Focuslaser Jewelry Laser Welding Machine

Zhenjiang Norman Import & Export Co., Ltd. / 2022-06-23

- Laser Visibility:Invisible

- Applicable Material:Metal

- Cooling System:Air Cooling

- Technical Class:Continuous Wave Laser

- Laser Wavelength:Fiber Laser

- Laser Classification:Semiconductor Laser

=== Base Info ===

- Model NO.:FL-70PW

- Type:Optical Fiber Laser Marking Machine

- Marking Method:Scanning Marking

- Model:Laser Marking Machine

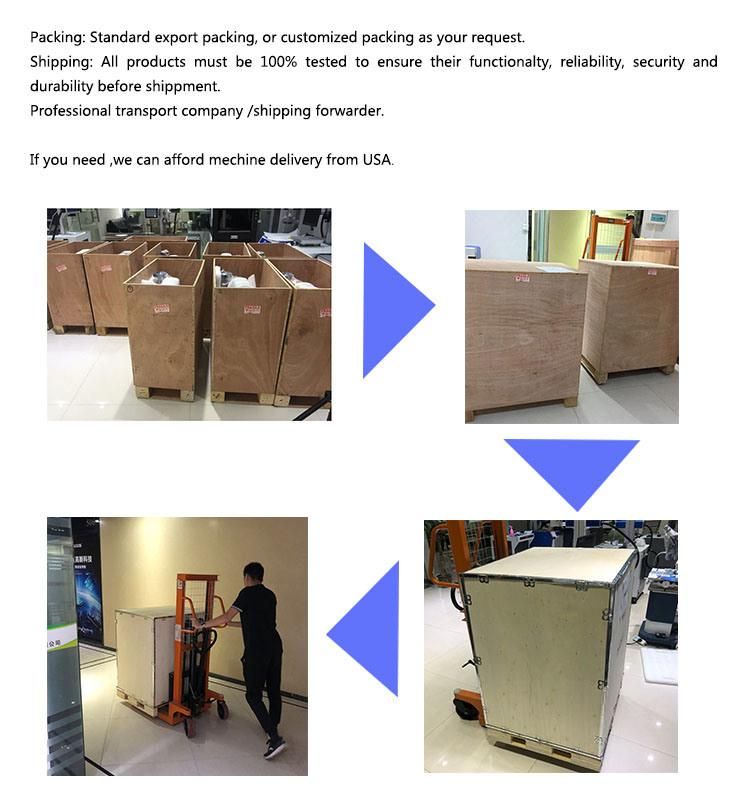

- Transport Package:Export Box

- Specification:450x300x350mm

- Trademark:FOCUSLASER

- Origin:China

- HS Code:84561000

- Production Capacity:2000 Set,Year

=== Description ===

Basic Info.

Model NO. FL-70PW Type Optical Fiber Laser Marking Machine Marking Method Scanning Marking Model Laser Marking Machine Transport Package Export Box Specification 450x300x350mm Trademark FOCUSLASER Origin China HS Code 84561000 Production Capacity 2000 Set/YearProduct Description

Parameters| Input Voltage | AC220V±10% 50Hz |

| Laser Frequency | 1.0~10.0Hz Continuously Adjustable |

| Pulse Width | 0.1~10.0ms Grading Adjustable |

| Spot Diameter Adjusting Scope | ±3.0mm |

| Laser Output Power | ≤65W |

| Aiming and Positioning | CCD and Microscope |

| Environmental Temperature | ≤45ºC |

| Operating Mode | Touch Control |

| Laser Wavelength | 1064nm |

| Display touch screen mounting dimensions | 137*190(mm) |

| Machine Dimensions | L 510*W 295*H 395(mm) |

Focuslaser Jewelry Welding laser machine Jewelry welding spot welding machine welding tools

Thank you for choosing the FOCUSLASER portable Jewelry laser welding machine, which will provide you with excellent performance, High quality, efficient welding service. It is easy to operate.

In order to get the best results from your machine, please read these operating instructions carefully before use.

Equipment use precautions:

1. The machine working voltage is AC220V/50Hz and capacity 10A.

2. Since the main components of the machine are optical components, in order to keep them clean, it should be ensured the installation room is dry and clean, free from dust or less dust, preferably in an air-conditioned environment.

3. There is a high voltage inside the machine. Do not open the power supply chassis without authorization to prevent electric shock.

4. Ensure that the equipment casing is safely grounded.

5. Please ensure that the water tank is full of water before starting the machine, and regularly change purified water tanks every month to ensure the water tank clean.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23