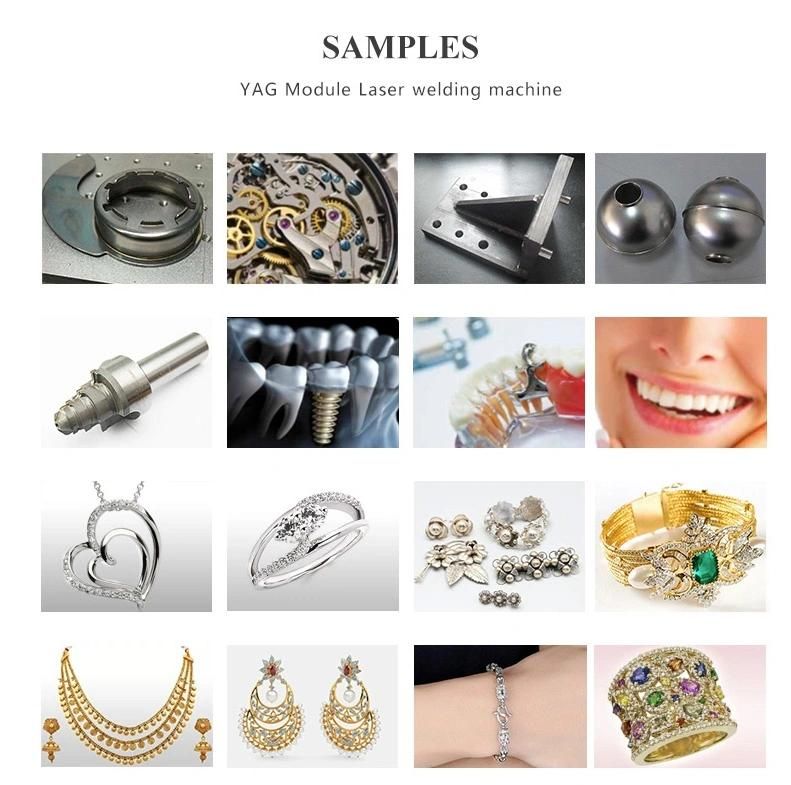

This welder is specially developed for laser welding of jewelry used in perforating and spot welding of gold and silver jewelry. The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts.

Advantages:

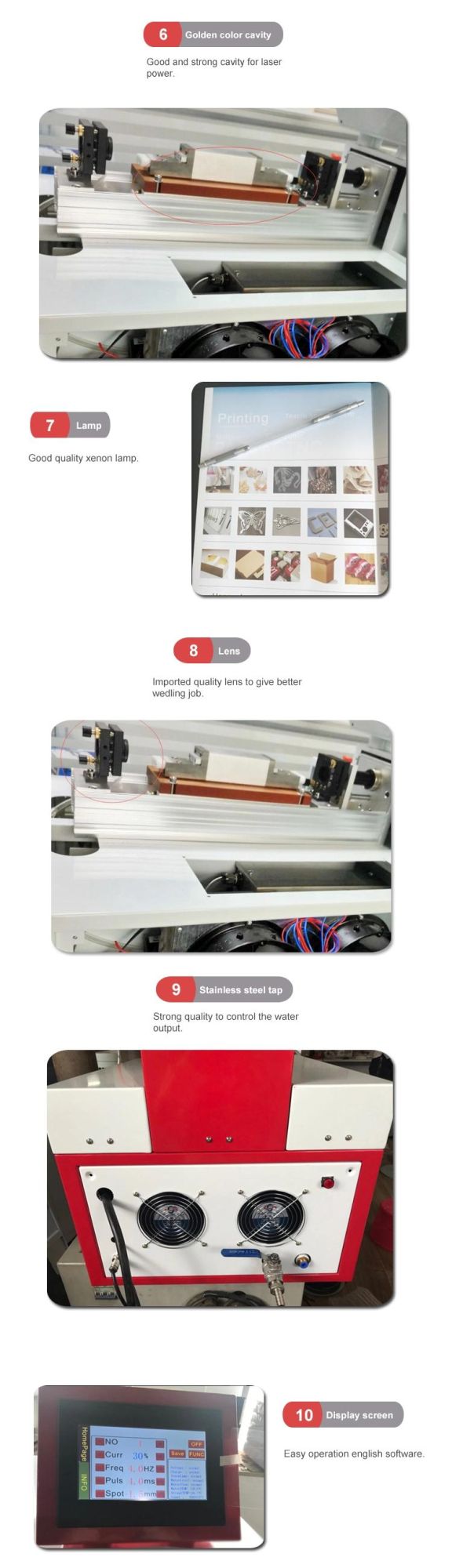

1. The energy, pulse width, frequency and light spot size can be adjusted in a large range to realize different welding effects. The parameters are adjusted by the lever in the seal cavity, which is simple and highly efficient.

2. Ceramic converging cavity is imported from the Britain. It is corrosion resistant and high temperature resistant, and has 8-10 years service life. The life of xenon lamp is more than 8 million times.

3. Use the most advanced light shielding system to eliminate the irritation to eyes by light during working.

4. Able to work for 24 hours continuously; stable performance; free of maintenance in 10,000 hours.

5. Human-based design accords with ergonomics, avoiding fatigue after long time working.

Export Wooden package

Application areas:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industries.

OEM Service

1.Customized and OEM orders are welcome due to our aboundant experiences.

All the OEM service are free,customer only need to provide us with your logo

drawing,function requirements,colors etc.

2. No MOQ required

Privacy

None of your personally identifiable information will be disclosed or shared

with any third parties.

Payment

1.30% deposit in advance, 70% balance before shipment

2.Irrevocable L/C at sight

Applicable Fields & Materials:

The machine is widely applied in electronic and communication area, it can mark on multifarious parts of autos,

hardware, apparatus, sanitation, plastic surface, lood packaging, jewelry, exact instrument etc. It is suitable to do legion domanial

figure and literal marking

Warranty & Service

Pre-sale service:

1) According to customers demands, provide relevant technical guidance.

2) Assist customers to design and make laser engraving/cutting solutions considering technical feasibility.

3) Provide equipment demonstration for customers to investigate, make samples and do test, etc.

After-sale service:

1) 1 year warranty for laser metal cutting machine;

2) Offer lifelong repair;

3) Engineers available to service machinery overseas.

4) Multi language service;

5) Offer 24 - hour technical support.

Training can be processed in the following ways:

1) Workers of customers can come to our factory in Wuhan, China to get the most professional hand-by-hand training.

2) We can send engineers to customers' country and do training for workers in customers' target factory. However, tickets and daily consumption like food and accommodation should be afforded by customers.

3) Remote training through Internet tools like Team-viewer, Skype and other instant communication software.

Guarantee:

We offer free Two-year warranty and durable maintenance&repair support for the purchased machines. Within the warranty time, we are responsible for the cost-free repair once the equipment fail or the machines break down(except human factor and force majeure causes) and we shall offer the replacement parts for free(except consumed parts). During the non-warranty time, we just charge the flat cost based on actual cost of repair.

Applicable Fields & Materials:

The machine is widely applied in the fine engraving, cutting and hollowing out on nonmetals with all kinds of characters, graphs, images, trademarks and so on.

*Handcraft industry. Plywood, Glass, Marble, Density board, Gifts, Trophy, Marks, Key chains.

*Furniture, Wood, Bamboo, MDF, Home textile, Seat Cushions, Ceramic.

*Advertising industry, Advertising plate, Acrylic, Plastic, PVC, Signs.

*Garment, Jeans, Leather, Chemical leather, Shoes material.

*Decoration, Paper Board, Organic glass, Vases,Derma.

*Model manufacturing.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23