High Precision Metal Soldering System Appearance PE-W300

Zhangpu Guangguang Plastic Products Co., Ltd. / 2022-06-23

- After-sales Service:Online Support

- Warranty:1 Year

- Application:Biomedicine, Electronic Industry, Automotive Industry, Powder Metallurgy, Manufacturing Industry

- Technical Class:Continuous Wave Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

=== Base Info ===

- Model NO.:PE-W300

- Laser Classification:YAG Laser

- Type:Automatic Laser Welding Machine

- Single Pulse Energy:90j

- Pulse Width:0.3-20ms

- Wavelength:1064nm

- Max. Output Power:9kw

- Adjusting Facular Size:0.2-2mm

- Electrical Source:220V,50Hz,40A

- Welding Frequency:0.5-40Hz

- Standard Working Table:800*1000mm

- Positioning:Optional CCD+ Red DOT

- Machine Delivery Time:7-10 Working Days

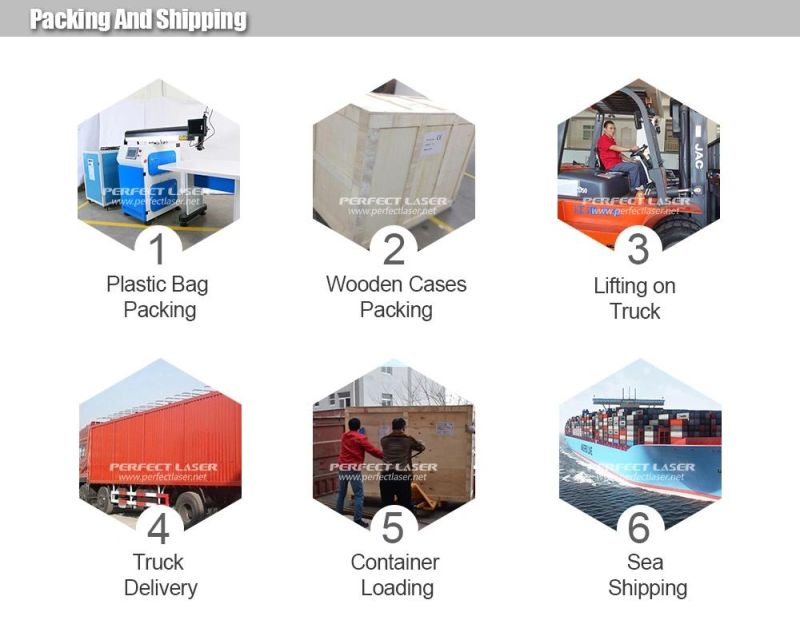

- Transport Package:Compound Wooden Cases

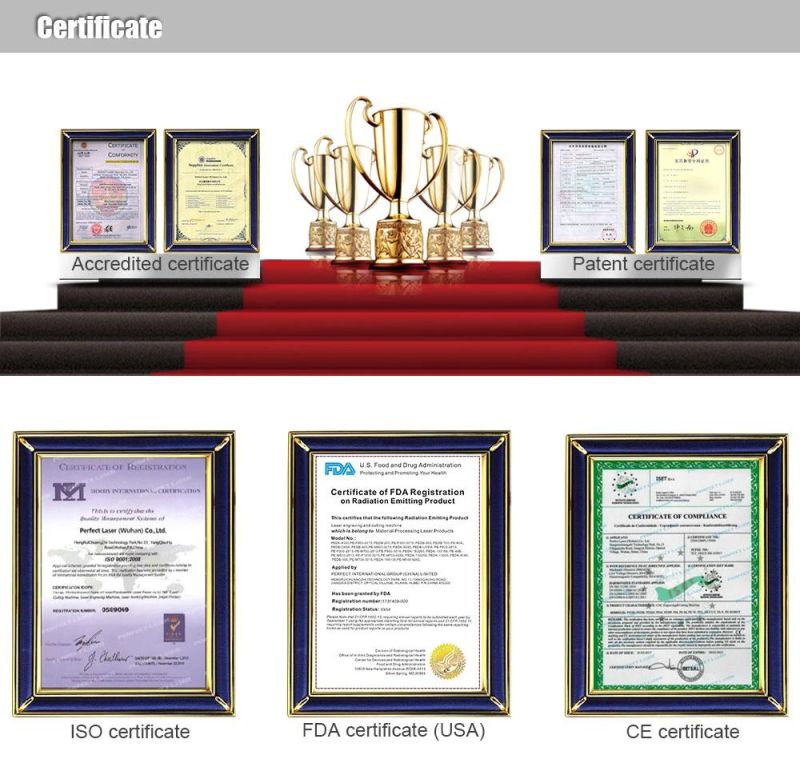

- Specification:CE, ISO

- Trademark:Perfect Laser

- Origin:Wuhan, China

- HS Code:8515809090

- Production Capacity:2000 Sets

=== Description ===

Basic Info.

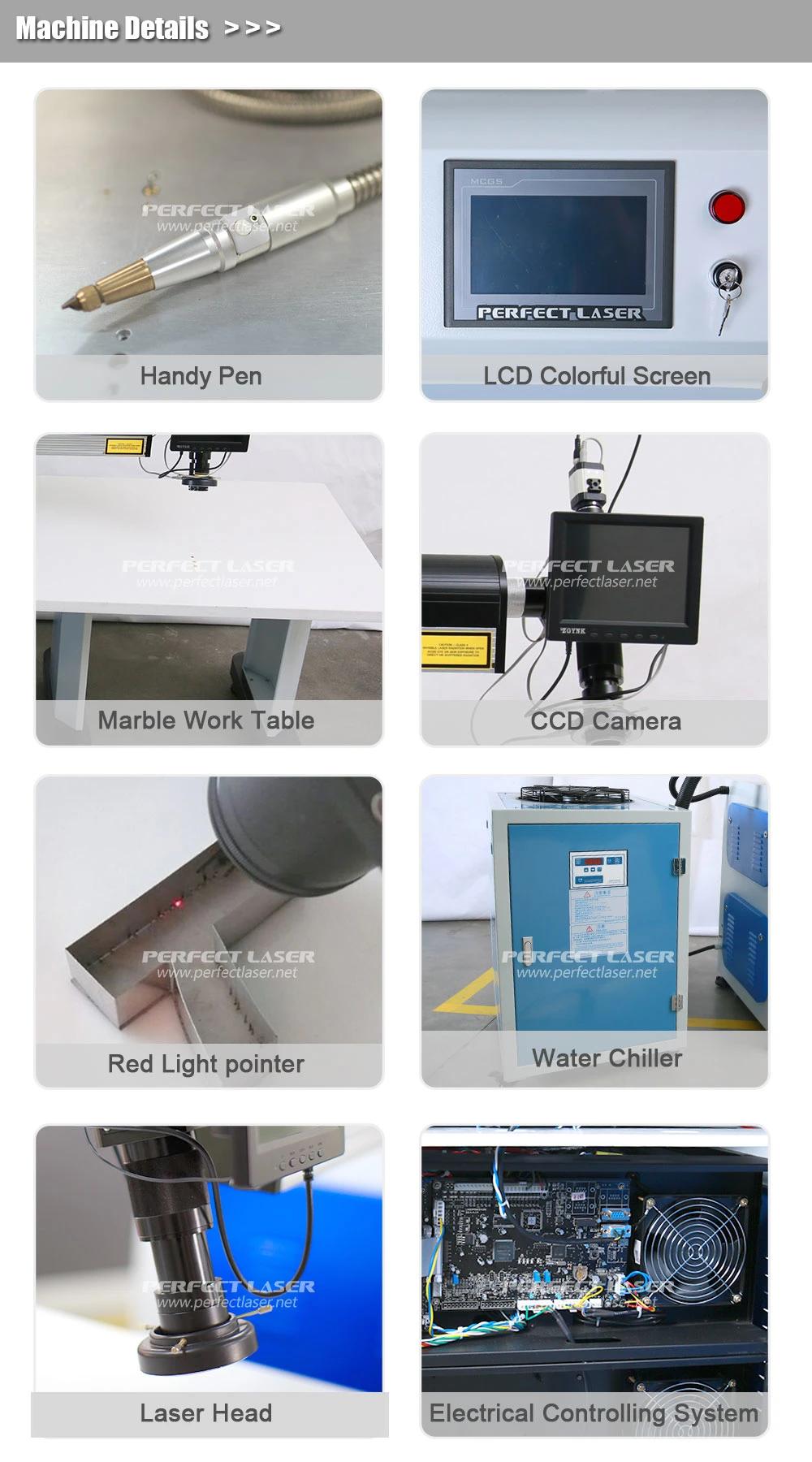

Model NO. PE-W300 Laser Classification YAG Laser Type Automatic Laser Welding Machine Single Pulse Energy 90j Pulse Width 0.3-20ms Wavelength 1064nm Max. Output Power 9kw Adjusting Facular Size 0.2-2mm Electrical Source 220V/50Hz/40A Welding Frequency 0.5-40Hz Standard Working Table 800*1000mm Positioning Optional CCD+ Red DOT Machine Delivery Time 7-10 Working Days Transport Package Compound Wooden Cases Specification CE, ISO Trademark Perfect Laser Origin Wuhan, China HS Code 8515809090 Production Capacity 2000 SetsProduct Description

High Precision Metal Soldering System Appearance PE-W300Product Introduction

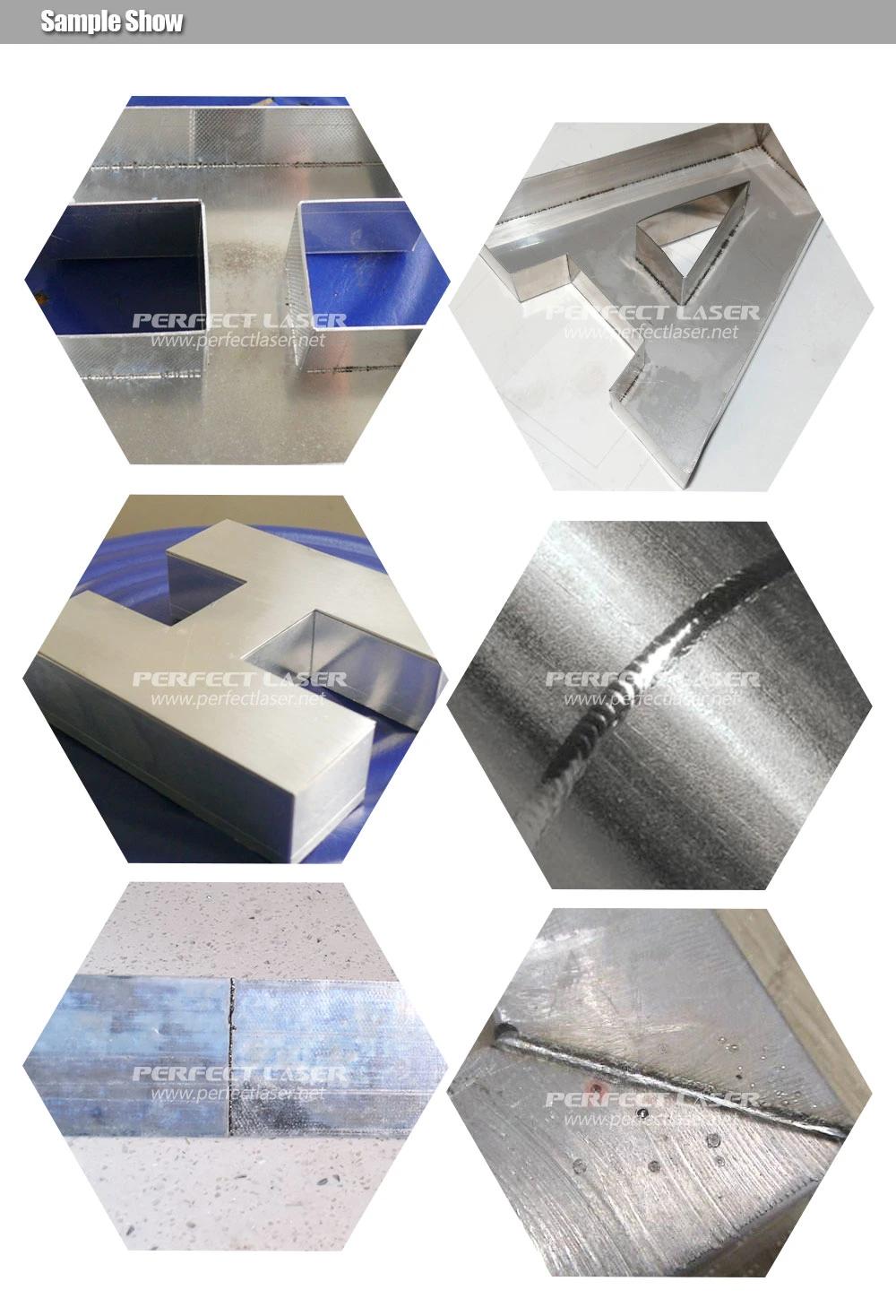

Laser beam transmitted by fiber which set on the top of solder ball exit. It set an entrance for high pressure gas on the top of circle cavity, the solder ball will be melted by laser beam, and then the high pressure inert gas will force the melted tin drop, it can also ensure that the melted tin will not be oxidized. This laser soldering system provides accurate and perfect soldering effects, which especially suitable for high precision soldering.

Product Features

1. Constant temperature on soldering spot

2. Easy to set soldering temperature, directly input the figure, without any more experiments to prove.

3. Temperature of soldering point can be continuously adjusted from 100-600 ºC

4. Temperature controlling accuracy within 5 ºC

5. Coaxial CCD imaging, real-time monitoring of soldering spot

6. Local heating with least heat influence on the surroundings.

7. Easy to set processing program, convenient for operation.

8. Optical coaxial of the laser output, the CCD monitor, and the temperature feedback, avoided complicated adjustment and calibration, perfectly solved the superposition of the soldering, guiding, and the imaging spot

9. Continuous gradient heating can be realized by programmable software adjustment.

10. Perfect soldering effects, with full and constant soldering spot.

11. Advanced automation. You can watch the processing imagine while it shows on CCD. You can also add automatic visual identifiable alignment system to realize automatic production.

12. Non-contact processing, without mechanical extrusion to the soldering spot.

13. Accurate soldering, beam spot can be as fine as micron, soldering time can be controlled by program, and the soldering accuracy is much higher than traditional processing way.

14. Fine laser beam replaces iron head, which is easy to solder when there are obstacles on the surface of the soldering point.

Applications

It is suitable for PCB point soldering, metal, non-metallic materials soldering, plastic welding, and other applications of sintering and heating, as well as automatic production on special soldering spot processing in pipeline production. For its features of real time and accurate temperature-control on target soldering points, it is specially suitable for processing high sensitive materials, which needs high precision soldering.

Training, Commissioning & Start up of Machine

1. We will supply with the machine Operation Manual and Training CD in English version for: Installing and operation, including introduction for the composing of equipment, working principle of equipment, common knowledge of computer, controlling principle of electronic devices, daily maintenance measures of equipment. Personal demonstration for installation, adjusting and operation of equipment, and the computer. Common malfunction eliminating measures, etc.

2. We will supply Instruction for simple troubleshooting of the machine when dispatching, which can help you dealing with the common problems happened unluckily. Also, one set of "Instruction Book", "Operation Manual" and "Training Video Disk" for machine/software will be sent to you along with the machine, which could be easily understood and friendly handled by you and your customers.

Quality Guarantee Services and After-sale Services

1. The guarantee period of quality shall be 12 months counting from the date on which the commodity arrives at the port of destination.

2. Except the damage artificially and laser crystal rod and laser lamp, we are responsible for offering the fittings free of charge during the guarantee period, while it is preferred you send the damaged fittings to us by courier with your charge for our testing, after confirming damage, we will send back the alternative fittings to you. After the guarantee of quality period, the parts required repairing or change, if any, shall be paid.

3. When you meet some complicated problem and online-support can not solve it, we can offer Door-Visiting Service. If our engineer to assemble or/and maintain or/and adjust the machine is/are required, we shall assist to deal with the visa formality and prepaid traveling expenses and accommodation to us during the business trip and the service period before their dispatch. And you can arrange for the translating person for the service engineer during their service period. Or you can send your engineer to China. We will offer long-term technical training to him for free.

Remark

1. Payment Terms: T/T before delivery.

2. Production Lead Time: 7-15 working days after receipt of the advance payment.

3. Delivery Method: By sea (please indicate the destination port).

4. Packing: Compound wooden cases comply with international exporting standard.

Any interest? Welcome to contact me now!

Contact me:

Perfect Laser Co., Ltd. (China)

Contact: Emma / Sales Department

Mob +8613886034275

Add: HengRuichuangzhi Technology Park, No.13 YangQiaohu Road, Jiangxia District, Optical Village, Wuhan, Hubei, China(430200).

Tel: 0086-27-86791986 Fax: 0086-27-86775865

Welcome to contact us for further information!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23