150kgs Automatic Fruit and Vegetables Vacuum Frying Machine

AnHui Kayuen DE Glassware Co., Ltd. / 2022-07-05

- After-sales Service:Lifetime Warranty

- Warranty:12 Months for Free

- Type:Dryer

- Voltage:380V

- Power:19kw

- Customized:Customized

=== Base Info ===

- Model NO.:LW-150

- Function:Food Machine

- Name:Fruit Vacuum Frying Machine

- Use:Food Dehydration Machine

- Model:Lw-150

- Feeding:150kgs Per Batch

- Material:304 Stainless Steel

- Steam Pressure:0.3MPa

- Vacuum Degree:-0.098MPa

- Work Temperature:70-120

- Control Type:Microcomputer Automatic Control

- De-Oil Type:Built in Deoiling

- De-Oil Speed:320r,Min

- Transport Package:Wooden Box

- Specification:4400*3700*3800mm

- Trademark:LEWAVE

- Origin:China

- HS Code:841981

- Production Capacity:200kgs Per Day

=== Description ===

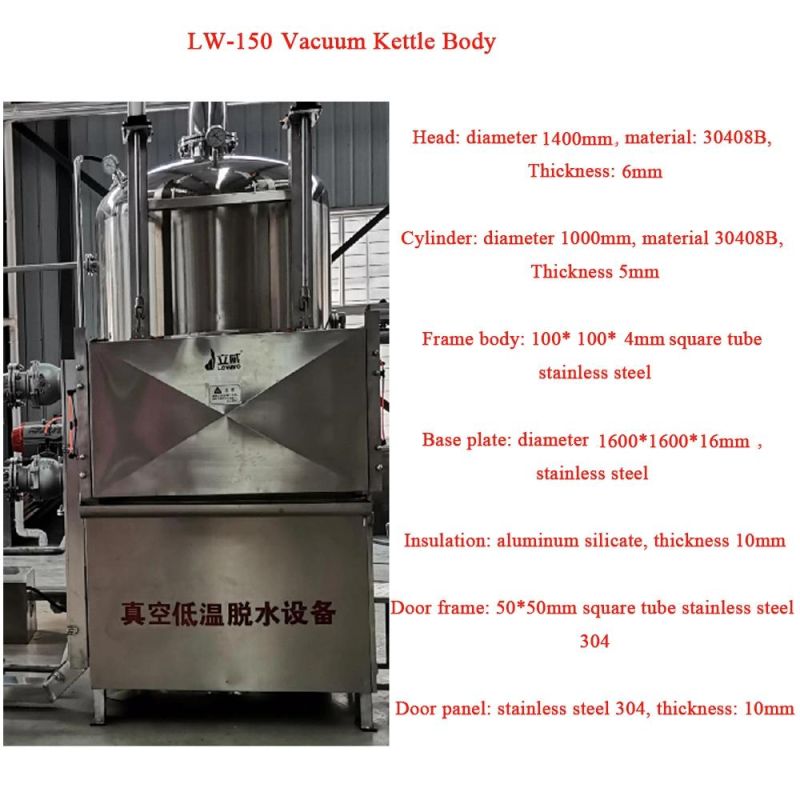

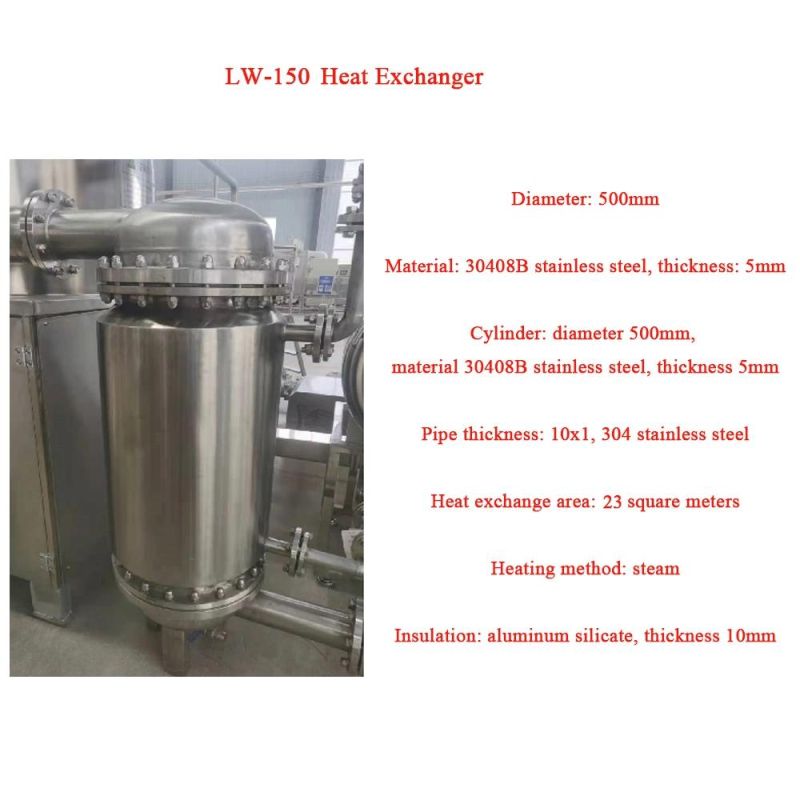

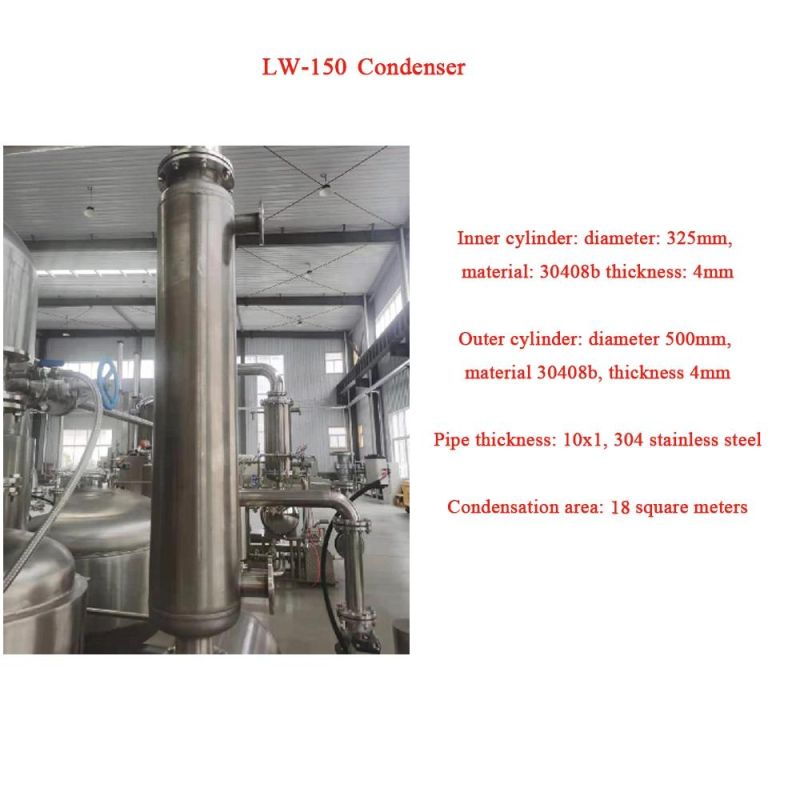

Main parts

5. The Processing Process:

Raw material → filtration → cleaning → slicing (cutting into sections) → finalizing → draining → vacuum crushing → quick freezing → vacuum frying → vacuum deoiling → seasoning → product packaging → warehousing

The Support Equipments of Vacuum Frying Processing Line

The Support Equipments of Vacuum Frying Processing Line

6. Details Components of LW-150 Vacuum Fryer

7. The Components of Vacuum Frying Machine

| Name | Brand |

| PLC | Siemens |

| Touch screen | Siemens |

| Frequency converter | Siemens |

| Temperature control module | Siemens |

| Pressure control module | Siemens |

| Switching Mode Power Supply | Schneider |

| Small relay | Schneider |

| Circuit breaker | Schneider |

| AC contactor | Schneider |

| Emergency stop switch | Schneider |

| Key switch | Schneider |

| Warning light | Schneider |

| Solenoid valve | AirTAC |

| Conflux board | AirTAC |

| Air filter | AirTAC |

8. The Package of Vacuum Frying Machine

The equipment will be assembled and disassembled as a whole according to the vacuum kettle, oil storage tank, heat exchanger, condenser and other parts, so as to facilitate customers' self-assembly and packing in wooden cases.

9. Factory Introduction:

Shandong Liwei group is a scientific and technological innovation enterprise specializing in the manufacturing of heating, drying, sterilization and vacuum low-temperature dehydration equipment. The company is guided by the world's cutting-edge R & D. It has won the honor of "specialization and innovation" in Shandong Province for many times. It is a "national high-tech enterprise".

The company was established in September 2014 with a registered capital of 20 million yuan. In 2020, the enterprise's sales revenue exceeded 200 million yuan. At present, it has 63 independent patented technologies and more than 200 employees, including more than 60 professional R & D personnel.

Our company has established and improved a strict quality standard inspection system and passed ISO9001 quality management system certification, EU CE quality system certification, intellectual property management system certification, etc.

10. FAQ

1.Are your company a trading one or a factory?

Factory + trade (integration), 21 years' focusing on insulating glass processing equipment and curtain wall equipment.

2.After an order is placed, when to deliver?

45 working days for whole production line, 30 working days for single machine. Special requirement please check with sales.

3. Guarantee ?

12 months guarantee (wearing parts are out of this range). Life long service. BOKE will send engineers for service upon request onsite.

4.What about the services and product' quality?

Each machine must be carried out 100% quality examination and test before shipment.

And all machines meet ISO and CE certification.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23