Milk Pasteurizer Machine for Sale Condensed Sweetened Milk Sweetened

Shanghai Yongguan Adhesive Products Corp., Ltd. / 2022-07-04

- After-sales Service:Engineers Availabe Over Sea

- Warranty:12months

- Power Source:Electric

- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Milk, Yogurt, Milk Powder, Cheese

=== Base Info ===

- Customized:Customized

- Project:Complete Milk Yogurt Processing Line Machine

- Manufactured:Shanghai Jimei Food Machinery Co., Ltd

- Producing:All Kinds of Milk Products

- Processing:Complete Production Line

- Capacity:200L to 20000L Per Hour

- Work:Full Automatic

- Control:PLC, Touch Screen

- Run:Stable and Reliable

- Energy Consumption:Low

- Transport Package:Packed in Nylon Cloth and Plastic Film

- Specification:CE ISO

- Trademark:Shanghai Jimei

- Origin:Shanghai, China

- Production Capacity:2 Units Per Week

=== Description ===

Basic Info.

Customized Customized Project Complete Milk Yogurt Processing Line Machine Manufactured Shanghai Jimei Food Machinery Co., Ltd Producing All Kinds of Milk Products Processing Complete Production Line Capacity 200L to 20000L Per Hour Work Full Automatic Control PLC, Touch Screen Run Stable and Reliable Energy Consumption Low Transport Package Packed in Nylon Cloth and Plastic Film Specification CE ISO Trademark Shanghai Jimei Origin Shanghai, China Production Capacity 2 Units Per WeekProduct Description

keywords:

condensed milk procesisng line

sweetened condensed milk produciton line

evaporated milk processing plant

We are looking for sole agent for each country, please contact us if you are interested.

The whole condensed milk production line consists of the following unit

Evaporated milk

- The raw milk is transported from the dairy farm to the plant in refrigerated tank trucks. At the plant, the milk is tested for odor, taste, bacteria, sediment, and the composition of milk protein and milk fat. The composition of protein and fat is measured by passing the milk under highly sensitive infrared lights.

The milk is piped through filters and into the pasteurizers. Here, the milk is quickly heated in one of two ways. The High Temperature Short Time method (HTST) subjects the milk to temperatures of 161 °F (71.6°C) for 15 seconds. The Ultra High Temperature (UHT) method heats the milk to 280°F (138°C) for two seconds.

Both methods increase the milk's stability, decrease the chance of coagulation during storage, and decrease the bacteria level.

The warm milk is piped to an evaporator. Through the process of vacuum evaporation, (exposing a liquid to a pressure lower than atmospheric pressure) the boiling point of the milk is lowered to 104-113°F (40-45°C). As a result, the milk is concentrated to 30-40% solids. Also, the milk has little or no cooked flavor.

4.The milk is then homogenized by forcing it under high pressure through tiny holes. This breaks down the fat globules into minute particles, improving its color and stability.- Pre-measured amounts of a stabilizing salt, such as potassium phosphate, are added to the milk to make it smooth and creamy. This stabilization causes the milk to turn a pale tan.

- The milk is passed under a series of ultraviolet lights to fortify it with Vitamin D.

- The milk is piped into pre-sterilized cans that are vacuum-sealed.

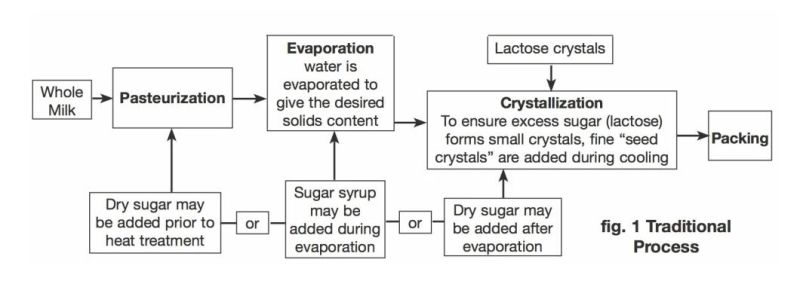

Condensed milk

- The milk is flash-heated to about 185°F (85°C) for several seconds. It is then piped to the evaporator where the water removed.

- The milk is then concentrated under vacuum pressure until it measures between 30-40% solid. It now has a syrupy consistency.

- The milk is cooled and then inoculated with approximately 40% powdered lactose crystals. The milk is then agitated to stimulate crystallization. It is this sugar that preserves the condensed milk.

- The milk is piped into sterilized cans that are then vacuum-sealed

the equipment that needed in the processing

Milk reception or powder dissolving mixing section

Mixing and sugar melting section

Pasteurizer and homogenizer

Milk storage or yoghurt producing unit

Vacuum concentration equipment

Crystal tanks

Filling or packing unit

CIP cleaning systems

After treatment equipment, like conveyor, package or pallet etc

There are other assistant equipments used such as steam boilers, air compressor, cold water unit etc

Installation materials for thematerial and non-material as well as electrical installation are provided

Specifications of condensed milk production line

Capacity of plant: 2T-300T/D.

Products type: 1 or 2 or more kinds.

Filling types can be decided by the customer then deigned accordingly.

Our company can design customized milk production lines in accordance to the customers'requirements

| Working capacity | from 5 tons/d up to 100 tons/d |

| Products | - Sweetened condensed milk |

| - Evaporated milk without sugar | |

| - Condensed milk in varied package: | |

| Can, aseptic paperboard packages, | |

| big barriers; etc. |

Consumer Notice.

If you want to buy this yoghurt production line,please tell me your requirements.

1.What is your raw material,fresh milk or milk powder?

2.What is your production capacity?

3.What is your package,carton,bottle,cup or other?

Tell me these,our engineer will design a complete project for you.We are manufacturer,if you come to Shanghai,you can come to visit our company,we have the machines to show you.

OUR FACTORY

OUR TEAM

Consumer Notice.

Our engineer will make proposal based on your requirement .please help answer below questions.

We are manufacturer,factory inspection is available all of the time.

1.What is your raw material,fresh milk or milk powder?

2.What is your production capacity?

3.What is your package,carton,bottle,cup or other?

4.your milk is UHT or pasteurized milk?

5.could you send a picture of your packing way, showing the material, the volume,and the size?

Patents and certificates

OUR EXHIBITION

COMPANY PARTY

WHO TRUST US

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23